Efficient disturbance rotary incinerator

A rotary, incinerator technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as inability to meet waste incineration process treatment methods, uncontrollable waste residence time, and difficulty in temperature-controlled combustion. Good stability, high level of automation, and the effect of ensuring turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

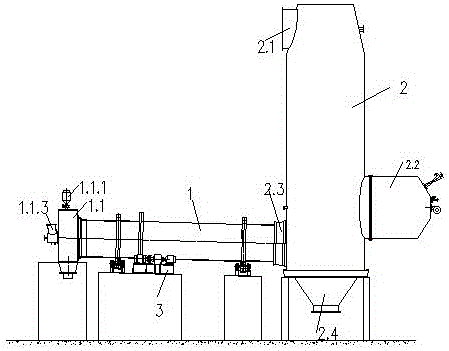

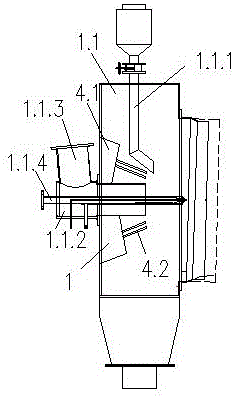

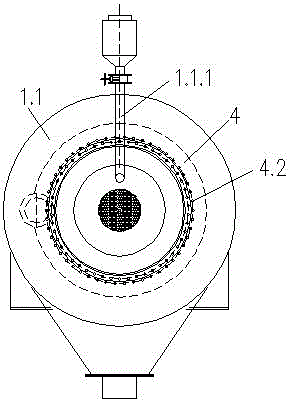

[0017] Embodiment 1: A high-efficiency disturbance rotary incinerator, including a furnace body, the furnace body includes a vertically arranged No. 2 combustion chamber 2 and a horizontally arranged No. 1 combustion chamber 1, and the vertical No. 2 combustion chamber 2 includes a vertical type cylinder body, smoke outlet 2.1 installed at the top of the vertical cylinder body, No. The gas inlet 2.3 and the cone-shaped ash outlet 2.4 at the bottom of the vertical cylinder body, the No. 1 combustion chamber 1 includes the cylinder body, and the No. 1 fire storage chamber 1.1 arranged at the front end of the cylinder body. The end of the cylinder body is connected to the flue gas inlet 2.1. The outer side of the No. 1 combustion chamber 1 cylinder body is provided with a rotating device 3 that can rotate the cylinder body. The No. 1 fire storage chamber 1.1 includes a cylindrical warehouse body. The left center is provided with an air volume regulating pipe 1.1.2, and one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com