Drying machine and dish washing machine

A technology of drying device and exhaust motor, which is applied to the parts of washing machine/rinsing and washing machine for tableware, etc. It can solve the problems of potential safety hazards, high energy consumption, and poor drying effect, so as to improve the drying effect and reduce energy consumption , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

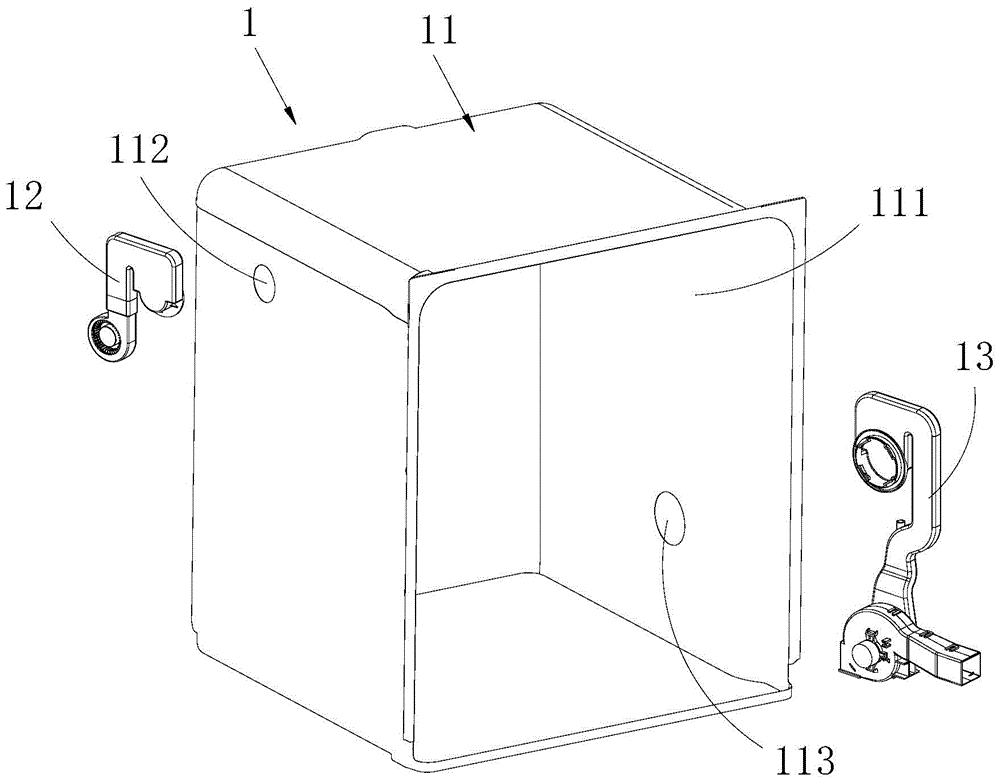

[0026] Such as Figure 1-10 Shown is a preferred embodiment provided by the present invention.

[0027] The drying device 1 provided in this embodiment can be used in a dishwasher, of course, it can also be used in other equipment, such as some equipment that needs to dry the inner cavity 111, can be operated by using the drying device 1, And it's not just limited to dishwashers.

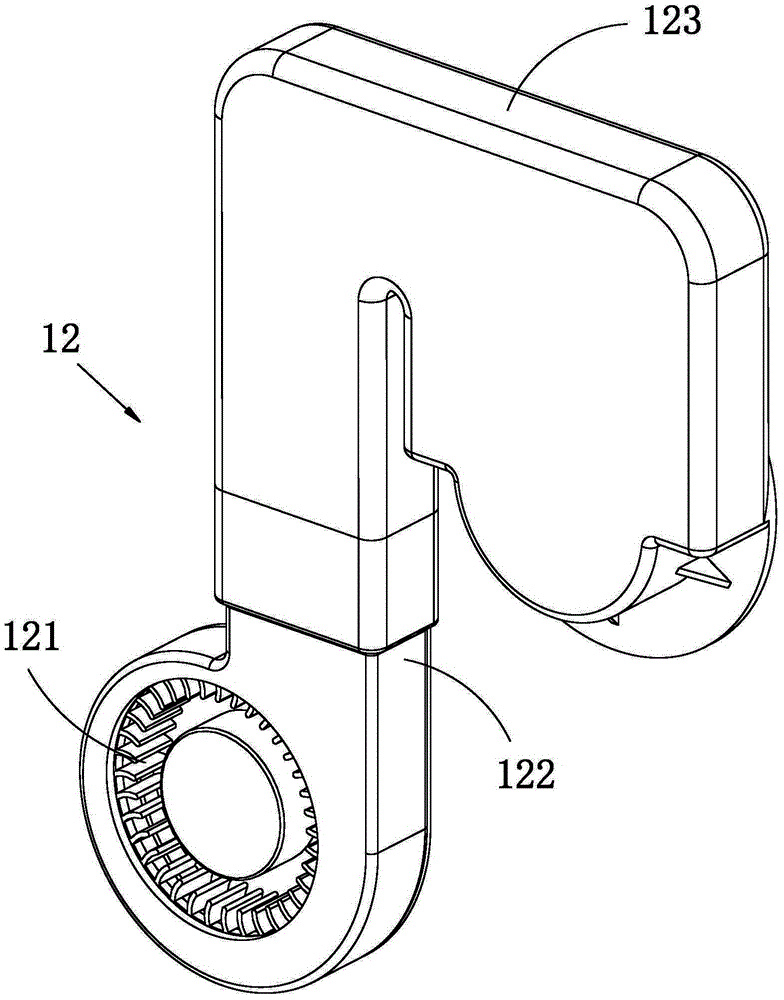

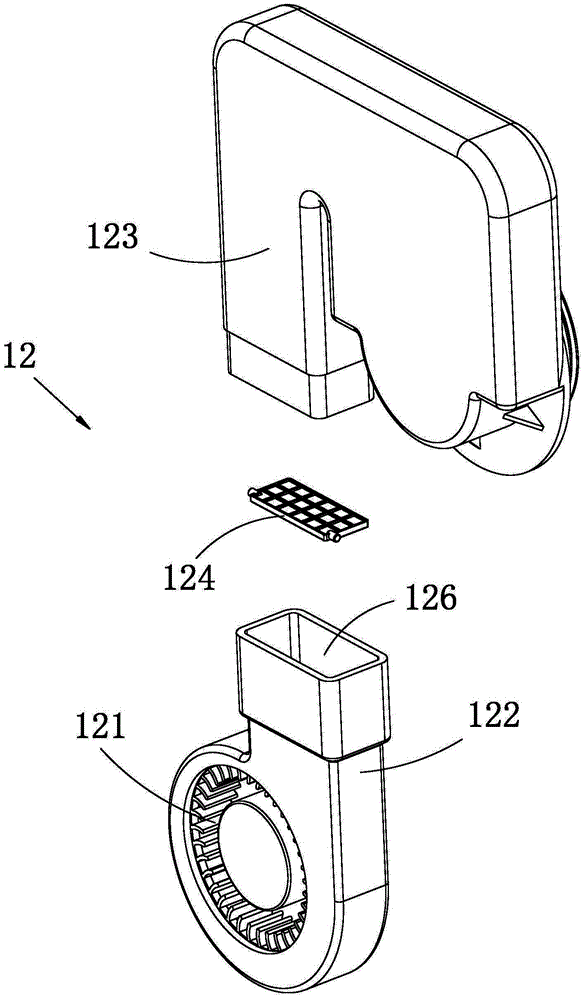

[0028] The drying device 1 comprises an inner container 11, an air inlet mechanism 12 and an exhaust mechanism 13, wherein the inner container 11 is in a square shape, and a cavity 111 is provided therein, and one side of the cavity 111 has an opening, and objects to be washed can be placed in the In the cavity 111 of the inner container 11, thereby, utilize other components to close the opening of the cavity 111, then the inner container 11 can be in a closed state, and steam can be used to wash the objects to be washed in the cavity 111; The shape of the bladder 11 is not limited to the above-me...

Embodiment 2

[0061] Such as Figures 11 to 14 Shown is another preferred embodiment provided by the present invention.

[0062] The difference between this embodiment and Embodiment 1 is:

[0063] In this embodiment, the baffle 124 is arranged in the connecting port 120 of the air duct 123, and the step 129 is also arranged in the connecting port 120, the baffle 124 can be abutted on the step 129, and one side thereof is hingedly arranged, thus, The baffle 124 can swing in the connection port 120 to realize the closing or opening of the air duct.

[0064] Specifically, a hinge seat 127 is provided on the step 129, and a pin shaft 128 extends outward from one side of the baffle plate 124, so that the pin shaft 128 is hinged in the hinge seat 127 to realize the hinge arrangement on one side of the baffle plate 124. . Such as Figure 13 As shown, it is a schematic diagram of the air passage closed by the baffle plate 124, such as Figure 14 Shown is a schematic diagram of the baffle 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com