Construction safety helmet

A safety helmet and liner technology, which is applied in the field of construction safety helmets, can solve problems such as the hot and humid air environment of the safety helmet, the inability to make vent holes on the surface of the shell, and the damage to the mechanical comfort of the head, so as to improve the hot and humid harsh environment, Improve mechanical comfort and uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

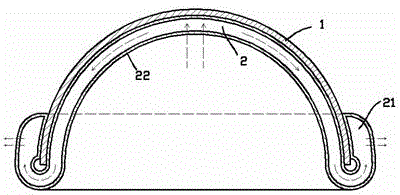

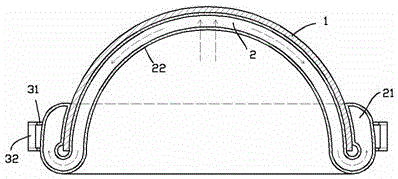

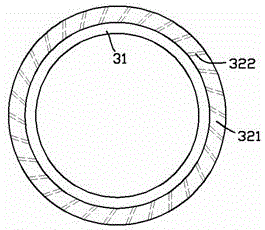

[0014] exist figure 1 In the first embodiment shown, the construction safety helmet includes a hemispherical hard shell 1 and an inner tank 2; the inner tank 2 is hemispherical inside the outer shell 1 and is lined on the inner surface of the outer shell 1, and The liner 2 goes around the periphery of the shell and rolls up to form a flange 21 that wraps the shell 1 tightly; the inside of the liner 2 is a hollow cavity, and the liner wall surrounding the hollow cavity is formed by elastic The thin wall 22 is formed, that is, the inner tank 2 is a cavity surrounded by a continuous elastic thin wall 22; the inner tank wall surface is evenly distributed with air holes.

[0015] In the above-mentioned construction safety helmet, the height from the lowermost end to the uppermost end of the flange 21 of the inner tank 2 is 4cm~6cm; a larger area of the windward side is formed on the outside of the flange, and when there is external wind force, a larger amount of Outside air flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com