A solid adsorbent regenerating device and an adsorption device applying the regenerating device

A technology of solid adsorbent and regeneration device, applied in the field of adsorption, can solve the problems of low temperature, easy carbon deposition on the heating surface, low thermal conductivity, etc., and achieve the effects of simple structure, reduced heat loss and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

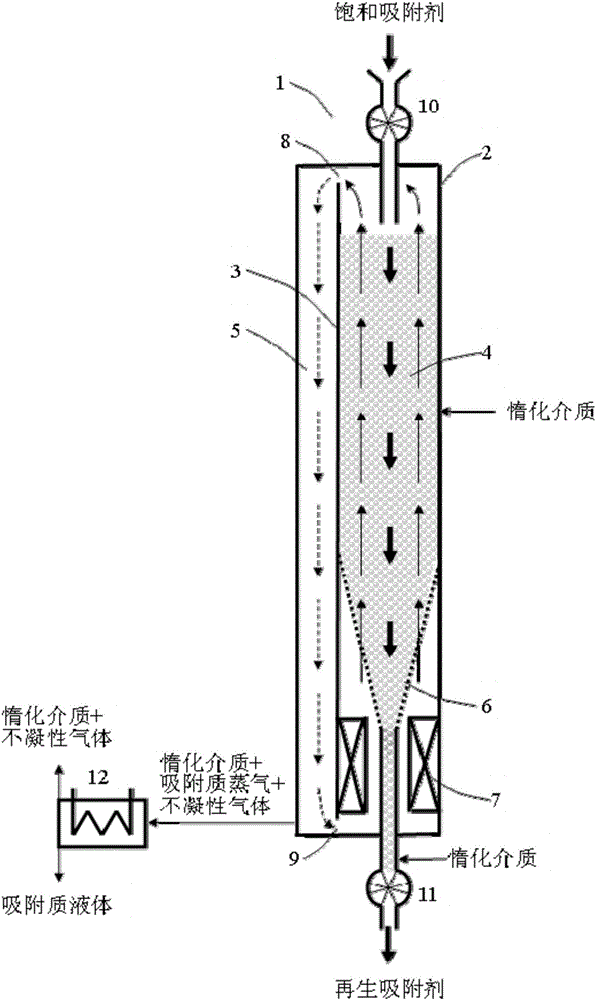

[0063] Such as figure 1 As shown, it is a structural schematic diagram of a regeneration device internally divided into two parts according to the present invention. see figure 1 , regeneration device 1 has furnace body 2, and its inside is divided into two parts by partition wall 3, and wherein one part is adsorbent bed 4, and another part is vertical gas flow channel 5, and the upper space of adsorbent bed 4 and the lower space and vertical The upper space and the lower space of the air flow channel 5 communicate through the upper vent 8 and the lower vent 9 respectively. Sorbent bed 4 bottoms are supported by ventilating funnel 6 (the shape of this ventilating funnel 6 is adapted to body of heater 2, and ventilating funnel 6 walls are provided with many apertures, and the diameter of these apertures is less than adsorbent particle diameter, makes ventilating funnel 6 The walls allow the gas to pass through, but not the adsorbent particles). Ventilation funnel 6 below is ...

Embodiment 2

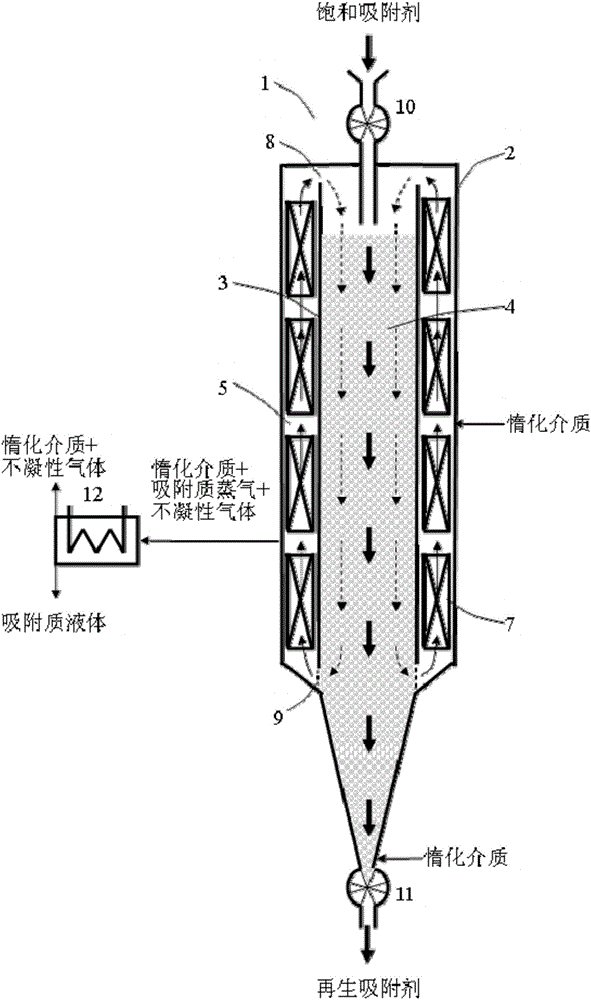

[0114] Such as figure 2 As shown, it is a structural schematic diagram of a regenerative device internally divided into three parts according to the present invention. see figure 2 , The regeneration device 1 has a furnace body 2, and its interior is divided into three parts, one of which is provided with an adsorbent bed 4, and the other two parts are provided with a series of regeneration heaters 7. The part where the adsorbent bed 4 is located is the cold side, and the part where the regeneration heater 7 is located is the hot side. The heating of the regenerative heater 7 makes the gas on the hot side flow upwards, and the gas on the cold side flows downwards, forming a circulation flow of the gas inside the regeneration device 1, transferring the heat of the regenerative heater 7 to the adsorbent bed 4, and making the adsorbent Regenerated by heating. figure 2 The thick solid line arrows in the device indicate the moving direction of activated carbon during the rege...

Embodiment 3

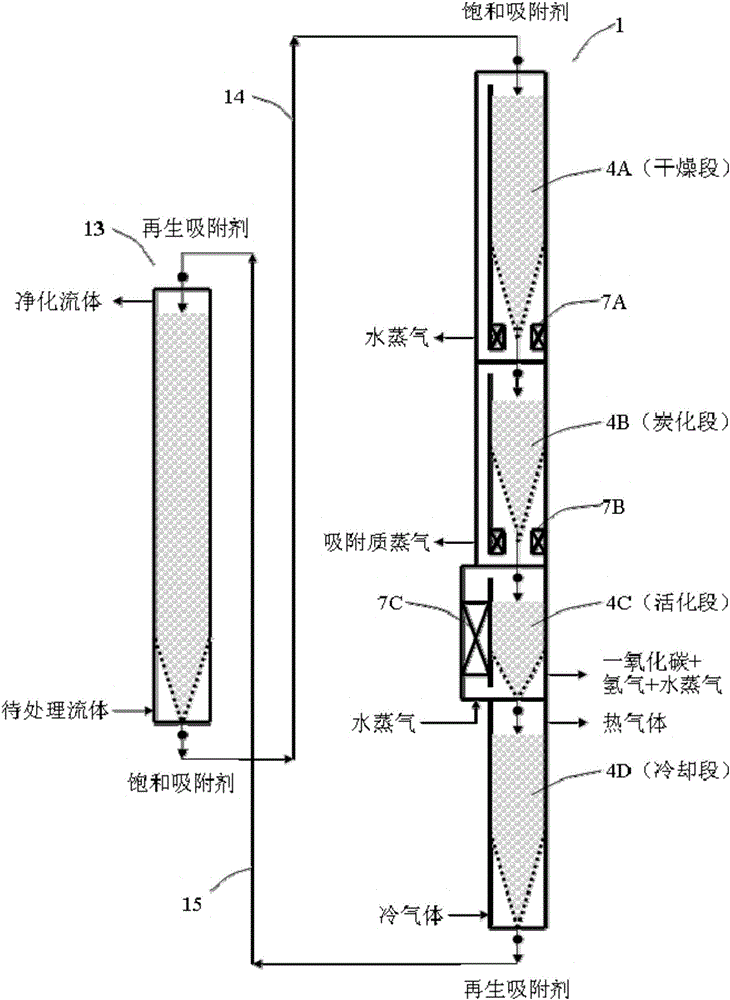

[0118] This embodiment is a multi-stage regeneration device, which is mainly used for the regeneration of liquid-phase adsorption activated carbon (such as waterworks activated carbon). see image 3 , The regeneration device 1 consists of four sections: the activated carbon moving bed 4A is the drying section, 4B is the carbonization section, 4C is the activation section, and 4D is the cooling section. 7A, 7B, and 7C are heaters for the drying section, the carbonization section, and the activation section, respectively. The structure of each section is the same as that of the regeneration device 1 described in Embodiment 1 (there is one difference: in the activation section, the heater 7C is arranged in the vertical air flow passage 5).

[0119] When the device is in normal continuous operation, the saturated adsorbent is added from the top of the regeneration device 1, and after passing through each section of the moving bed, the regenerated adsorbent is discharged from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com