Low-temperature storage tank pre-cooling system and pre-cooling method

A low-temperature storage tank and pre-cooling technology, which is applied to pipeline systems, container filling methods, fixed-capacity gas storage tanks, etc., can solve problems such as low design pressure, increased gas phase pressure, and large volume, and achieve improved efficiency and pre-cooling The effect of high efficiency and high utilization rate of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

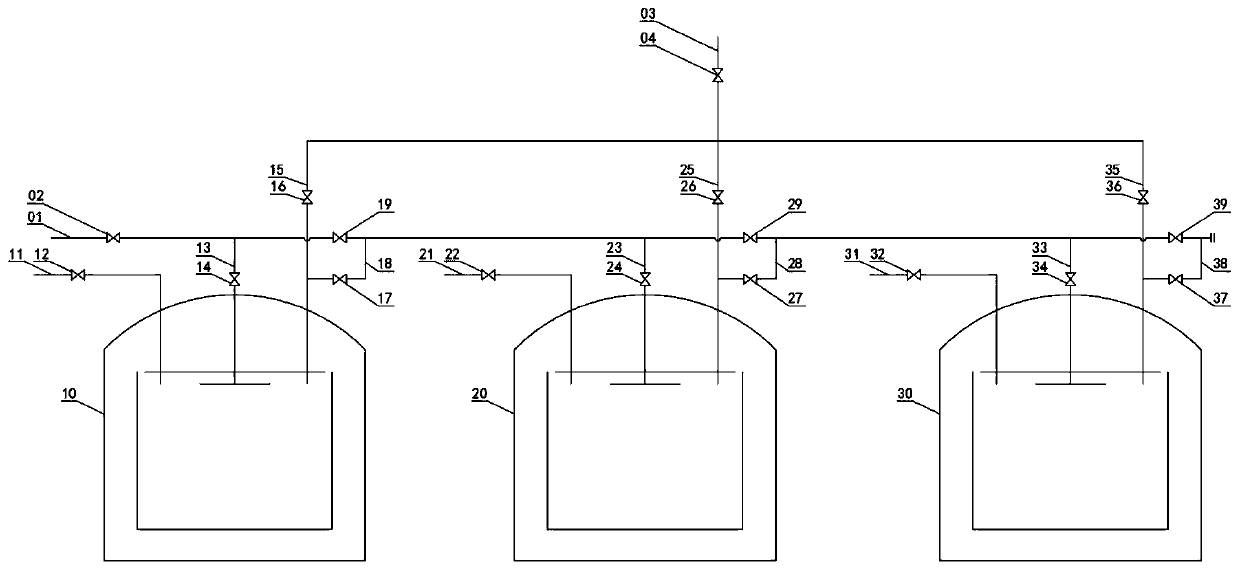

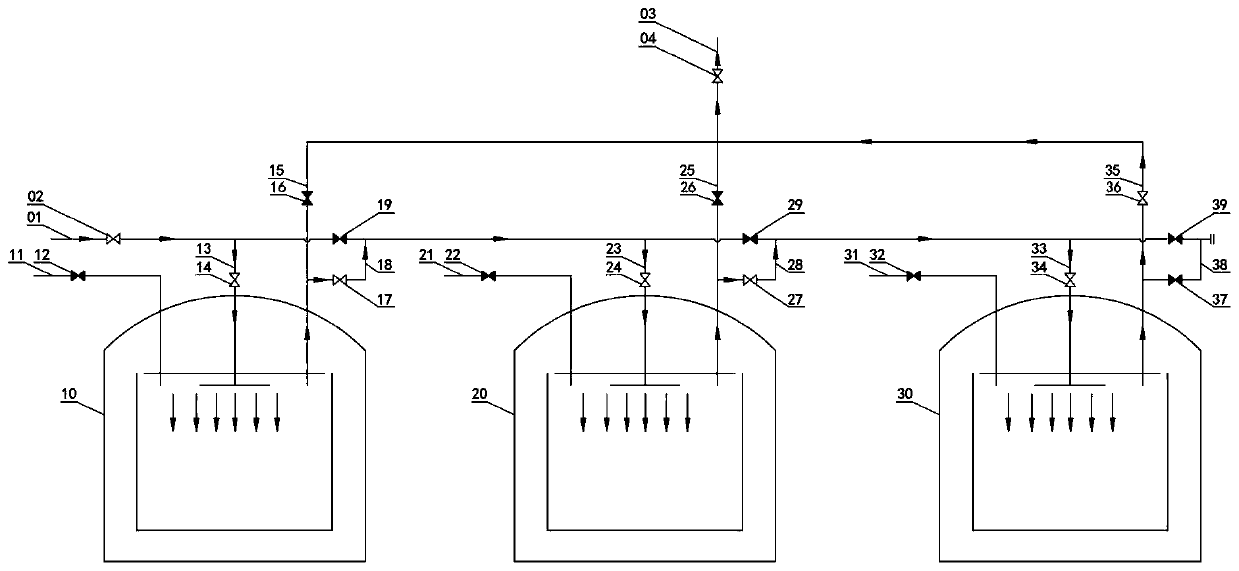

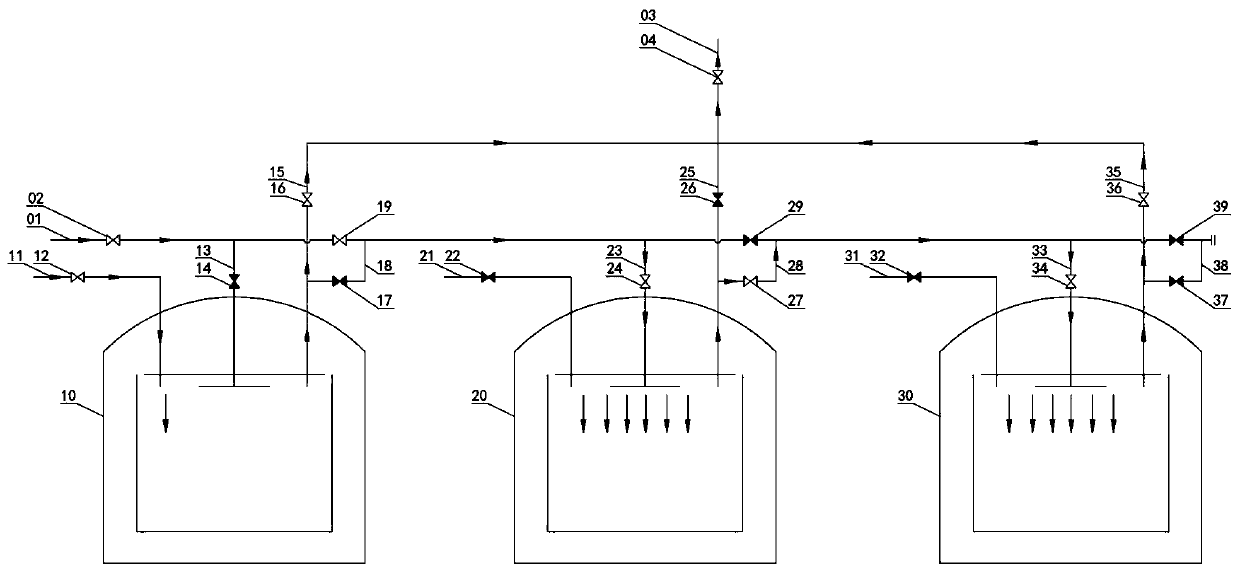

[0027] like Figure 1-5 As shown, the present embodiment is a low-temperature storage tank pre-cooling system, and its structure includes a pre-cooling main pipe 01, a pre-cooling main pipe valve 02, a gas phase exporting main pipe 03, a gas phase exporting main pipe valve 04, No. 1 low-temperature storage tank 10, No. 1 liquid inlet pipe 11, No. 1 liquid inlet pipe valve 12, No. 1 pre-cooling pipe 13, No. 1 pre-cooling pipe valve 14, No. 1 gas-phase external pipe 15, No. 1 gas-phase external pipe valve 16, No. 1 air-conditioning Jumper 17, No. 1 Air-conditioning Jumper Valve 18, No. 1 Pre-cooling Block Valve No. 2 pre-cooling pipe valve 24, No. 2 gas phase external pipe 25, No. 2 gas phase external pipe valve 26, No. 2 air-conditioning jumper 27, No. 2 air-conditioning jumper valve 28, No. 2 pre-cooling isolation valve 29, No. 3 low temperature Storage tank 30, No. 3 liquid inlet pipe 31, No. 3 liquid inlet pipe valve 32, No. 3 pre-cooling pipe 33, No. 3 pre-cooling pipe val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com