Efficient pre-cooling and liquefying system coupled with expansion mechanism and regenerative refrigerator

An expansion mechanism, regenerative technology, applied in refrigeration and liquefaction, refrigerator, liquefaction and other directions, can solve problems such as reducing pre-cooling efficiency, and achieve the effect of improving pre-cooling efficiency, promoting large-scale application, and improving liquefaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

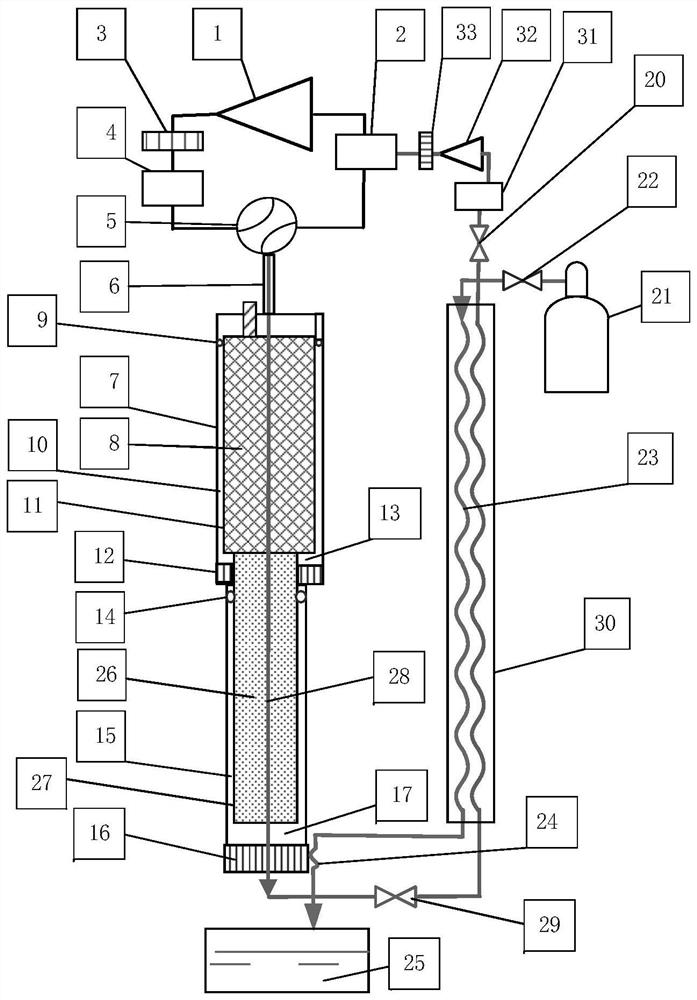

[0076] like figure 1 As shown, the high-efficiency precooling and liquefaction system coupled with an expansion mechanism and a regenerative refrigerator in this embodiment includes a two-stage GM refrigerator module, an expansion and compression module, and a liquefaction module.

[0077]The secondary GM chiller module consists of a recuperative chiller unit and a DC external circulation unit. The regenerative refrigerator unit includes compression device 1, compressor low-pressure gas storage tank 2, compressor cooler and filter device 3, compressor high-pressure gas storage tank 4, GM type compressor high and low pressure gas distribution valve 5, refrigerator inlet Air channel 6, refrigerator cylinder 7, first-stage expansion piston 11, first-stage regenerator 8, first-stage expansion piston sealing mechanism 9, gap 10 between first-stage expansion piston and cylinder, second-stage expansion piston 27 , the second-stage regenerator 26, the first-stage cold end heat exchan...

Embodiment 2

[0083] Cryogenic storage system cooled with novel regenerative refrigerator

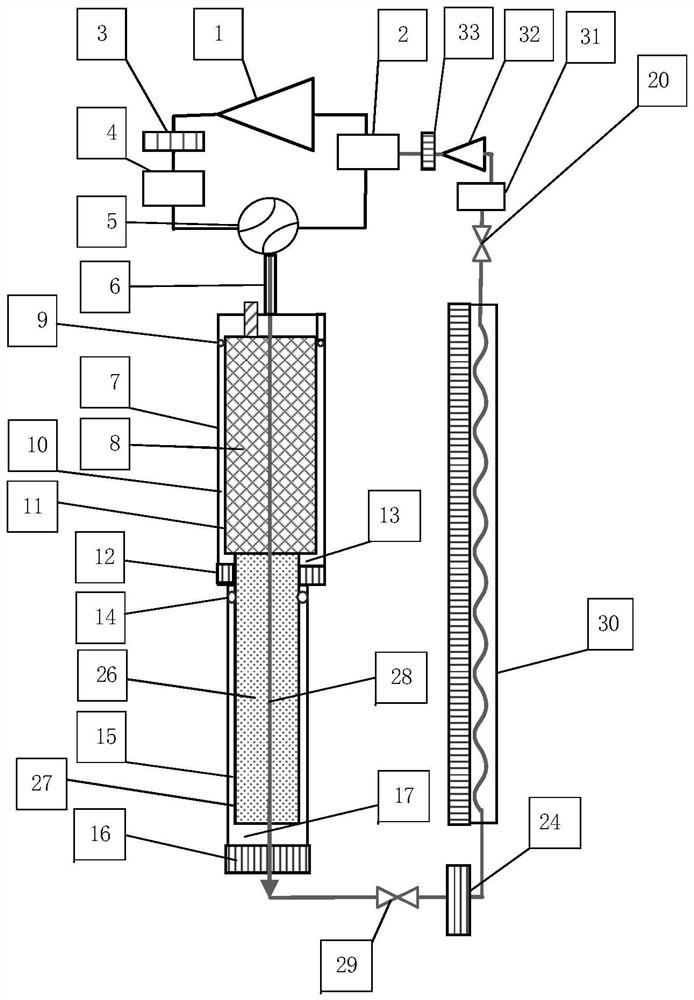

[0084] like figure 2 As shown, the high-efficiency pre-cooling system coupled with the expansion mechanism and the regenerative refrigerator in this embodiment includes a two-stage GM refrigerator module and an expansion and compression module.

[0085] The secondary GM chiller module consists of a recuperative chiller unit and a DC external circulation unit. The regenerative refrigerator unit includes compression device 1, compressor low-pressure gas storage tank 2, compressor cooler and filter device 3, compressor high-pressure gas storage tank 4, GM type compressor high and low pressure gas distribution valve 5, refrigerator inlet Air channel 6, refrigerator cylinder 7, first-stage expansion piston 11, first-stage regenerator 8, first-stage expansion piston sealing mechanism 9, gap 10 between first-stage expansion piston and cylinder, second-stage expansion piston 27 , the second-stage regenera...

Embodiment 3

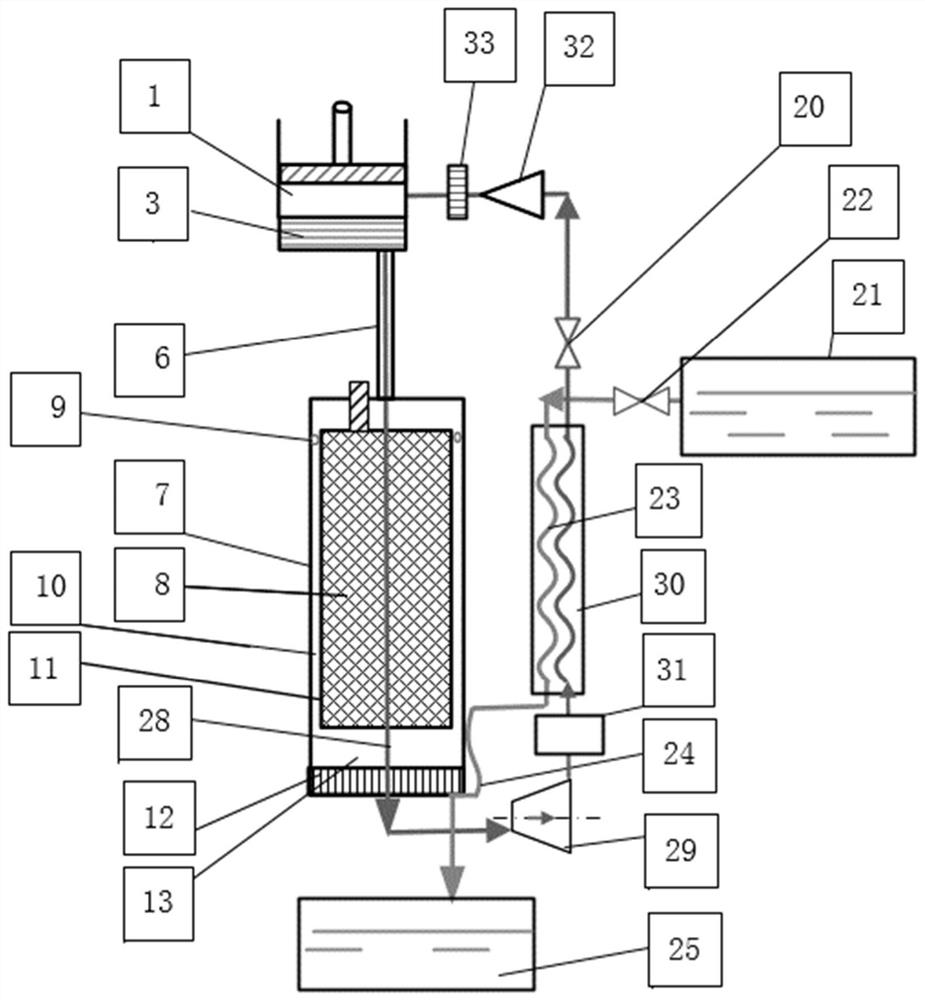

[0090] like image 3 As shown, the high-efficiency precooling system coupled with an expansion mechanism and a regenerative refrigerator in this embodiment includes a single-stage Stirling refrigerator module, an expansion and compression module, and a liquid precooling module.

[0091] The single-stage Stirling chiller module consists of a recuperative chiller unit and a DC external circulation unit. The regenerative refrigerator unit includes a piston compression device 1, a compressor cooler 3, a refrigerator air intake passage 6, a refrigerator cylinder 7, a first-stage expansion piston 11, a first-stage regenerator 8, and a first-stage expansion Piston sealing mechanism 9 , gap 10 between first stage expansion piston and cylinder, first stage cold end heat exchanger 12 , first stage expansion cavity 13 . The direct current external circulation unit includes a direct current 28 and a direct current control valve 20 .

[0092] The expansion and compression module includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com