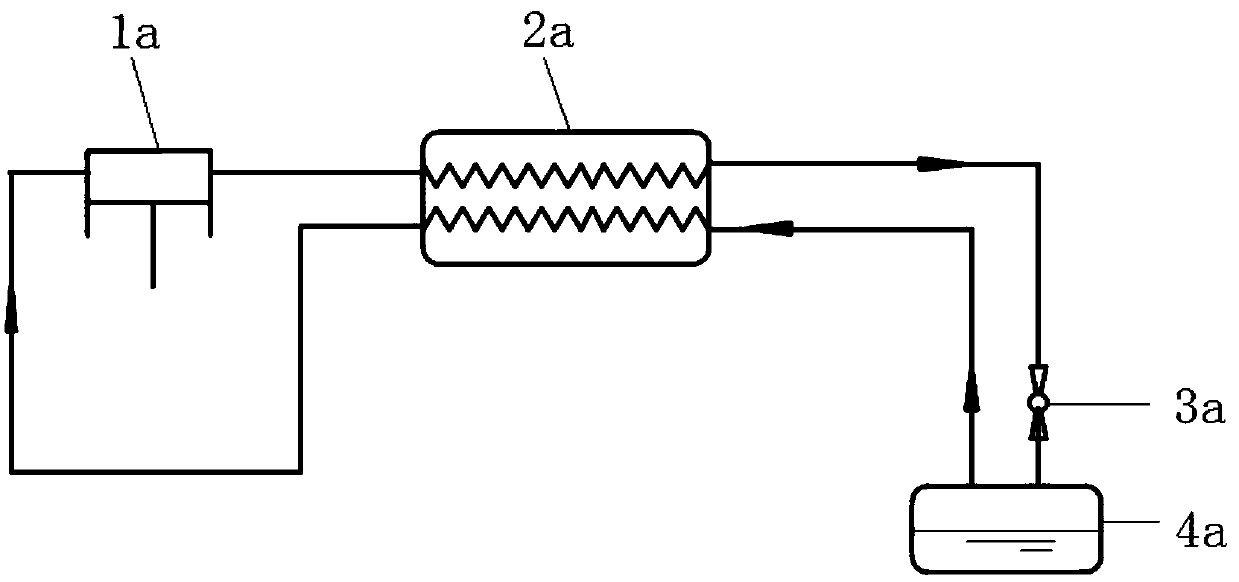

Primary throttling low-temperature refrigeration system pre-cooled by utilizing the vortex tube energy separation effect

A technology of energy separation and vortex tube, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of limited pre-cooling effect and large compressor pressure ratio, and achieve simple structure, low refrigeration temperature and pre-cooling effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

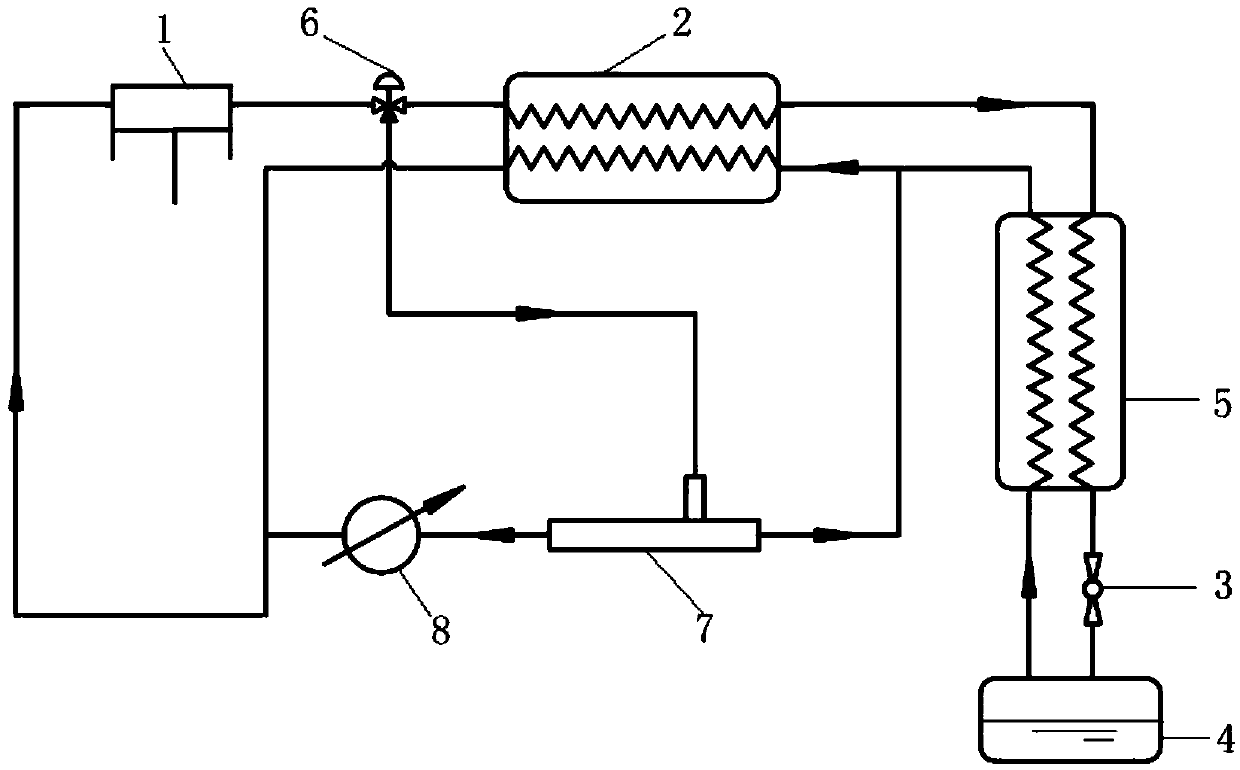

Embodiment 1

[0020] A throttling low-temperature refrigeration system for precooling using the energy separation effect of a vortex tube, comprising a compressor 1, a regenerator, a throttle valve, an evaporator 4, and a radiator 8, and the regenerator includes a first regenerator 2 and the second regenerator 5, further comprising a three-way flow regulating valve 6 and a vortex tube 7, the outlet of the compressor 1 communicates with the inlet of the three-way flow regulating valve 6, and the three-way flow regulating valve 6 The first outlet communicates with the inlet of the hot end of the first regenerator 2, the second outlet communicates with the inlet of the vortex tube 7, and the outlet of the cold end of the first regenerator 2 communicates with the hot end of the second regenerator 5. The outlet of the cold end of the second regenerator 5 is connected in series with the throttle valve 3 and then connected with the inlet of the evaporator 4, and the outlet of the evaporator 4 is co...

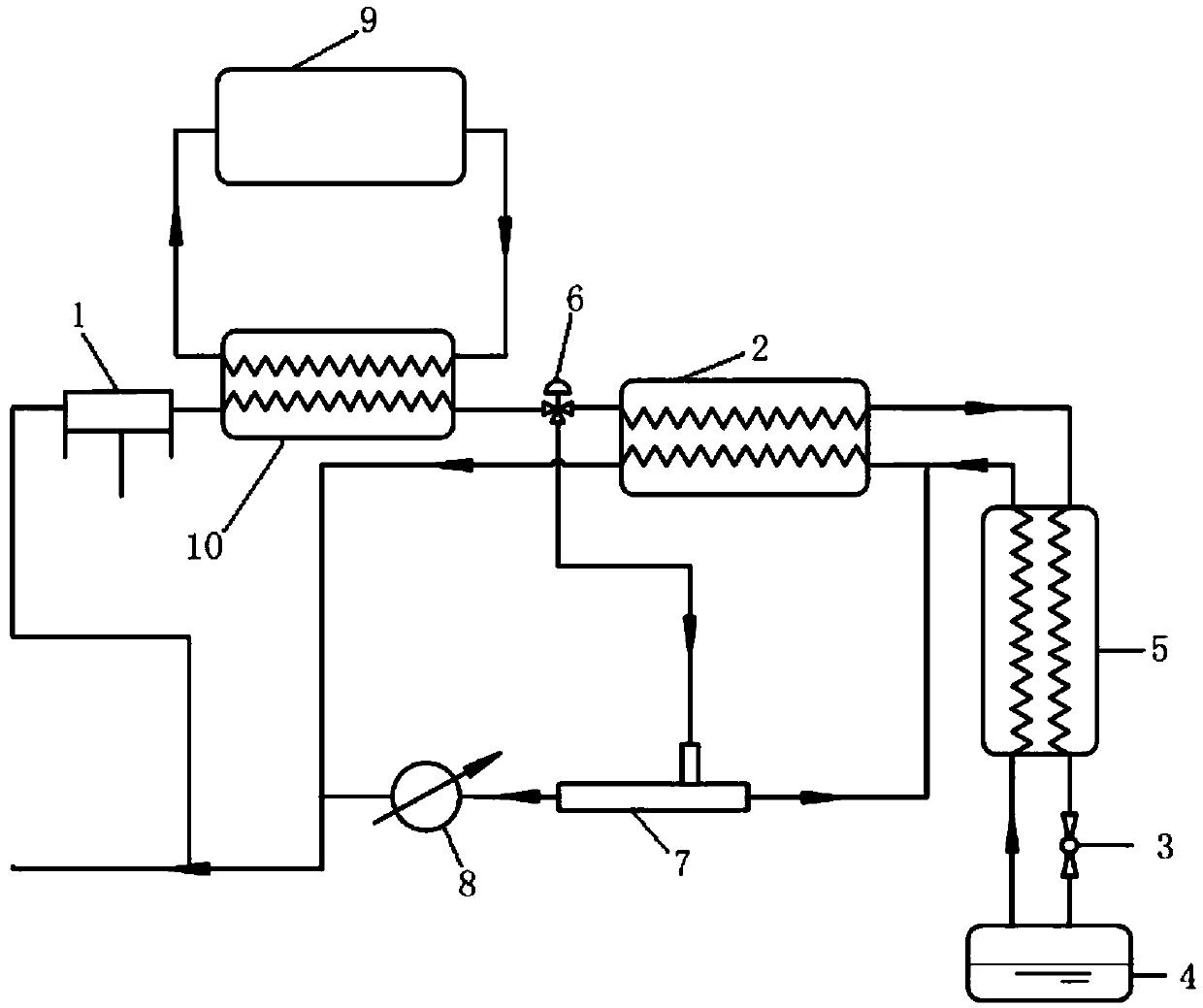

Embodiment 2

[0025] In this embodiment, on the basis of Embodiment 1, an external precooling device 9 and a third regenerator 10 are added, and the third regenerator 10 is arranged at the outlet of the compressor 1 and the inlet of the three-way flow regulating valve 6 Between, the inlet of the hot end of the third regenerator 10 is connected with the outlet of the compressor 1, the outlet of the cold end is connected with the inlet of the three-way flow regulating valve 6, and the cold end of the third regenerator 10 The inlet and the outlet of the hot end are respectively connected in series with the external precooling device 9 to form an external precooling circulation channel. This setting can perform rapid external pre-cooling on the high-pressure gas coming out of the compressor 1, so that the pre-cooling efficiency is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com