Plastic forming and processing workshop cooling water recycling system and treatment process thereof

A technology of cooling water circulation and plastic molding, which is applied in natural water treatment, non-polluted water treatment, adsorption water/sewage treatment, etc., can solve the problems of inability to purify oil stains and rust, high cooling cost of cooling water, etc., and achieve good pre-cooling effect, The effect of saving resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

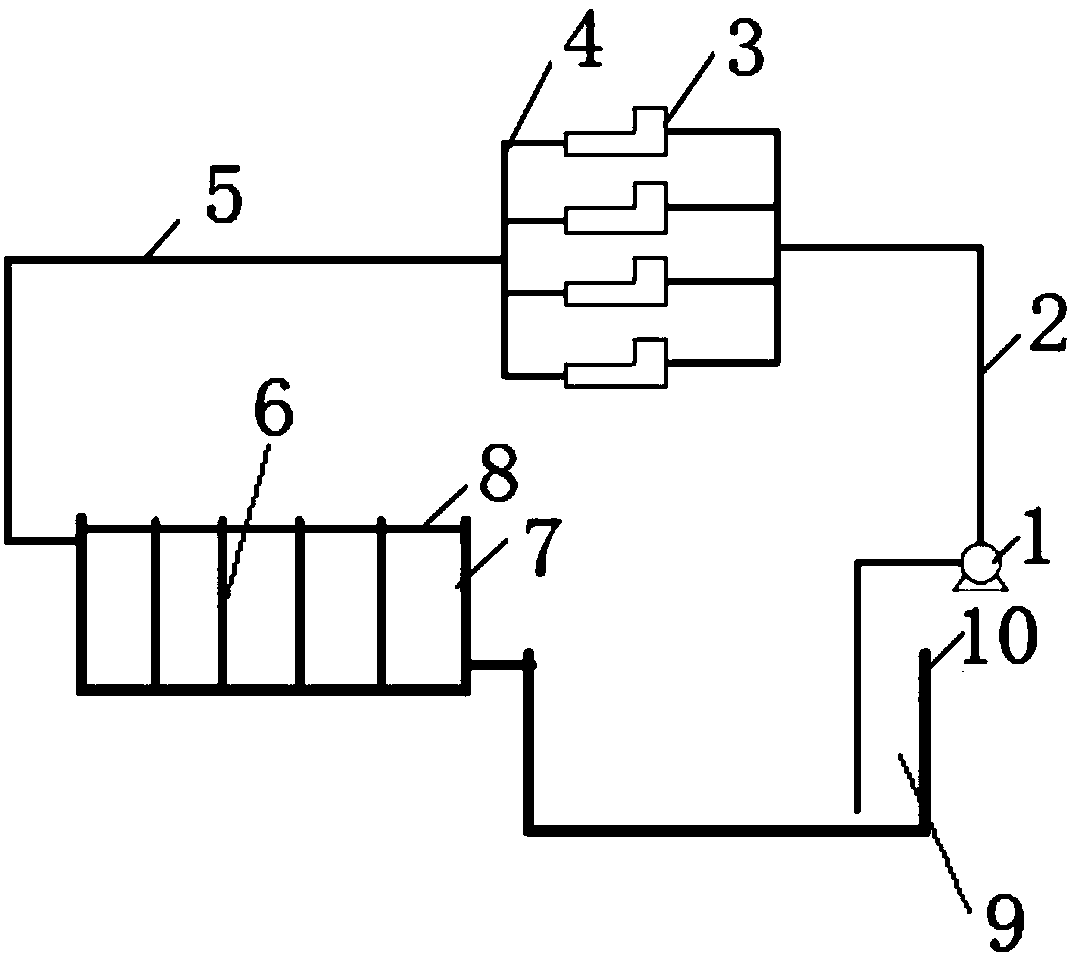

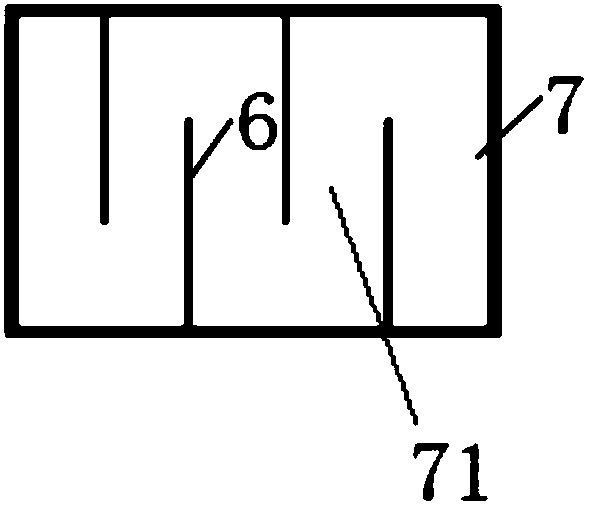

[0041] The cooling water recycling system of the plastic molding processing workshop in this embodiment includes a plastic molding processing device 3, a circulation pool 9, a water supply subsystem, a water return subsystem, and a purification subsystem; the purification subsystem includes a cooling purification pool 7, and the The cooling and purification pool 7 has a built-in circuitous tank 71 connected in sequence; wherein, the plastic molding processing device 3 has a built-in cooling water internal circulation device, the water inlet of the cooling water internal circulation device is externally connected to the water supply subsystem, and the water outlet is externally connected to the return water Subsystem, the return water subsystem communicates with the water inlet end of the cooling and purification pool 7, and the cooling and purification pool 7 outputs water to the circulation pool 9, and the circulation pool 9 is the water source of the water supply subsystem.

...

Embodiment 2

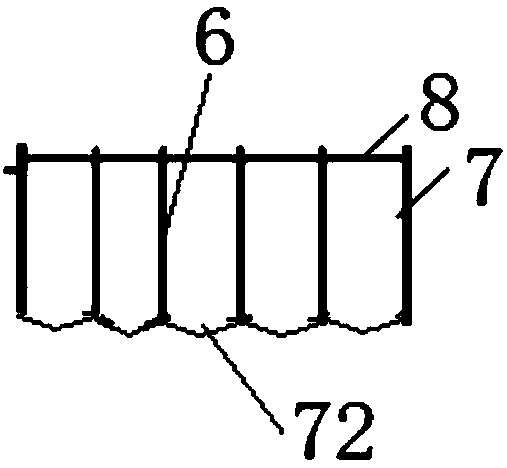

[0044] The cooling water recycling system of the plastic molding processing workshop of this embodiment has the same basic structure as that of Embodiment 1, and the improvements are as follows: figure 1 , 2 As shown, the water supply subsystem includes a water pump 1 and a water supply pipeline 2. The water pump 1 pumps the water in the circulation pool 9 into the cooling water internal circulation device through the water supply pipeline 2, specifically cooling water for injection molding and cooling and shaping water for extrusion molding. and injection molding machine, extruder feeding system cooling water; the return water subsystem includes a return water line 4, and the cooling water in the cooling water internal circulation device flows back into the cooling and purification pool 7 through the return water line 4; the cooling and purification An oil-absorbing cotton layer 8 is laid on the liquid surface of the pool 7 .

Embodiment 3

[0046] The cooling water circulation and reuse system of the plastic molding processing workshop of this embodiment has the same basic structure as that of Embodiment 2, and the improvements are as follows: figure 2 As shown, the detour tank 71 is separated by baffles 6 that are uniformly and staggered transversely fixed on the two longitudinal inner walls of the cooling purification pool 7. In this embodiment, the purification pool 7 is divided into 5 parts by 4 PVC material baffles 6 Detour slot 71 . Its function is to cool and purify the cooling water in a sufficient time, and its purpose is to increase the flow length of the return water, so that the sediment and the oil on the upper surface can be fully removed, and at the same time, the return water can flow and air. Cooling by heat exchange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com