Low-temperature double-ball spherical tank liquid distribution system and precooling method

A liquid distribution and cryogenic liquid technology, applied in the direction of gas/liquid distribution and storage, container filling method, container discharge method, etc., can solve the uneven temperature drop of the tank wall, uneven liquid distribution area, and too small liquid distribution range and other problems, to achieve the effect of increasing the liquid distribution range, reducing the stress of the tank wall, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

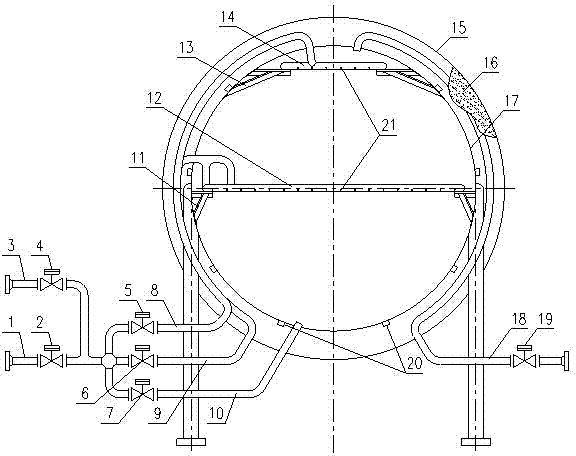

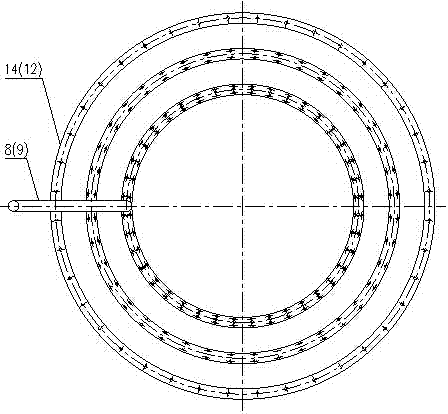

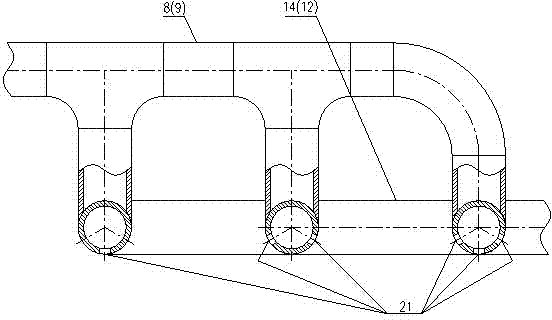

[0044] Such as figure 1 As shown, a low-temperature double-spherical tank liquid distribution system includes a liquid inlet main pipe 1, an upper liquid inlet pipe 8, a middle liquid inlet pipe 9, a lower liquid inlet pipe 10, a middle liquid distributor 12, and a top liquid distributor 14. The liquid inlet main pipe 1 is provided with a liquid inlet main pipe control valve 2, and the pre-cooling pipe 3 is connected after the valve, and the pre-cooling pipe control valve 4 is arranged on the pre-cooling pipe; Liquid pipe 8, middle liquid inlet pipe 9, and lower liquid inlet pipe 10 are respectively provided with an upper liquid inlet pipe control valve 5, a middle part liquid inlet pipe control valve 6, and a lower liquid inlet pipe control valve 7; The bottom of the spherical tank 15 is introduced along the interlayer 16 to the top of the inner spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com