An improved vacuum precooling method for low-temperature cooked meat products

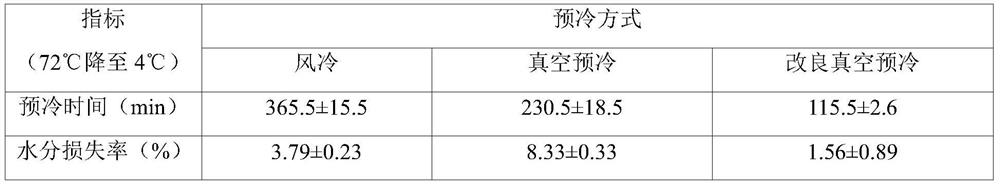

A technology of cooked meat and low temperature, which is applied in the field of vacuum pre-cooling treatment of improved low-temperature cooked meat products, which can solve the problems such as the decrease of a* value and the increase of sample L* value, so as to reduce the loss of water, reduce the loss of water and suppress water vapor Evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

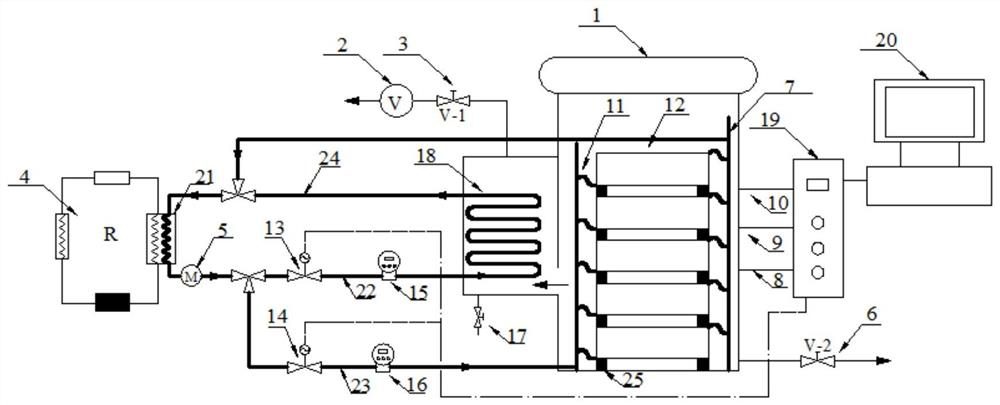

[0035] The auxiliary device group 7 involved in the present invention is used together with the vacuum precooling combination for the precooling of Western-style ham. Among them, the vacuum pre-cooler includes a condensation system, a vacuum system, a data collection system, and a data processing and operating system, which are connected in sequence, including a refrigeration unit 4, a condenser 18, a cryogenic liquid circulation pump 5, a branch pipeline I22, and an electric valve 13 , flow meter 15, branch pipe II 23, electric valve 14, flow meter 16 and hose 11, vacuum box 1, vacuum pump 2, pneumatic valve 3, exhaust valve 6, drain valve 17, weight sensor 8, pressure sensor 9 and temperature sensor 10. Data processor 19 and computer 20; the condensation system is composed of refrigeration unit 4, cryogenic liquid circulation pump 5, branch pipeline cooling capacity ①, branch pipeline cooling capacity ②; branch pipeline cooling capacity ① consists of condenser 18, branch pipe...

Embodiment 2

[0042] (1) Cook the Western-style ham so that its central temperature is 72°C, take out and remove its packaging material to obtain Western-style ham (cylindrical), the porosity of the Western-style ham is 0.38%, the diameter is 95mm, and the length is 500mm. Wrap the Western-style ham in two layers of damp gauze.

[0043] (2) Auxiliary device group 7 is first cleaned with tap water, then sterilized with 75% low-temperature alcohol, rinsed with tap water at 4±1°C for 2 minutes, and then connected to branch pipeline II23.

[0044] (3) Before vacuum precooling, turn on the refrigeration unit 4, the cryogenic liquid circulation pump 5 and the electric valves 13 and 14, and lower the temperature of the auxiliary device group 7 and the condenser 18 to the set temperature -10 through the heat exchanger 21 ±2°C.

[0045] (4) When the temperature of the auxiliary device group 7 and the condenser 18 drops to the set temperature of -10±2° C., wrap the cooked Western-style ham with ster...

Embodiment 3

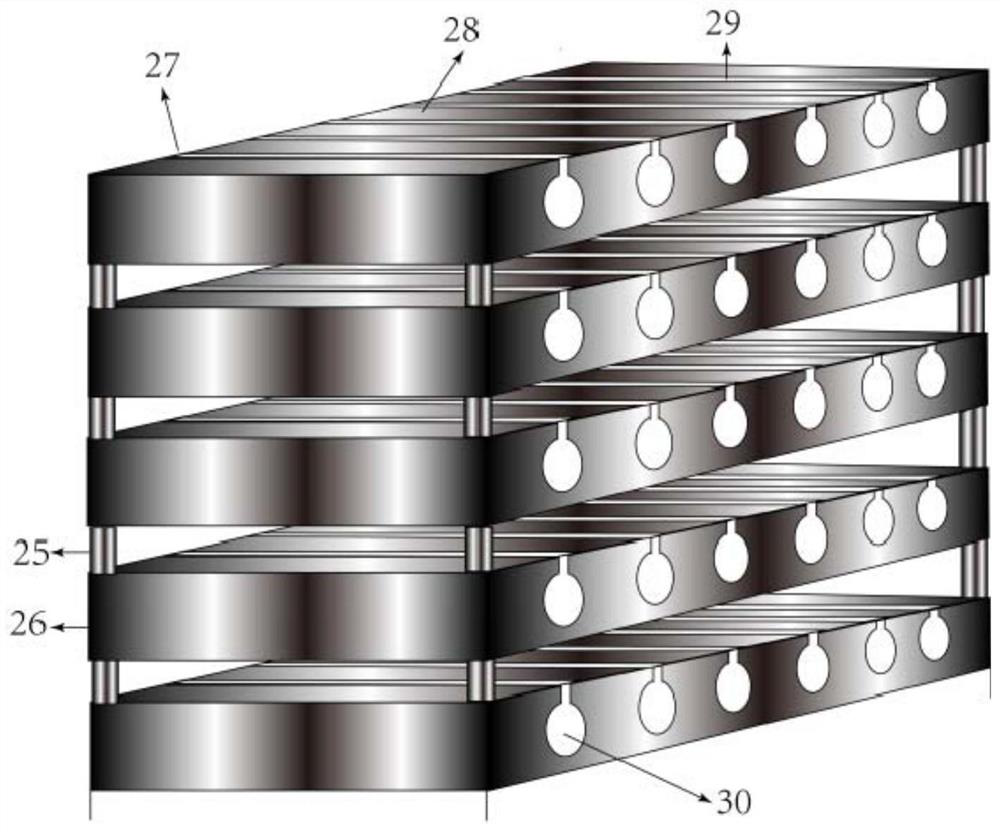

[0062]Cook the prepared ham sausage (porosity 0.86%, diameter 55mm, height 500mm) so that the center temperature is 72°C, take out and remove the packaging material, and then wrap the Western-style ham with two layers of sterilized wet gauze. Other modes of operation are as in Example 1. The device parameters designed in embodiment 3 are as follows: Western-style ham has a diameter of 55mm and a height of 500mm; the diameter of the hollow cylinder 30 is 60mm, and the height of the hollow cylinder is 500mm; the height of the hollow cuboid 26 is 90mm, the width is 500mm, and the length is 540mm (Place 6 Western-style hams); the height of the built-in small cuboid groove 27 is 15mm, the width is 3mm, and the length is 500mm; the distance between the hollow cylinders 30 on the hollow cuboid is 30mm, and the distance between the upper and lower planes of the hollow cuboid 26 is 15mm respectively . Among them, the flow diversion control of the branch pipelines I22 and II23 is imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com