Roots blower slaughtering production line

A Roots blower and production line technology, applied in slaughtering, poultry processing, food science and other directions, can solve the problems of difficulty in meeting air volume, increased cost, short service life of vortex air pumps, etc., to reduce equipment maintenance, reduce power consumption and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

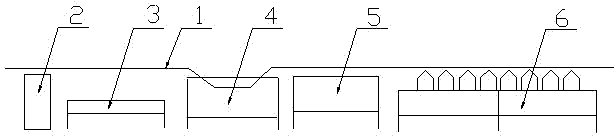

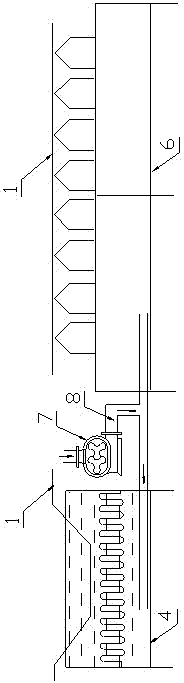

[0022] Embodiment 1: as figure 1 As shown, the Roots blower slaughter production line includes a hanging conveyor line 1, and the hanging conveyor line 1 is successively provided with an electric anesthesia machine 2, a bloodletting tank 3, a poultry scalding pool 4, a hair removal machine 5, and a spiral precooler 6, such as figure 2 As shown, the Roots blower 7 passes into the poultry scalding pond 4 bottom and the spiral precooler 6 bottom through the air outlet pipe 8 .

Embodiment 2

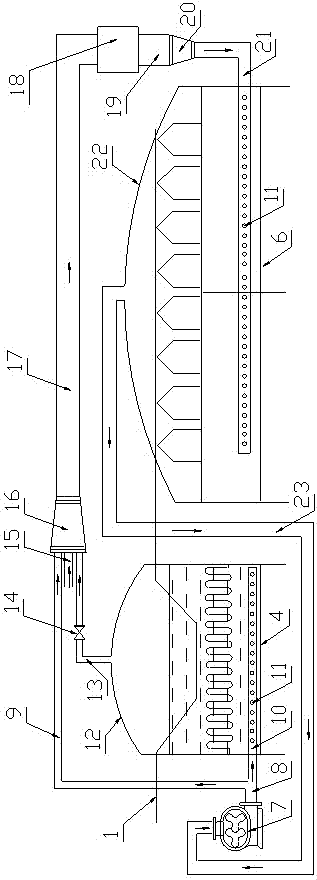

[0024] like figure 1 As shown, the Roots blower slaughter production line includes a suspension conveyor line 1, and the suspension conveyor line 1 is successively provided with an electric hemp machine 2, a bloodletting tank 3, a poultry scalding pool 4, a hair removal machine 5, and a spiral precooler 6; image 3 As shown, the air outlet of the Roots blower 7 is connected with the air outlet pipe 8, and the air outlet pipe 8 is divided into a first air pipe 9 and a second air pipe 10, and the second air pipe 10 leads into the poultry scalding pool 4 bottoms, The second air duct 10 at the bottom of the poultry scalding pond 4 is provided with some air holes 11; 13, the third air pipe 13 is provided with a check valve 14 to prevent gas backflow, and the first air pipe 9, the third air pipe 13 and the fourth air pipe 15 are all connected to the intake end of the first reducing joint 16 , the fourth air pipe 15 is also connected with the outside world, the outlet end of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com