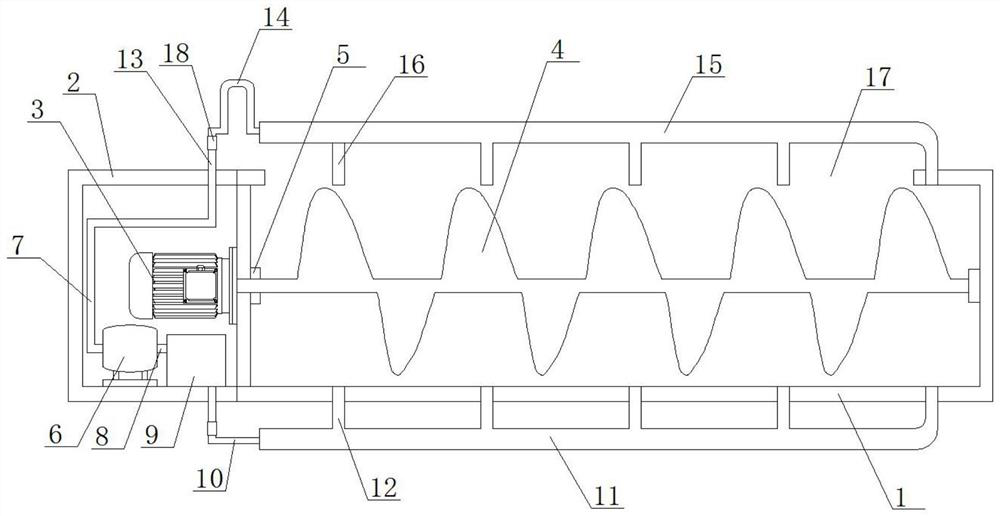

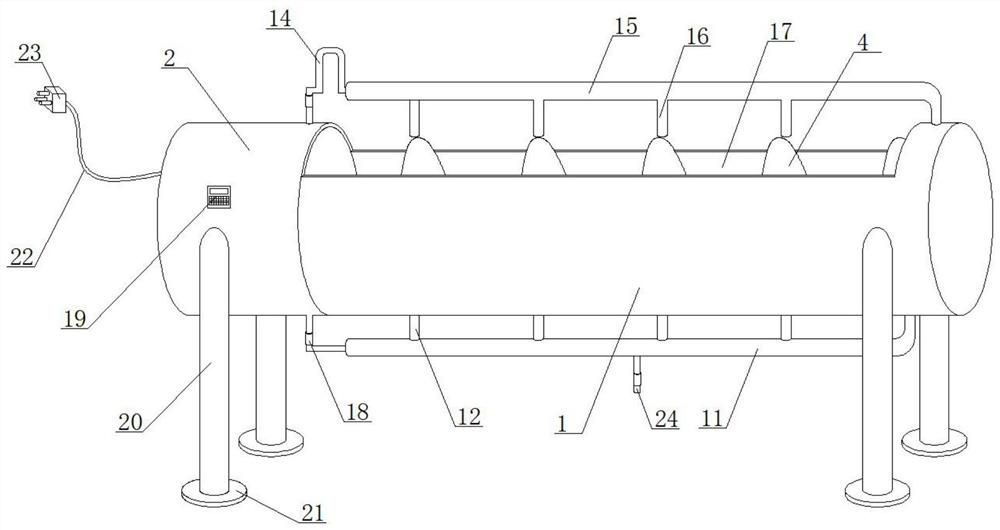

Spiral pre-cooling trough used for goose processing

A spiral, pre-cooling technology, applied in the processing of meat, poultry processing, household refrigeration devices, etc., can solve the problems of reducing the efficiency and effect of pre-cooling, uneven pre-cooling, water temperature difference, etc., to improve the contact time and cooling water. Even, enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] As a preferred embodiment of the present invention, one end of the return air pipe 15 is fixedly connected and communicated with the top of the other end of the cooling tank 1, and one end of the mixing cooling pipe 11 is fixedly connected and communicated with the bottom of the other end of the cooling tank 1. .

[0021] As a preferred embodiment of the present invention, the bottom of the cooling tank 1 is fixedly connected with support legs 20 , and the bottom of the support legs 20 is fixedly equipped with support pads 21 , and the number of the support legs 20 is four.

[0022] As a preferred embodiment of the present invention, an electric valve 18 is installed on the drain pipe 24, the output pipe 10 and the connecting pipe 13, an operation button 19 is installed on the front side of the cooling tank 1, and the motor box 2 A processor is installed inside, the rear side of the cooling tank 1 is fixedly connected with a power cord 22, and one end of the power cord ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com