Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

A technology of thin-walled parts and special-shaped curved surfaces, which is applied in the field of sheet metal and welding processing, can solve the problems of limited shape of parts, high process and high cost, achieve small deformation after welding, reduce thermal processing process and time, and high surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

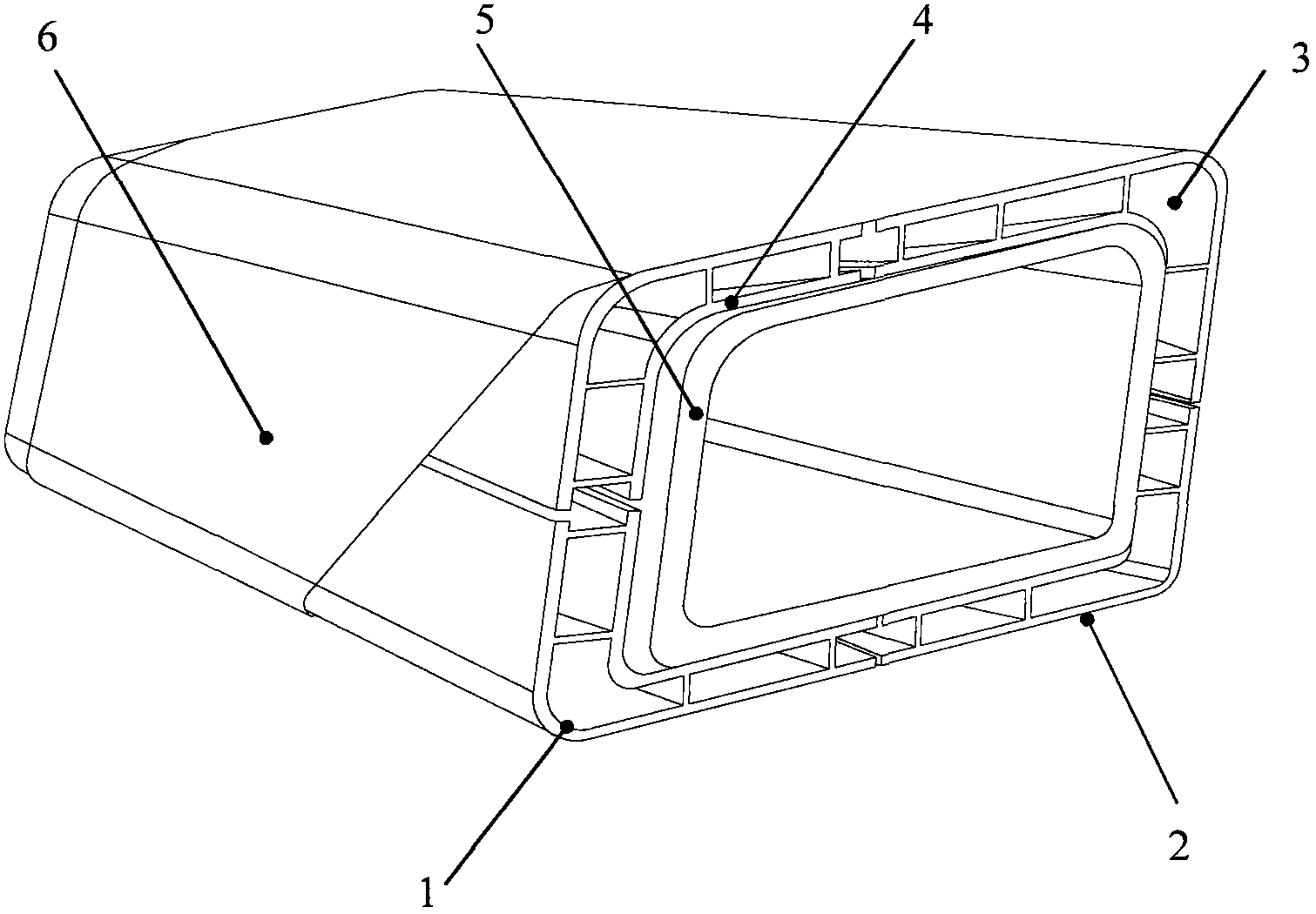

[0026] A method for integral forming of thin-walled titanium alloy parts with special-shaped curved surfaces provided by the present invention will be introduced below in conjunction with the accompanying drawings and embodiments:

[0027] A method for integrally forming a titanium alloy thin-walled part with a special-shaped curved surface, comprising the following steps:

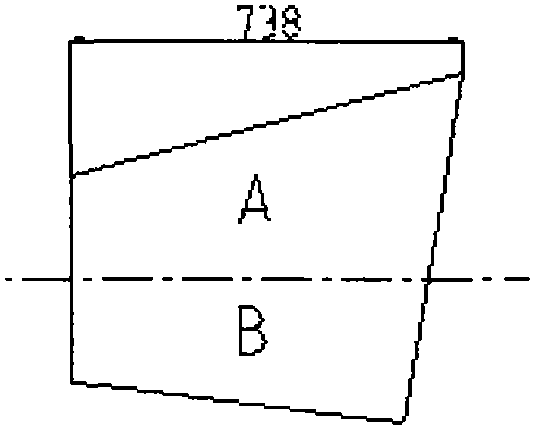

[0028] The first step is to determine the parting surface: determine the parting surface according to the shape and size of the part to be processed, divide the part into two parts, and determine the assembly welding part, and the assembly welding part can be avoided at the corner;

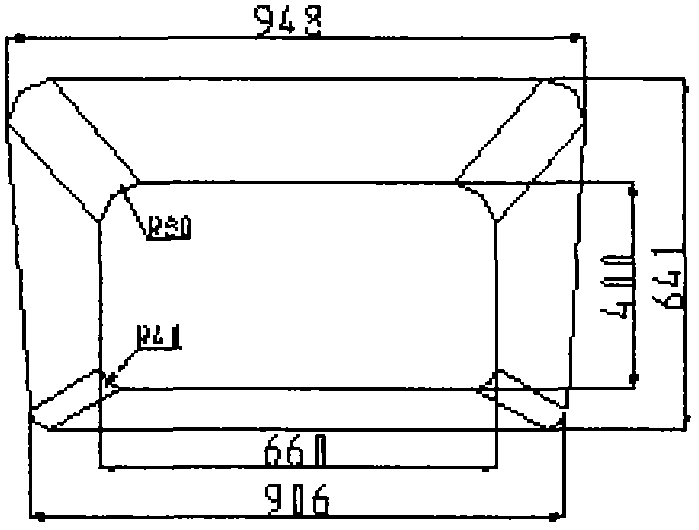

[0029] The second step of unloading: Calculate the expanded size of the two parts, use CNC punching or laser cutting to cut off the components, and remove the burrs;

[0030] The third step of pre-forming: bending the plate from a flat state into an arc through a bending die or a bending machine;

[0031] The fourth step of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com