Metal damper and design method thereof

A technology of metal dampers and dampers, which is applied in bridge construction, bridge parts, bridges, etc., can solve the problems of poor lateral deformation capacity and fatigue resistance of dampers, which affect design and use, and achieve strong design and use Convenience, flexibility, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

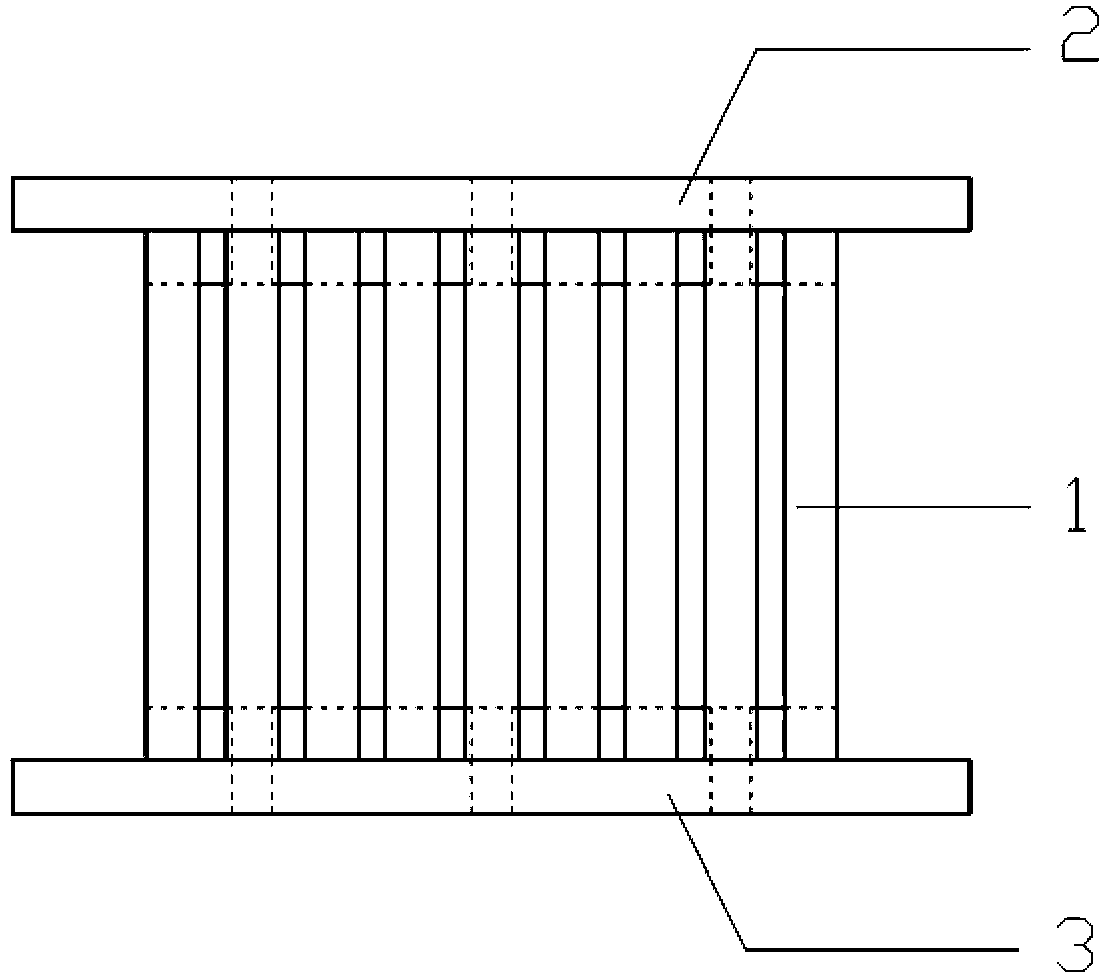

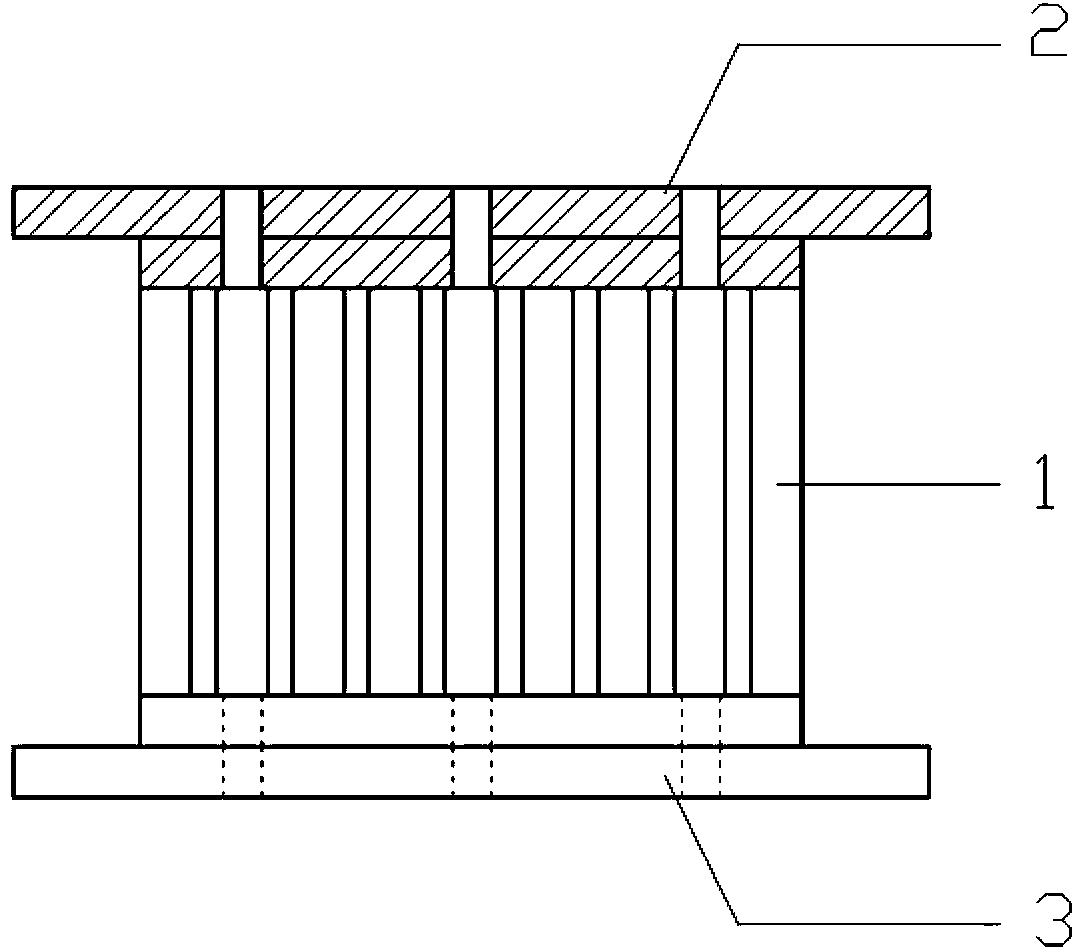

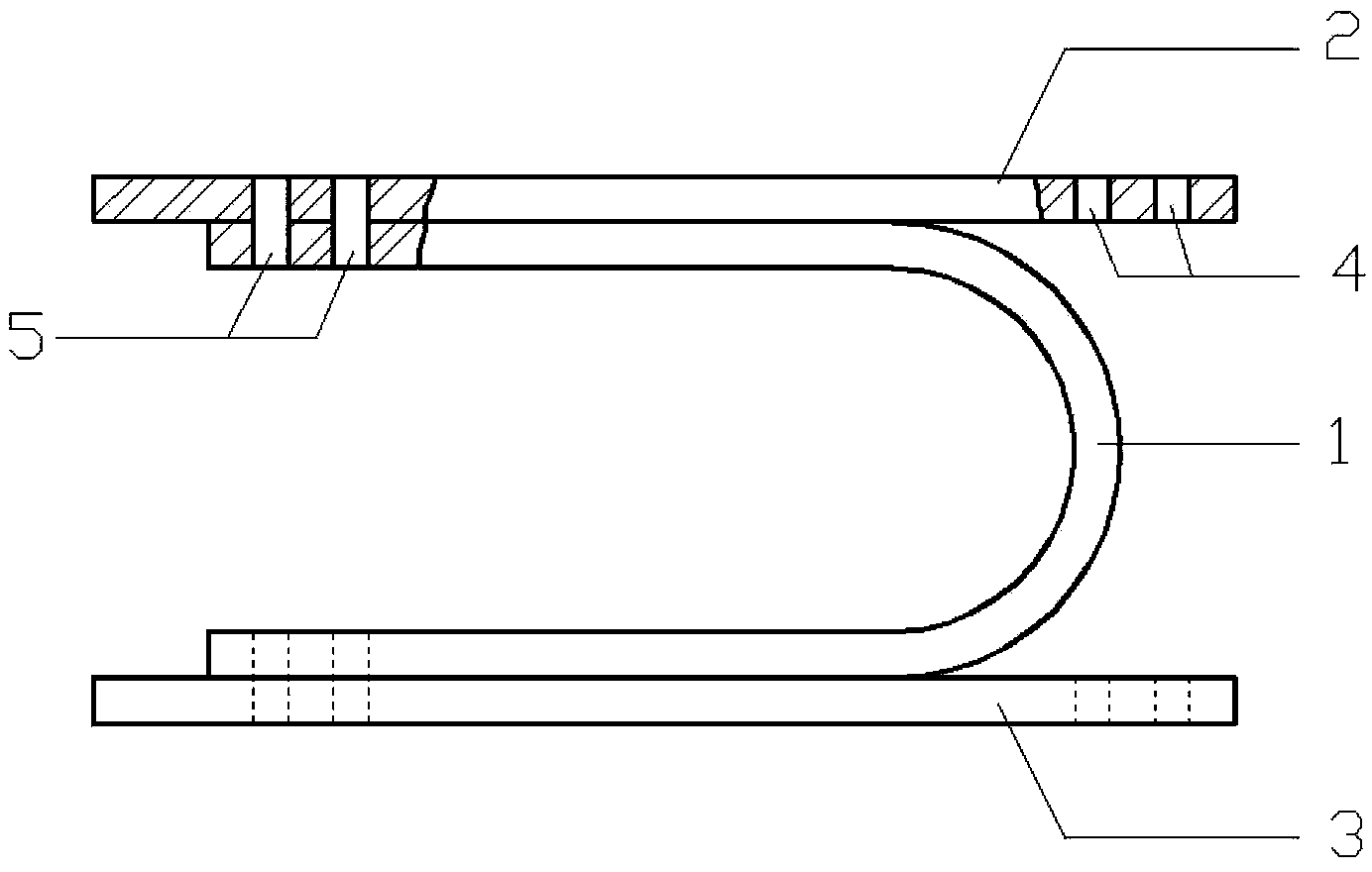

[0040] Such as figure 1 , figure 2 , image 3 The metal damper shown includes a core metal energy dissipation element, an upper cover plate 2 and a lower cover plate 3. The core metal energy dissipation element is a continuous U-shaped slotted metal plate 1 that is bent and deformed by rolling.

[0041] Such as Figure 4 and Figure 5 As shown, the slotted metal plate 1 is composed of an arc segment 6 and a straight segment 7, and a part of the arc segment 6 and the straight segment 7 are continuously slotted at equal intervals along the width direction; the ungrooved part of the straight segment 7 is provided with bolts hole; such as Figure 6 As shown, the through hole 5 at one end of the upper and lower cover plates is fixedly connected with the slotted metal plate 1 and the building structure at the same time, and the bolt hole 4 opened at the other end is only fixedly connected with the building structure.

[0042] During installation, the slotting direction of the ...

Embodiment 2

[0057] Such as Figure 9 and Figure 10 As shown, this example is similar to the first example, except that the arrangement direction of the metal dampers in this example is perpendicular to that in the first example.

[0058] In fact, the performance of the metal damper is quite stable in all directions. In actual installation, it can be installed arbitrarily according to the requirements of various building structures, and the installation direction can be flexibly designed.

Embodiment 3

[0060] When used for energy dissipation and shock absorption of bridge structures, such as Figure 11 , Figure 12 As shown, the metal damper of the present invention is placed between the bridge body and the bridge pier, and used in parallel with the bridge body support, and the threaded holes provided on the upper cover plate 2 and the lower cover plate 3 of the metal damper of the present invention are used. Fasteners (conventional technical methods, not specifically shown in the figures) connect the present invention with the bridge body and the bridge pier respectively. When connecting, the slotting direction of the metal plate can be parallel or perpendicular to the length direction of the bridge body, Figure 11 and Figure 12 Draw a schematic diagram of the installation when the slotting direction of the slotted metal plate is parallel to the length direction of the bridge body, Figure 13 and Figure 14 A schematic diagram of installation when the width of the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com