Track board deformation monitoring device and method and online monitoring system

A deformation monitoring and track plate technology, which is applied in measuring devices, optical devices, instruments, etc., can solve the problem that the displacement conversion method is not direct enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

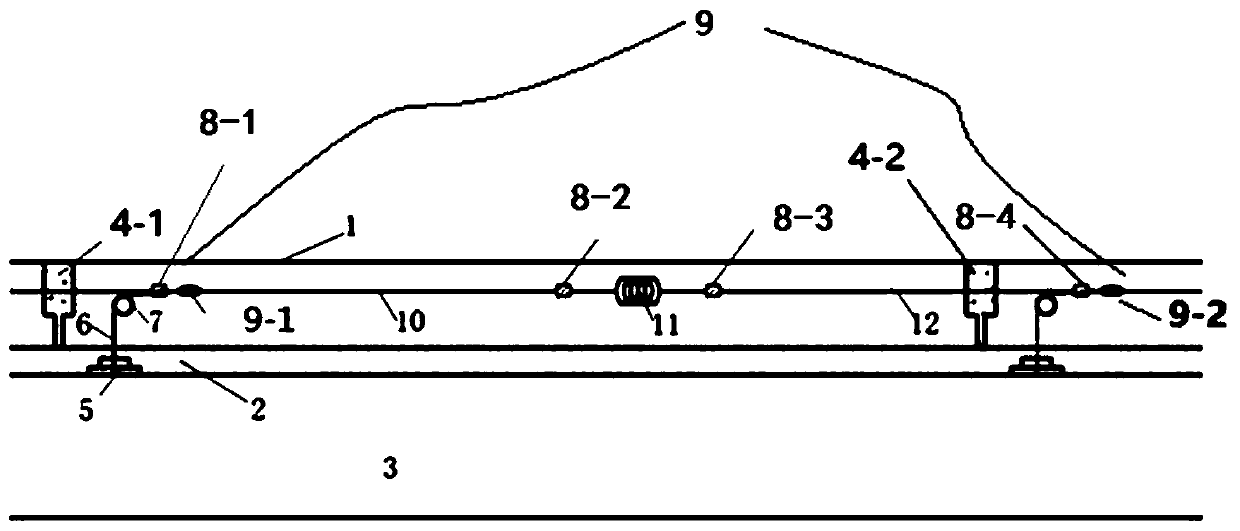

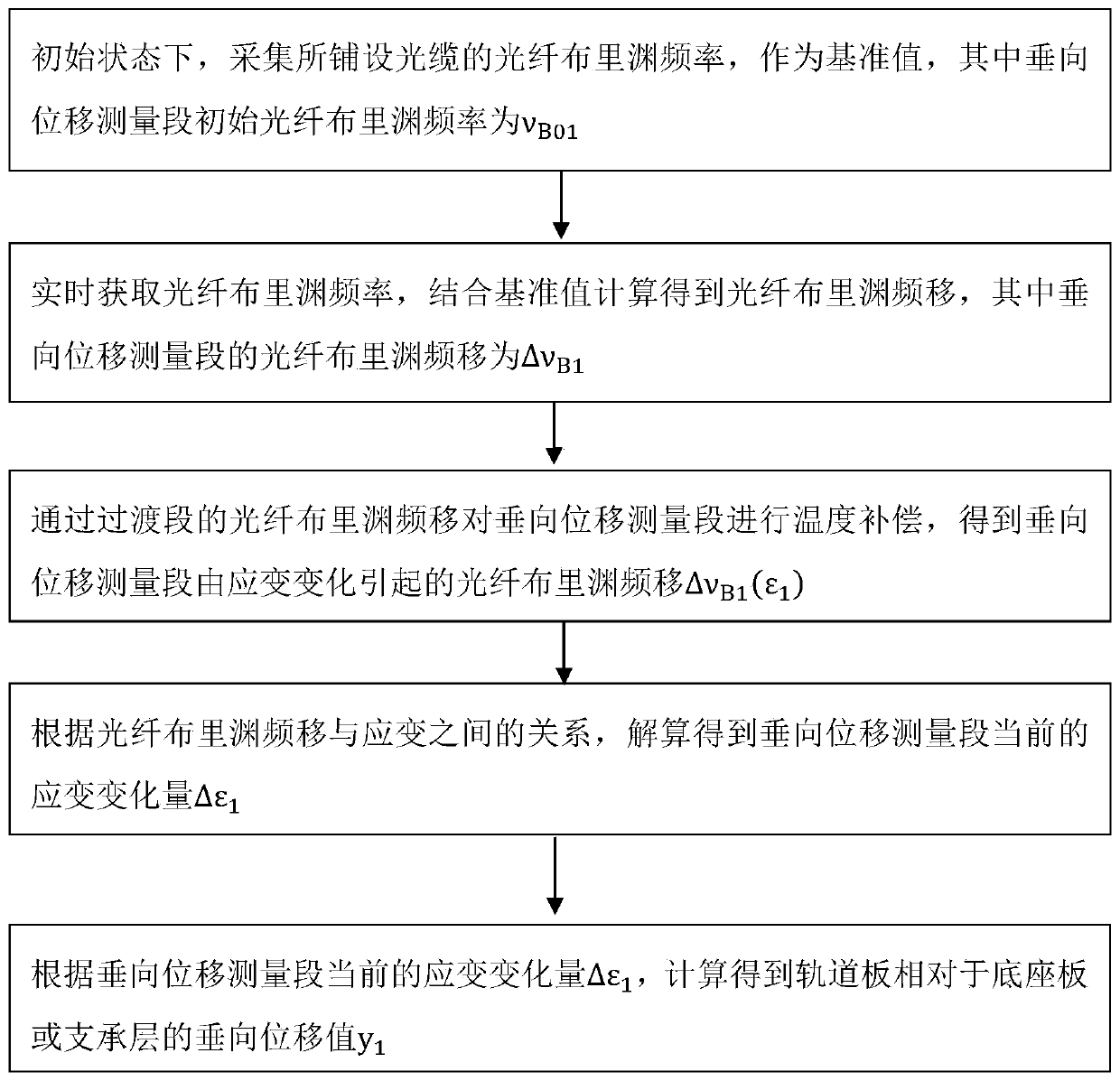

[0089] 1. Example 1 - Vertical deformation of the track plate

[0090] When the track board 1 is in continuous high temperature (eg, the weather temperature reaches 35°), that is, the current temperature of the track board 1 exceeds the preset first temperature threshold (for example, the first temperature threshold is 50°, the first temperature threshold The temperature value is not limited here) and the state duration of the current temperature is greater than the preset first time (for example, the first time is 5 to 8 hours, and the value of the first time is not specifically limited), the track plate 1 The end of the plate will be arched to produce vertical displacement, see figure 2 , the method for monitoring the deformation of the track plate includes the following steps S100-S500.

[0091] S100: in the initial state, collect the fiber Brillouin frequency of the laid optical cable as a reference value, wherein the initial fiber Brillouin frequency of the vertical dis...

Embodiment 2

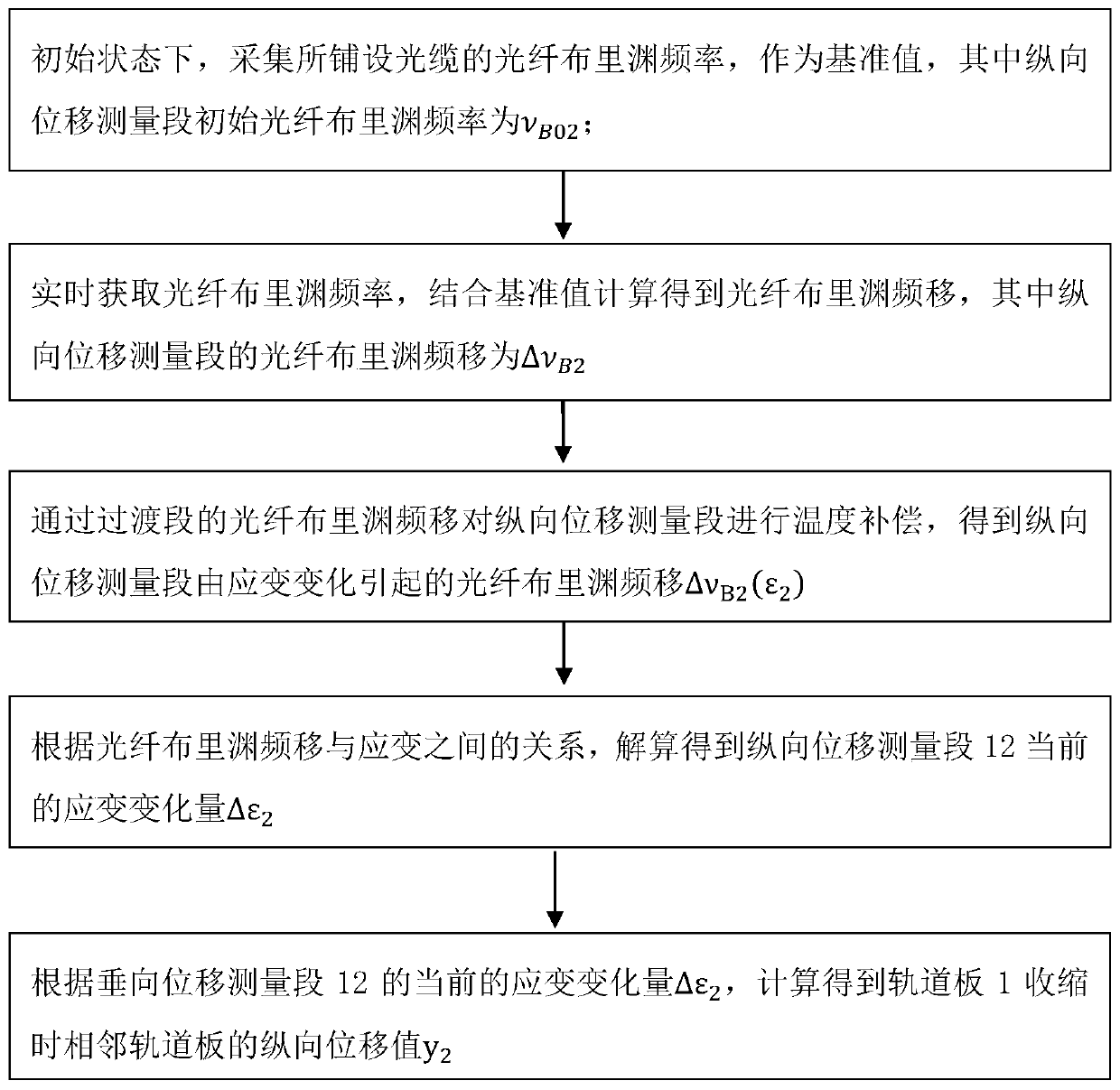

[0113] 2. Example 2 - Longitudinal deformation of the track plate

[0114] The principle and process of monitoring the longitudinal displacement of the adjacent track slabs in Embodiment 2 is roughly similar to the principle and process of monitoring the vertical displacement of the track slabs in Embodiment 1, so Embodiment 2 will be described in detail below.

[0115] When the track plate 1 is in a low temperature (for example, the weather temperature is lower than 0°), that is, the current temperature of the track plate 1 is lower than the preset second temperature threshold (for example, the second temperature threshold is 0°, the second temperature The temperature range of the threshold is not limited here) and the state duration of the current temperature is greater than the preset second time (for example, the second time is 3 to 5 hours, and the value of the second time is not specifically limited). Longitudinal displacement occurs between adjacent track plates 1, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com