Super-strength steel tie-back cable at joint for rolling ship elevator and connection structure thereof

A technology for connecting structures and lifts, applied in the field of guy ropes, can solve problems such as hidden dangers of safety, slippage of steel ropes, insufficient fixed connection force, etc., and achieve the effects of reducing maintenance, facilitating replacement, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

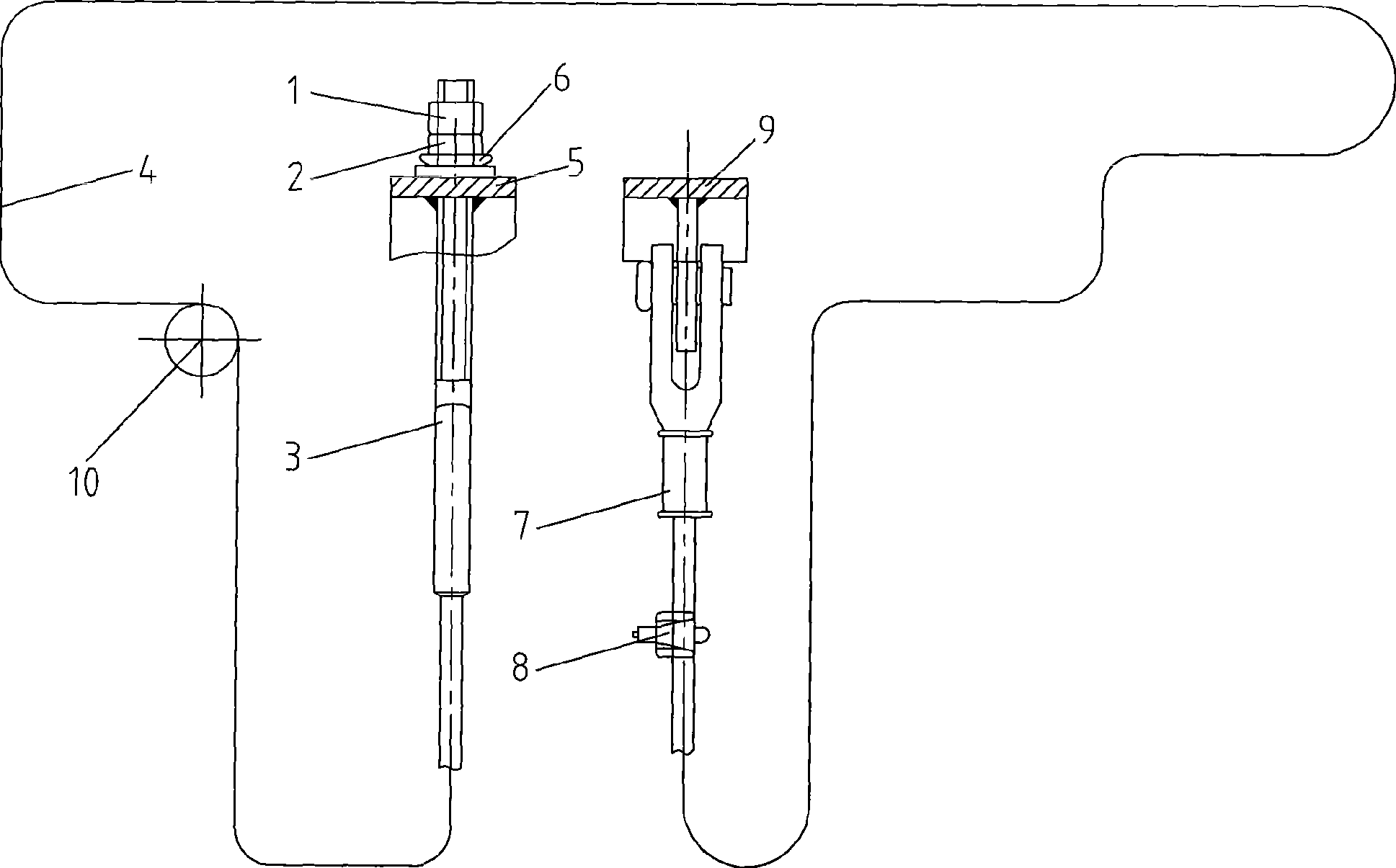

[0024] figure 1 It is a structural diagram of the super-strength steel joint cable used for the lift of the ro-ro ship of the present invention.

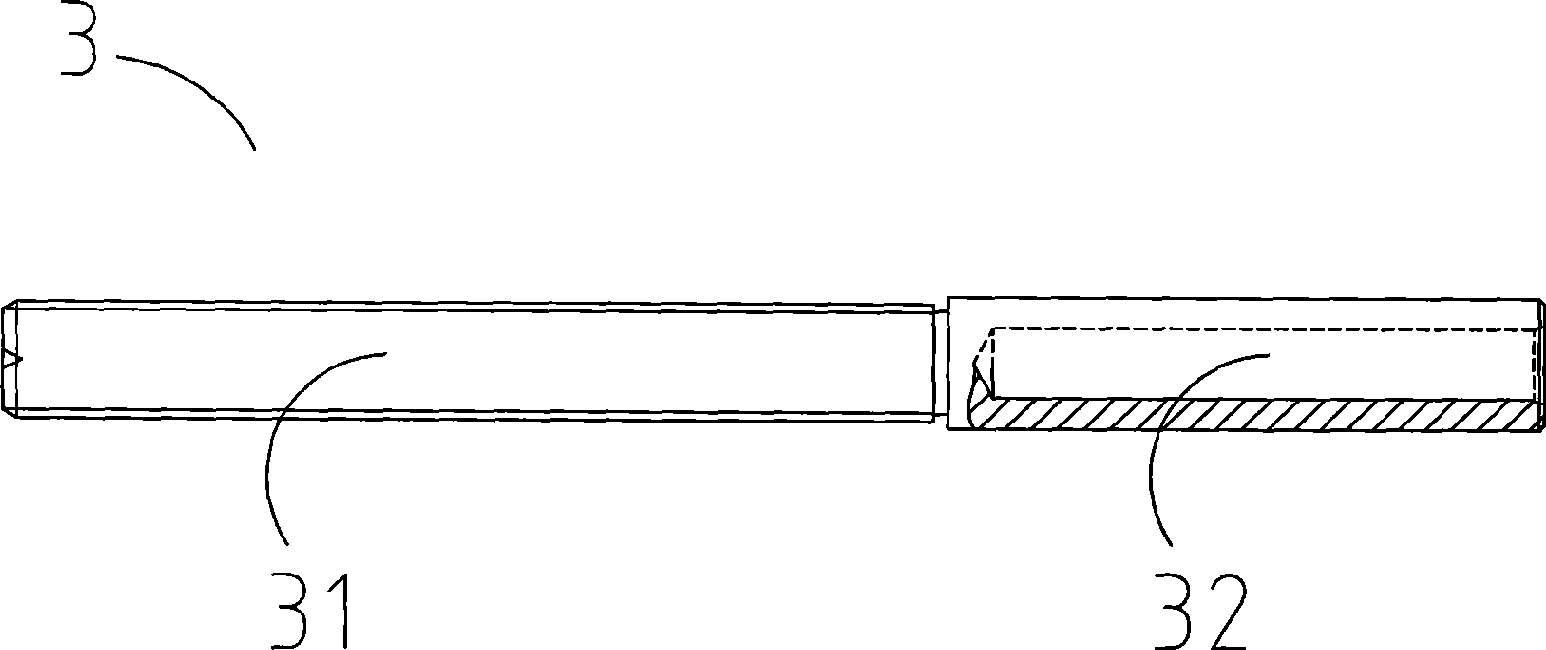

[0025] A super-strength steel joint cable for a ro-ro ship lift, including a steel wire rope 4, one end of the steel wire rope 4 is connected with a steel pressed joint 3 with a screw, and two nuts are used at the screw rod to adjust the tension of the steel wire rope. It is preferably a common hexagon nut 7, and the other is a high-strength shouldered hexagon nut 2 with a 30° angle on the end face, and the high-strength shouldered hexagon nut 2 with a 30° angle cooperates with a support seat 6. Among them, such as figure 2 As shown, the screwed steel pressed joint 3 is preferably formed by pressing an M64 screw 31, a pressed joint sleeve 32, and a steel wire rope into one body.

[0026] The other end of the wire rope 4 is connected with a wedge joint 7, and can be equipped with a wire rope rope clip 8.

[0027] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com