Ejector rod rapid modeling method for die-casting mold

A modeling method and die-casting mold technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as difficult positioning of the ejector, difficult measurement, and error-prone, to ensure accuracy and reduce repairs. Cost and effect of shortening R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

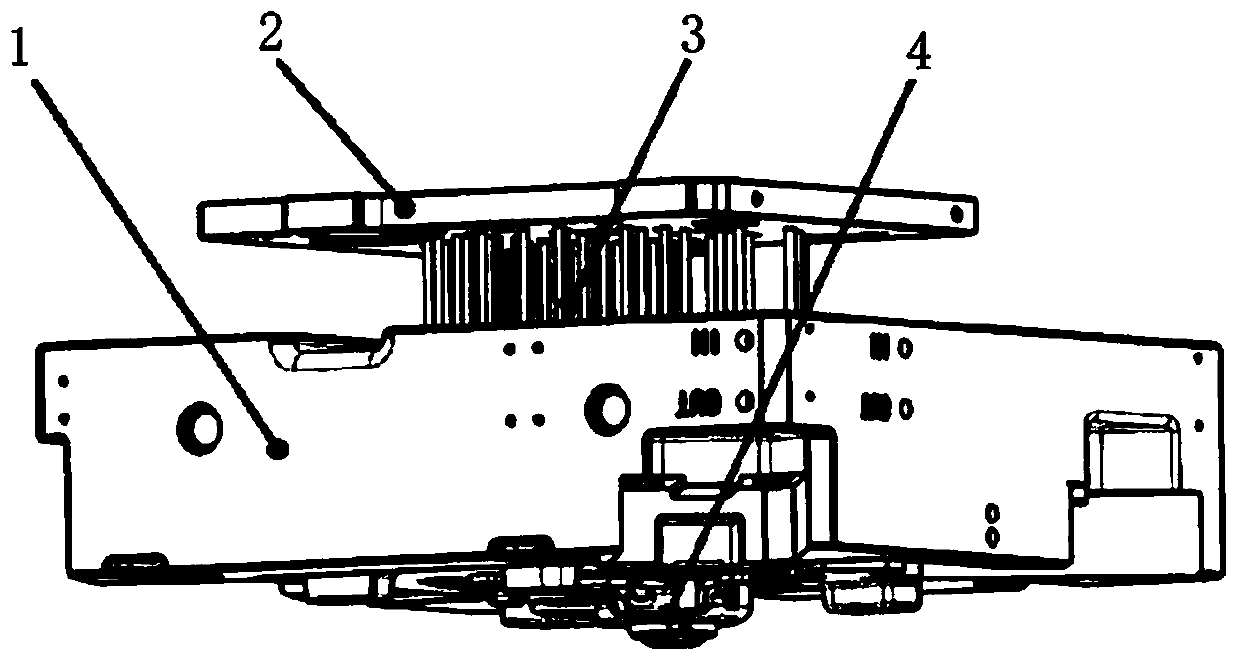

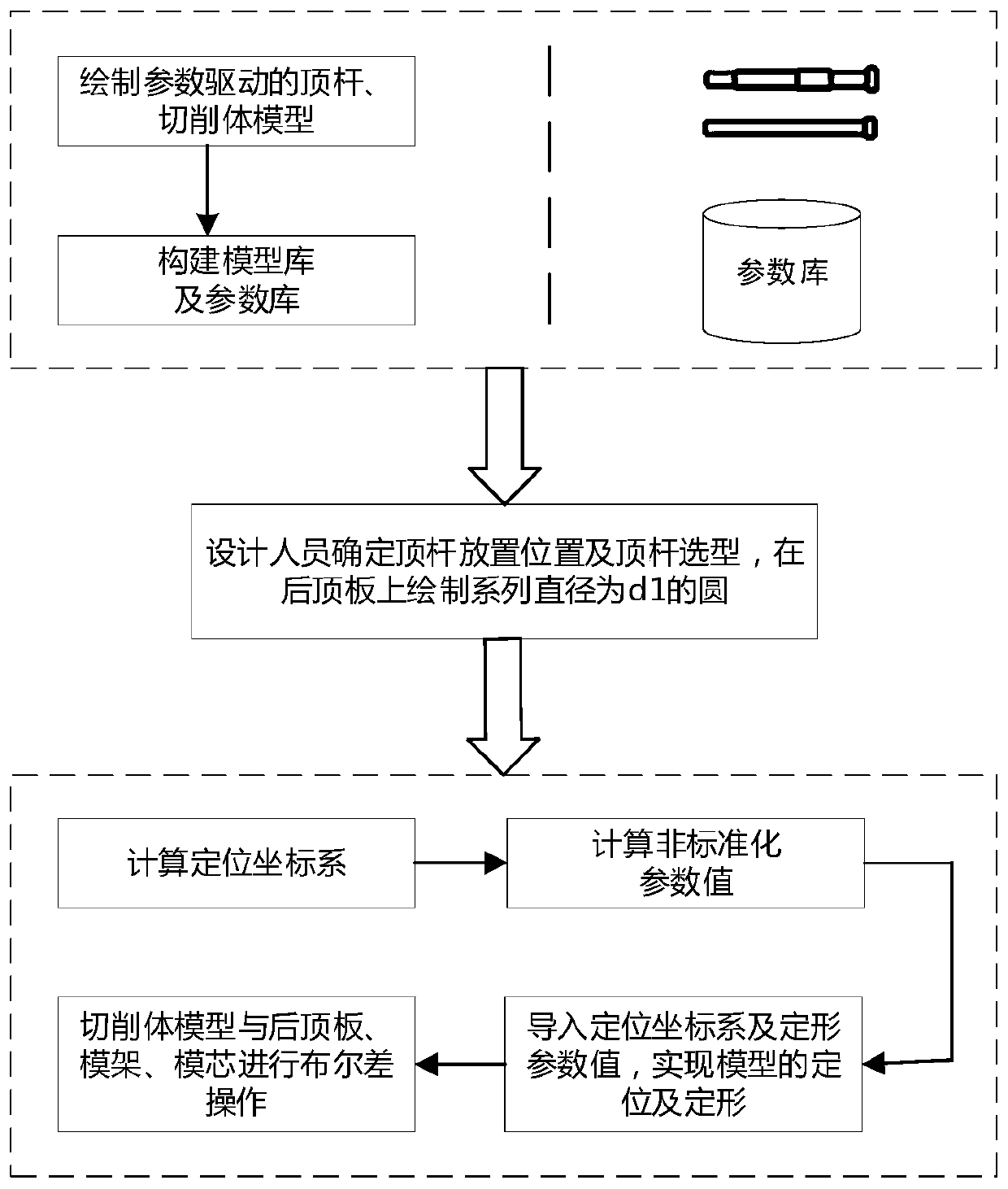

[0067] 1. Draw the three-dimensional model of ejector pin and cutting body driven by parameters

[0068] refer to Figure 5 , first draw the three-dimensional model of the ejector rod according to the position of the positioning coordinate system, and define the ejector rod parameter variable d 1 、d 2 、h 1 、h 2 , and establish the driving relationship between the parameter variables and the three-dimensional model, and complete the establishment of the parametric driven ejector model.

[0069] The three-dimensional model of the cutting body is consistent with the positioning coordinate system of the three-dimensional model of the ejector rod, and the parameter variable D of the cutting body is defined 1 、D 2 、D D 、D 5 、H 1 、H 2 、H 3 、H 4 、H 5 , establish the driving relationship between the parameter variable and the three-dimensional model, and complete the establishment of the parameterized driving cutting body model.

[0070] 2. Establish a standardized paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com