Tower crane standard section and connecting device

A technology of tower cranes and connecting devices, which is applied in the direction of cranes, rod connections, connecting components, etc., can solve the problems of high installation costs of tower crane standard sections, achieve structural safety and high installation costs, avoid loose bolts, and ensure safety Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

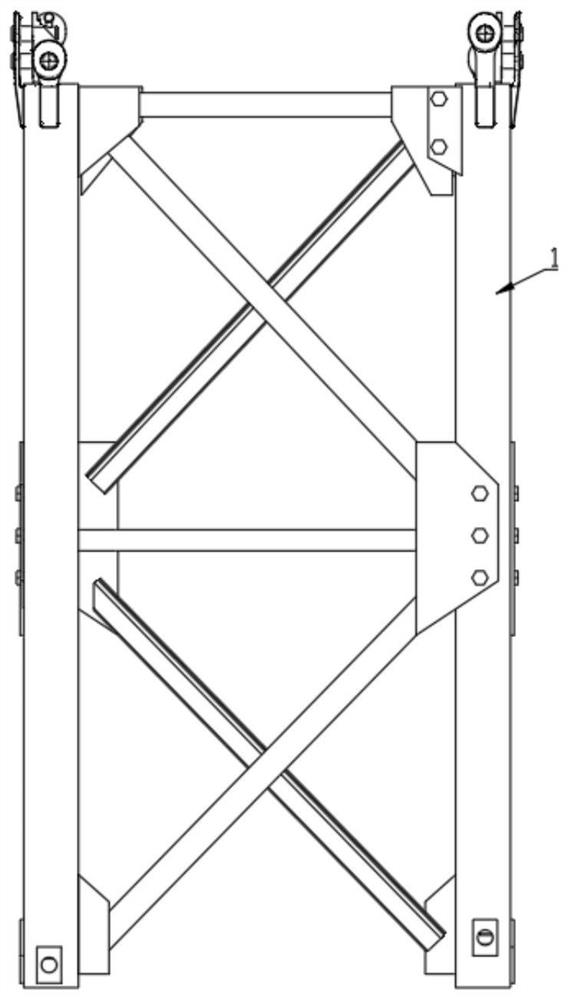

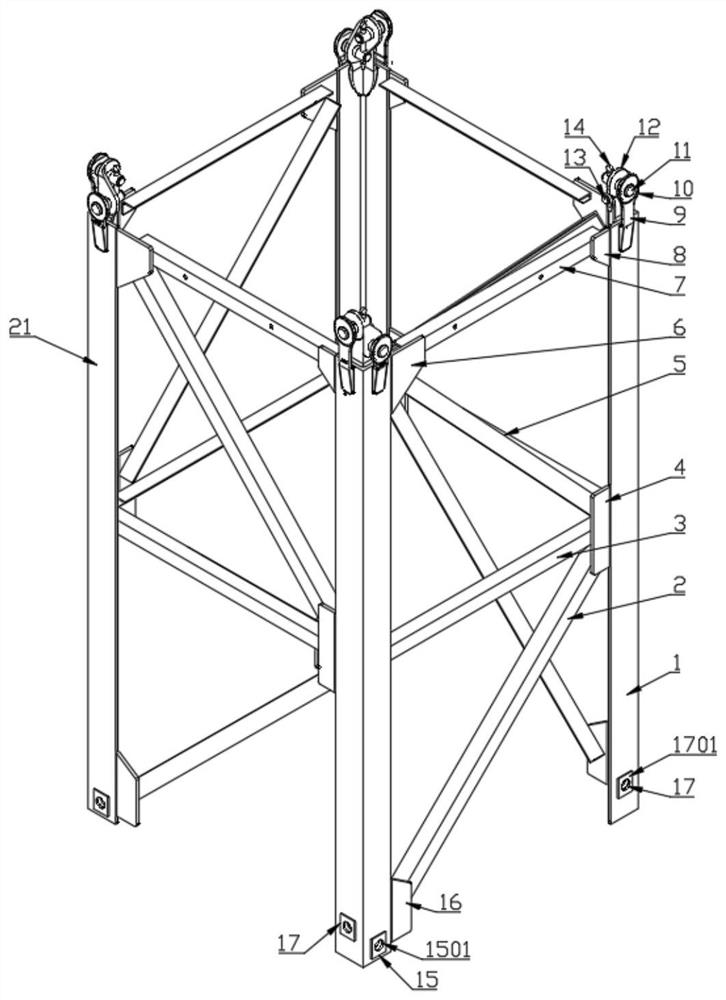

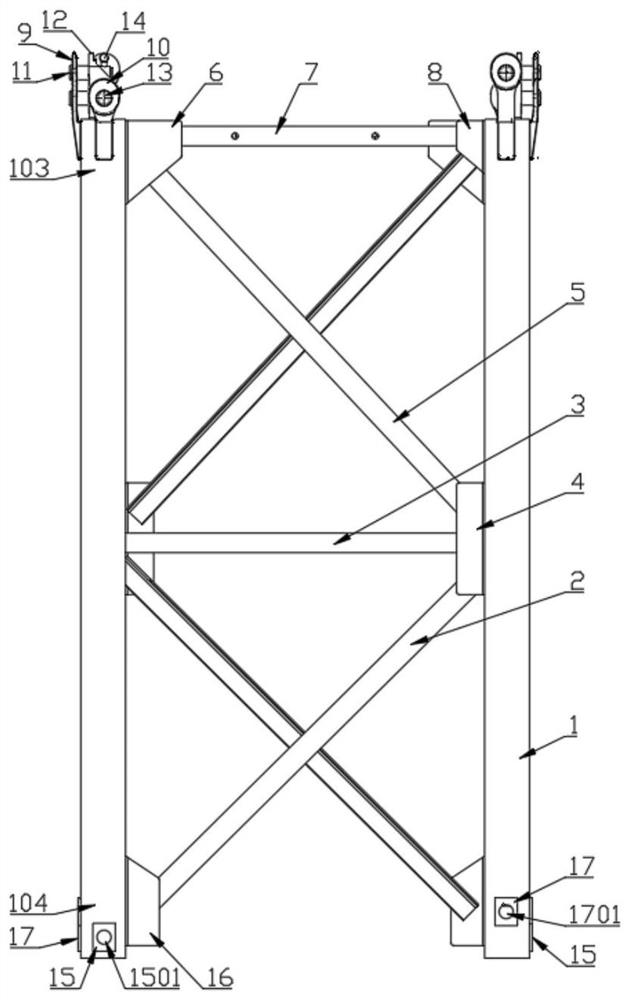

[0039] Such as Figure 2-7 As shown, in a standard section and connection device of a tower crane according to the present invention, the angle steels of the four main limb columns of the main limb column 1 are all angle steel structures with the same structural model, and the reinforcing connecting rod includes a first reinforcement Connecting rod 2, the second reinforcing connecting rod 5, described beam bar refers to or comprises first beam bar 3, second beam bar 7, and described upper connecting plate is to comprise left upper connecting plate 6, right upper connecting plate 8, so Described intermediate connecting plate comprises intermediate connecting plate 4, and described lower connecting plate comprises left lower connecting plate 6; Described pin plate comprises left lower pin plate 15 and right lower pin plate 17, has left lower pin on left lower pin plate 15. Shaft hole 1501, the lower right pin shaft plate 17 is provided with the lower right pin shaft hole 1701 as...

Embodiment 2

[0044] Except for the following descriptions, all the rest are the same as the descriptions in Embodiment 1 and the above-mentioned specific implementation manners.

[0045] Such as Figure 8 , 9 As shown, the connection structure adopted by the fixed standard section 21 of this embodiment is that the four main limb columns 1 of the angle steel structure are connected with the reinforcing connecting rod and the beam rod, and are directly fixedly connected to any adjacent two main limbs. on the inner wall corresponding to the angle steel of the column 1, or fixedly connected to the inner wall corresponding to the angle steel of any adjacent two main limb columns 1 through the upper connection plate, the middle connection plate, and the lower connection plate, and the reinforced connection The rod is in a zigzag structure and is directly or fixedly connected to the inner side walls of any adjacent two main limb columns 1 through the upper connecting plate and the lower connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com