Field management control system and method

A technology of on-site management and control system, applied in general control system, control/adjustment system, program control, etc., can solve problems such as low efficiency, inability of staff to discover in time, failure to confirm unqualified gray cloth production machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

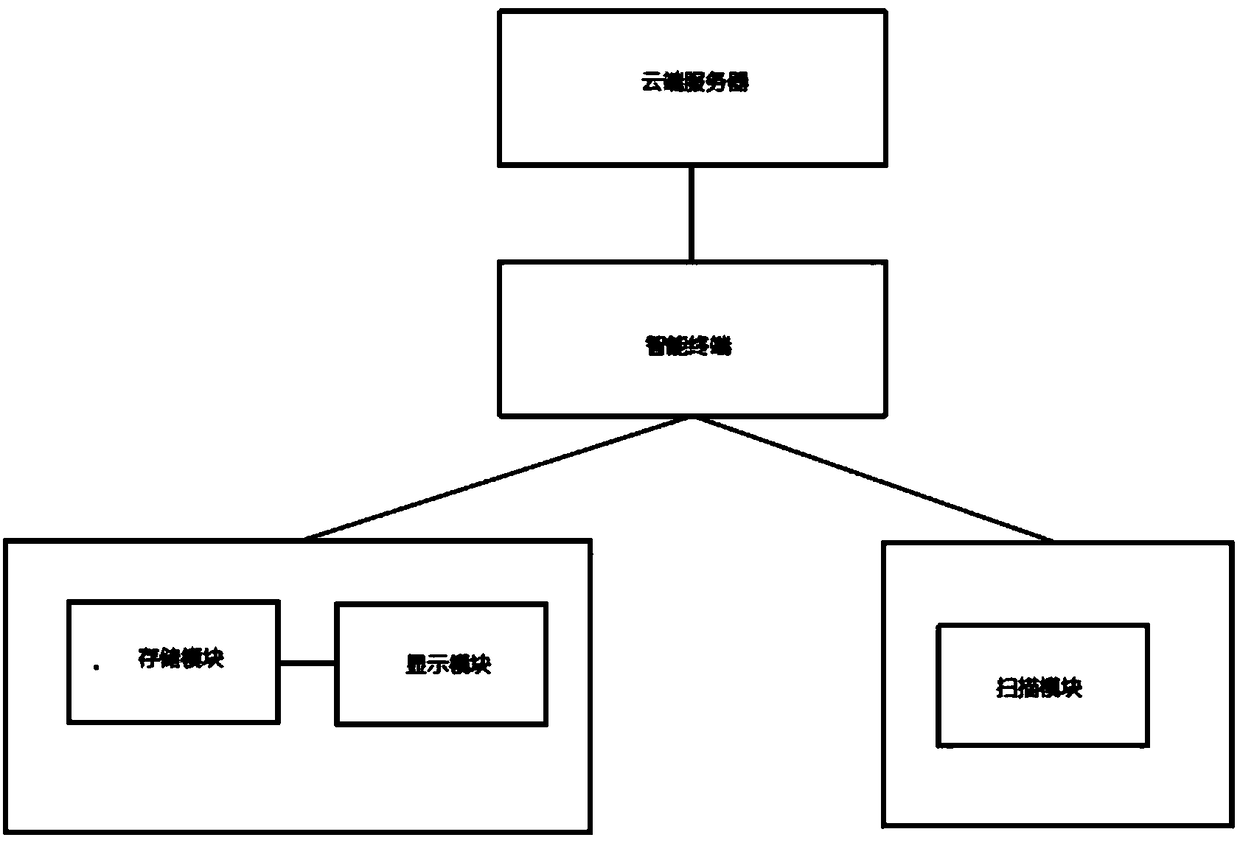

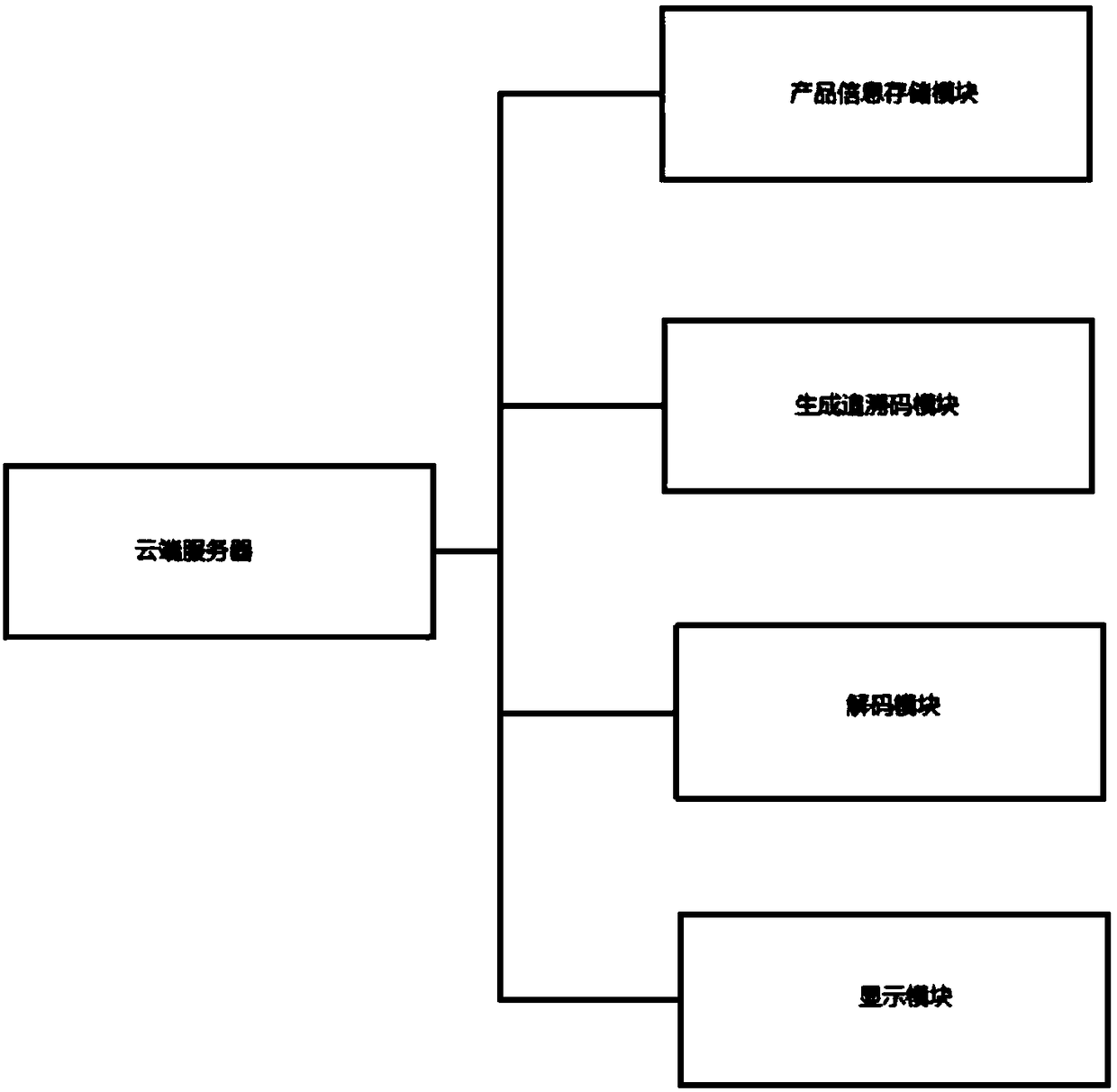

[0027] Such as Figure 1-2 As shown, an on-site management control system includes a cloud server and an intelligent terminal. The cloud server includes a product information storage module, a traceability code generation module, a transmission module, a decoding module, and a display module. The cloud server performs data connection with the intelligent terminal. The intelligent terminal includes a knitting device and a scanning device, the knitting device includes a knitting device, the knitting device is provided with a data control system, and the data control system includes a storage module, a display module, and an information transmission module, and the storage module passes through The information transmission module is interactively connected with the display module, and the display module performs data communication with the cloud server through a scanning device, the scanning device includes a scanning device, and the scanning device is provided with a scanning con...

Embodiment 2

[0036] Such as Figure 1-2As shown, an on-site management control system includes a cloud server and an intelligent terminal. The cloud server includes a product information storage module, a traceability code generation module, a transmission module, a decoding module, and a display module. The cloud server performs data connection with the intelligent terminal. The intelligent terminal includes a knitting device and a scanning device, the knitting device includes a knitting device, the knitting device is provided with a data control system, and the data control system includes a storage module, a display module, and an information transmission module, and the storage module passes through The information transmission module is interactively connected with the display module, and the display module is connected to the cloud server through a scanning device for data connection, the scanning device includes a scanning device, and the scanning device is provided with a scanning c...

Embodiment 3

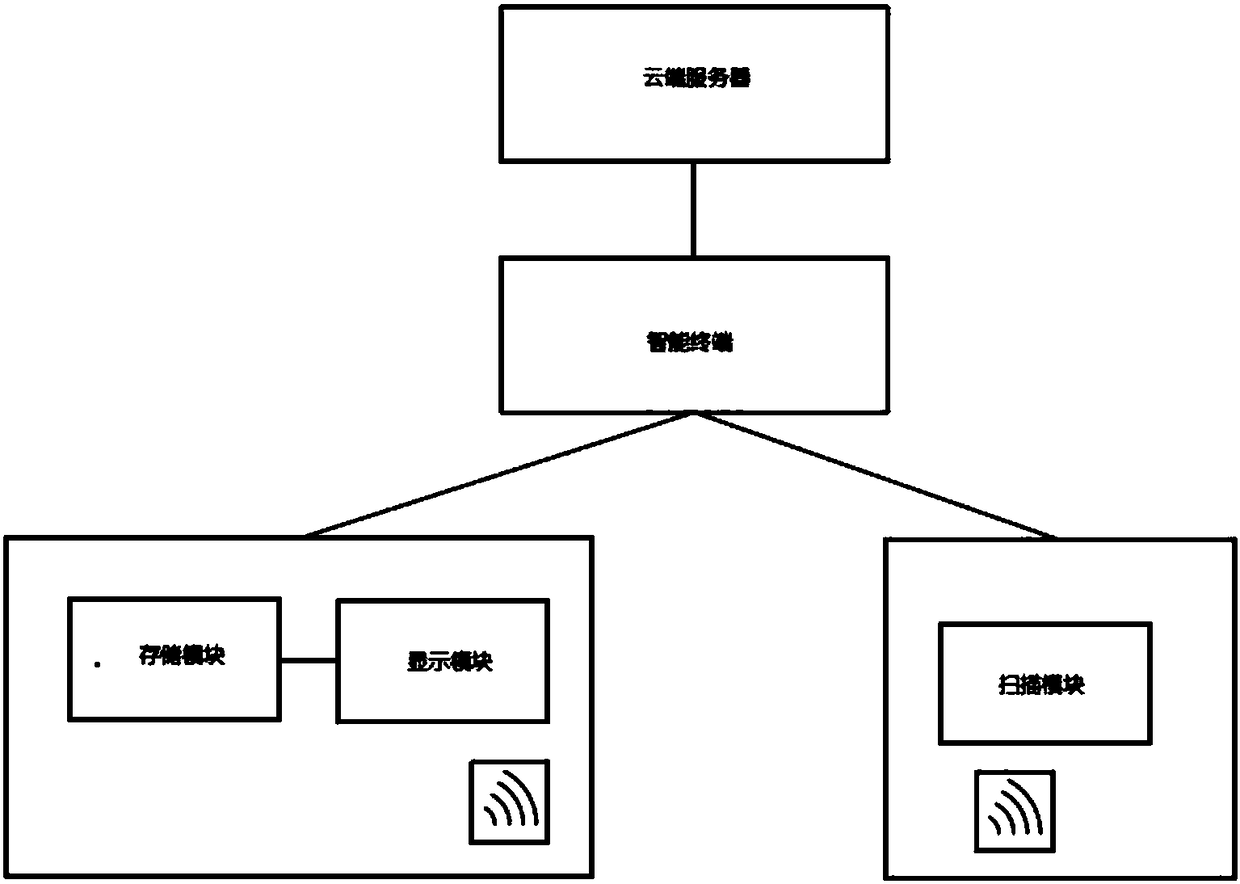

[0045] Such as Figure 2-3 As shown, an on-site management control system includes a cloud server and an intelligent terminal. The cloud server includes a product information storage module, a traceability code generation module, a transmission module, a decoding module, and a display module. The cloud server performs data connection with the intelligent terminal. The intelligent terminal needle includes a knitting device and a scanning device, the knitting device includes a knitting device, and the knitting device is provided with a data control system, and the data control system includes a storage module, a display module, and an information transmission module. The storage module The information transmission module is interactively connected with the display module, and the display module performs data communication with the cloud server through a scanning device, the scanning device includes a scanning device, and the scanning device is provided with a scanning control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com