Twin-screw compressor rotor profile

A compressor rotor and twin-screw technology, applied to mechanical equipment, machines/engines, rotary piston pumps, etc., can solve problems such as noise and vibration, difficulty in implementation, and inflection points, so as to reduce noise and vibration, reduce The effect of aerodynamic drag and small leakage triangle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

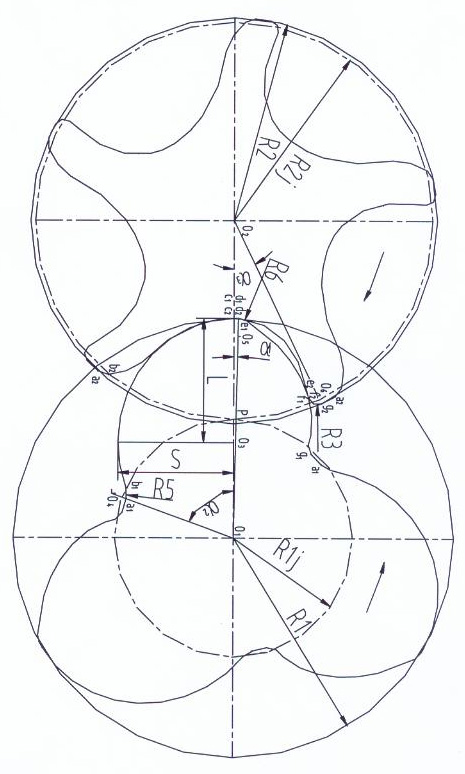

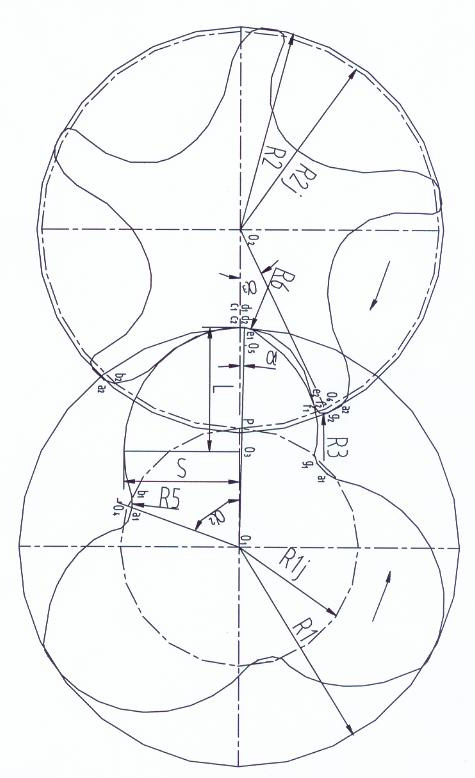

[0041] The construction of the twin-screw compressor rotor end profile of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0042] see figure 1 , The present invention provides a rotor profile of a twin-screw compressor. The profile below the center line in the figure is the profile of the active side, and the profile above the center line is the profile of the passive side.

[0043] The present invention adopts bilateral asymmetric molding lines, and the male and female rotor end surface molding lines are respectively composed of six sections of molding lines. The male and female rotor profile series of screw compressors are formed with the same center distance A and different sizes of female and male rotors. Among them, the molded line composition of the female rotor is as follows:

[0044] a 1 b 1 Segment: arc a 1 b 1 The dedendum circle of the front cut male rotor is at a 1 point, backcut ellipse arc b 1 c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com