A compression heat pump screw host helical teeth and a compression heat pump screw host

A technology of helical teeth and compression heat, which is applied in the field of helical teeth of compression heat pump screw hosts and compression heat pump screw hosts, can solve the problems of high original investment cost and failure to satisfy customers, and achieve high utilization rate of inter-gear area, small closed volume, The effect of large power and load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

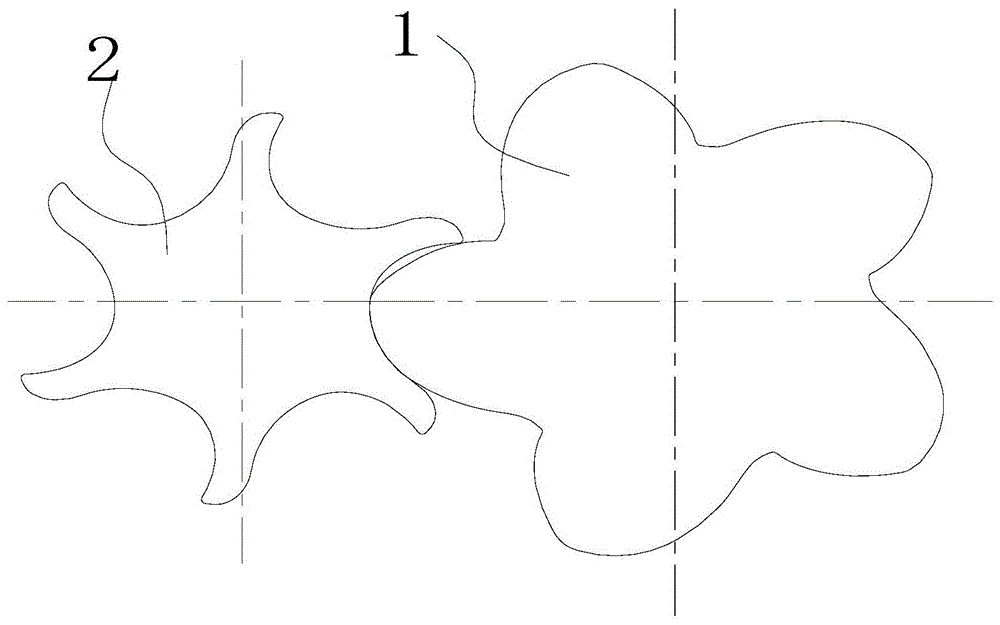

[0042] Such as figure 1 As shown, a compression heat pump screw host includes helical teeth, the helical teeth include male helical teeth 1 and female helical teeth 2, and the tooth profiles of the male helical teeth 1 and female helical teeth 2 are bilateral asymmetric helical teeth profile, the composition curve is an arc and its envelope, the number of teeth of the male helical teeth 1 is 5, the number of teeth of the female helical teeth 2 is 6, the tooth profiles of the male helical teeth 1 and the female helical teeth 2 The space design yoke clearance is 0.053mm. Considering the machining accuracy control level, the space yoke clearance of the male helical tooth 1 and the female helical tooth 2 can be relaxed to 0.04mm~0.06mm.

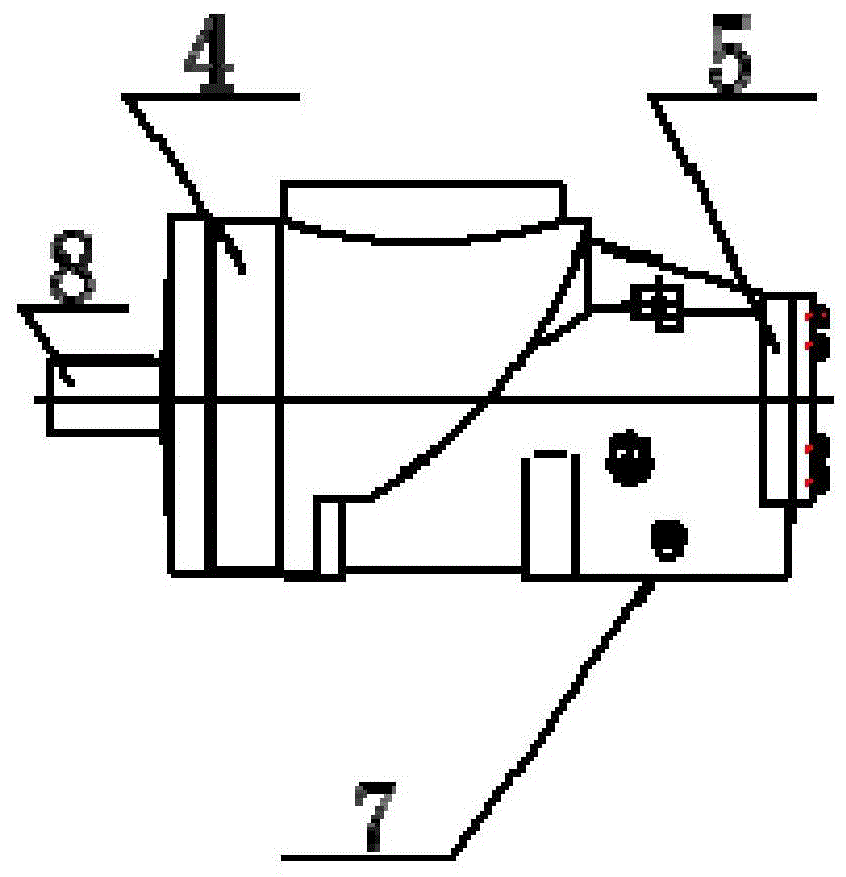

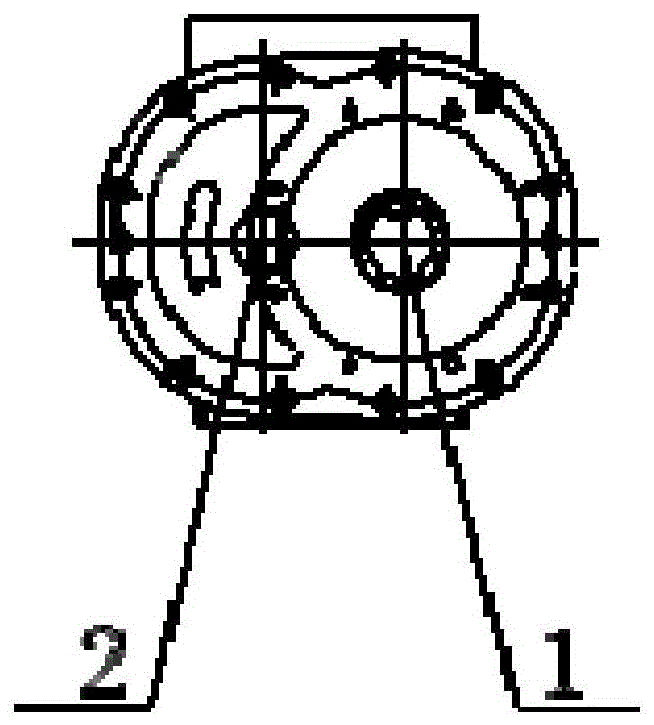

[0043] Such as Figure 2-4 As shown, the compression heat pump screw main engine of the present invention also includes a housing 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com