A fully smooth self-engaging dry screw vacuum pump and its rotor

A screw vacuum pump and rotor technology, used in rotary piston pumps, components of pumping devices for elastic fluids, rotary piston/oscillating piston pump components, etc., can solve problems such as rotor leakage of dry screw vacuum pumps , to achieve the effect of short contact line, large inter-tooth area and high volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

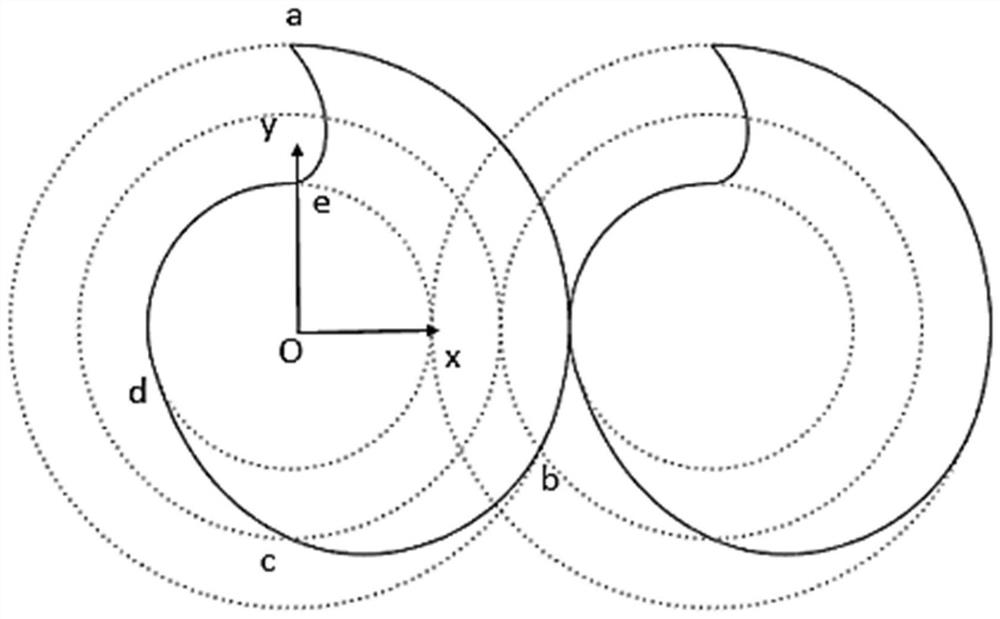

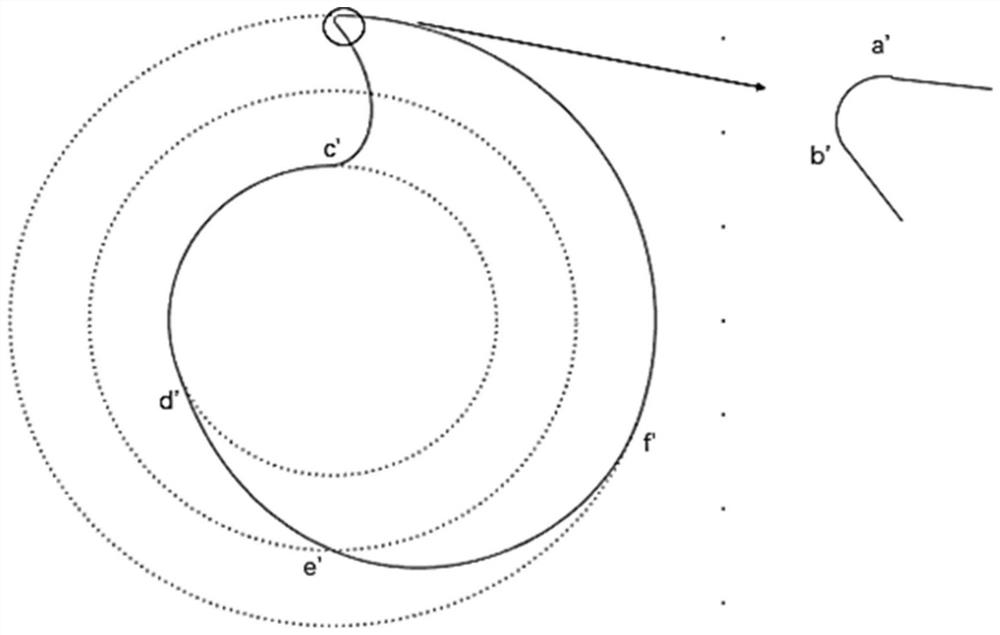

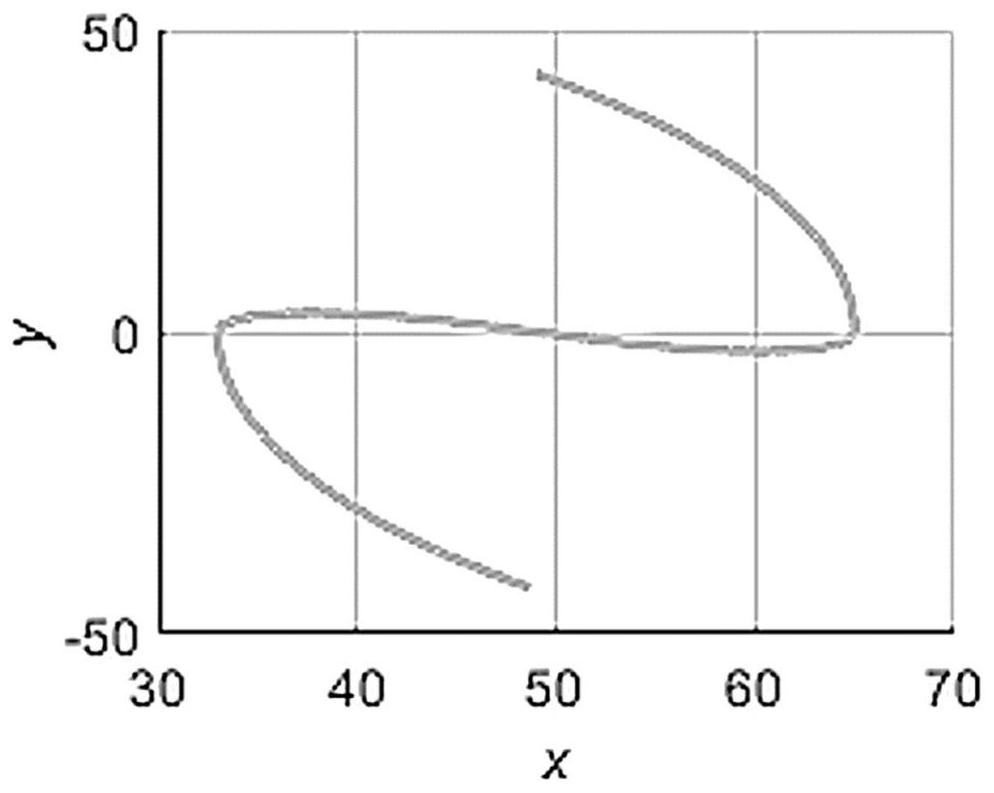

[0060] Take the addendum arc radius R=65mm, dedendum arc r=33mm, and small arc rr=1mm as an example, the profile line and contact line are as follows figure 2 , image 3 , Figure 4 as well as Figure 5 shown. The center distance of the male and female rotors in the rotor profile of the dry screw vacuum pump is:

[0061] A=R+r=98mm

[0062] The equation of the arc cycloid segment b'c' meshing with the corrected arc segment a'b' is:

[0063]

[0064] The equation of the modified arc segment a'b' is:

[0065]

[0066] where O 1 =(a,b)=(1.3061,63.9867),

[0067] The center of the circle is the intersection of the curve equidistant 1mm outside the arc cycloid segment b'c' and the circle with a radius of 64mm.

[0068] The arc cycloid segment b'c' is tangent to the circle of the corrected arc segment a'b', and the tangent point is N, and the coordinates of N points are brought into the equation of the corrected arc segment a'b' and the arc cycloid segment b The eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com