Toilet tank attachment bracket with unitary spring arm

A spring arm, water tank technology, used in flushing equipment with water tanks, flushing toilets, water supply devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

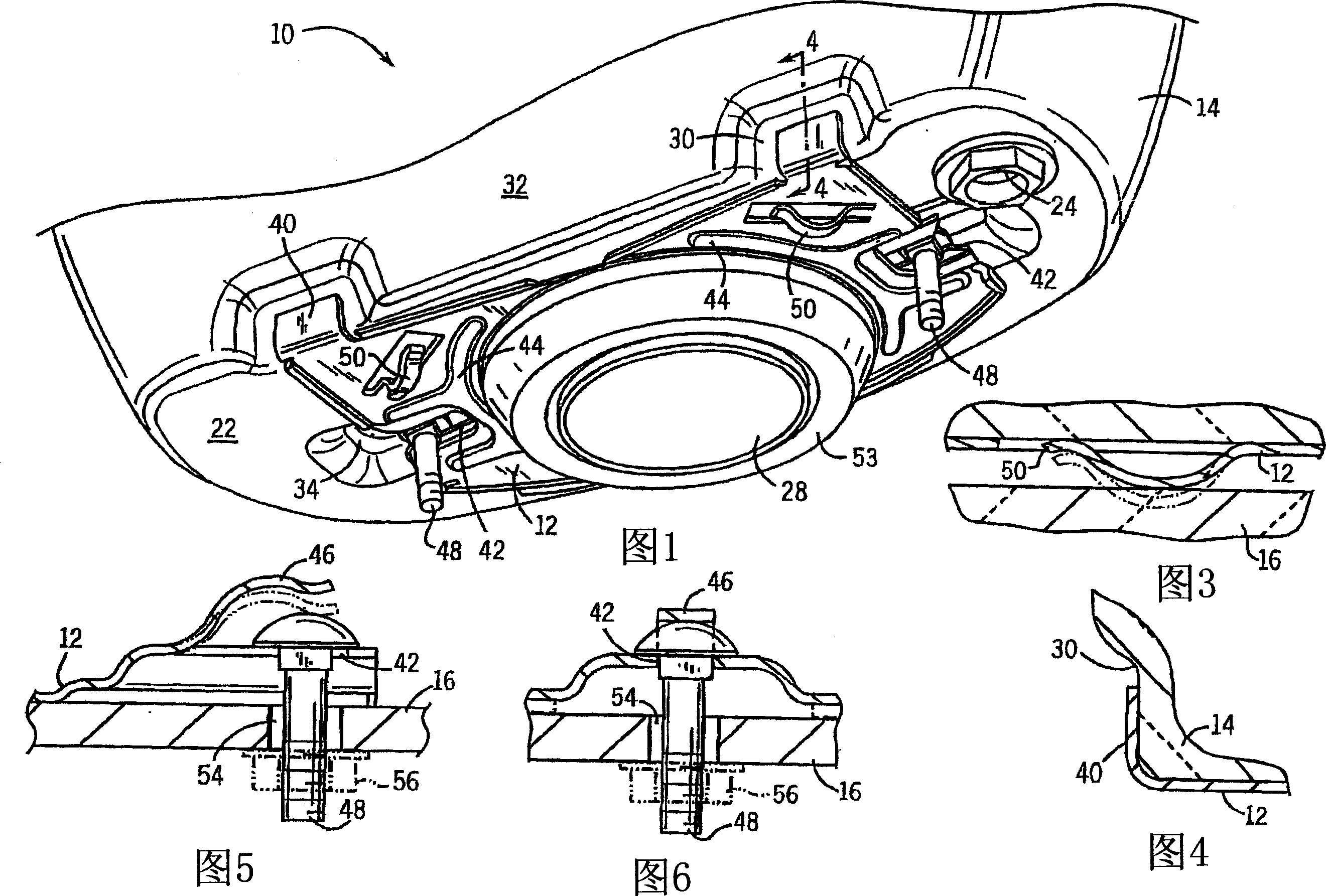

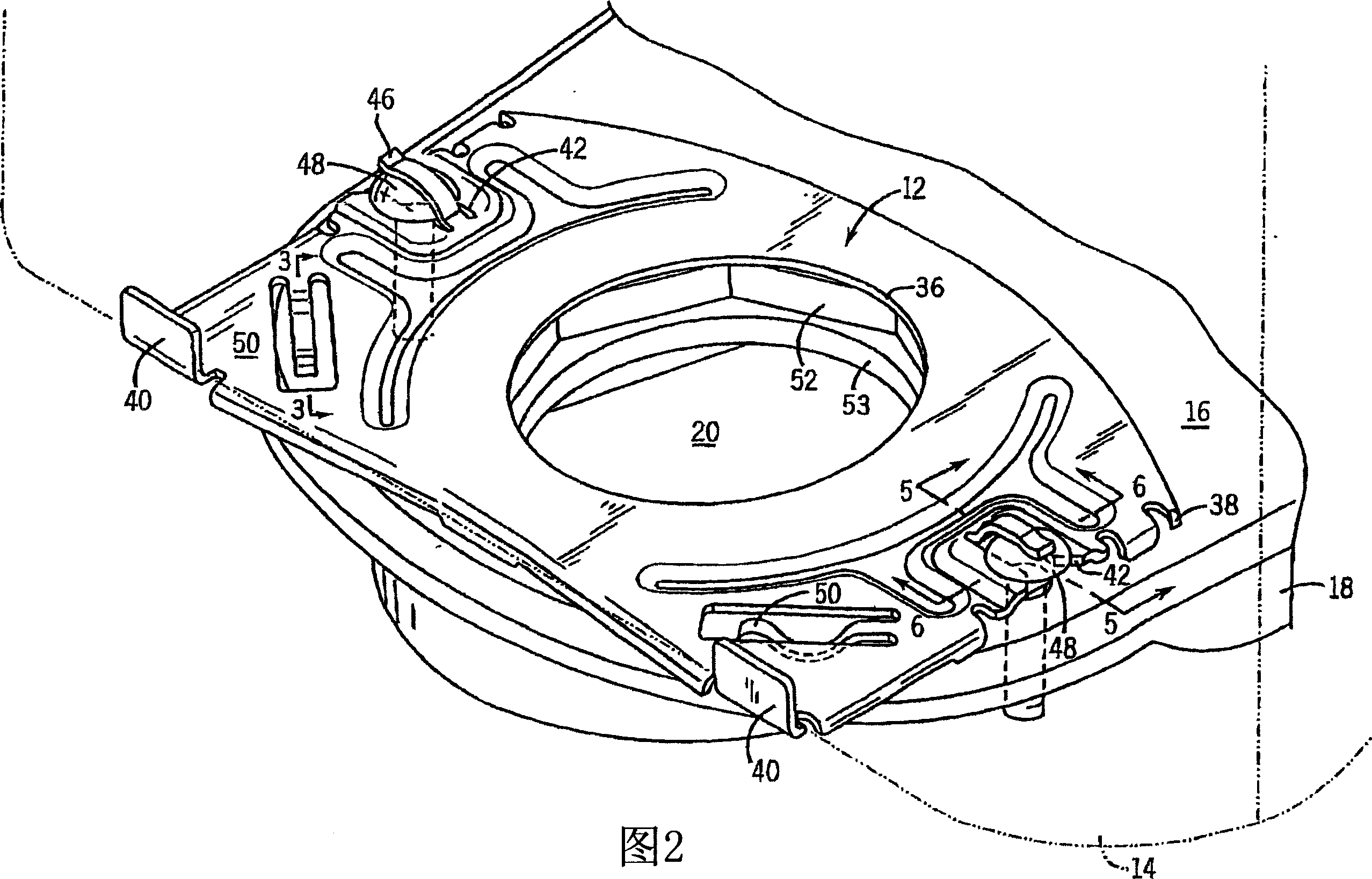

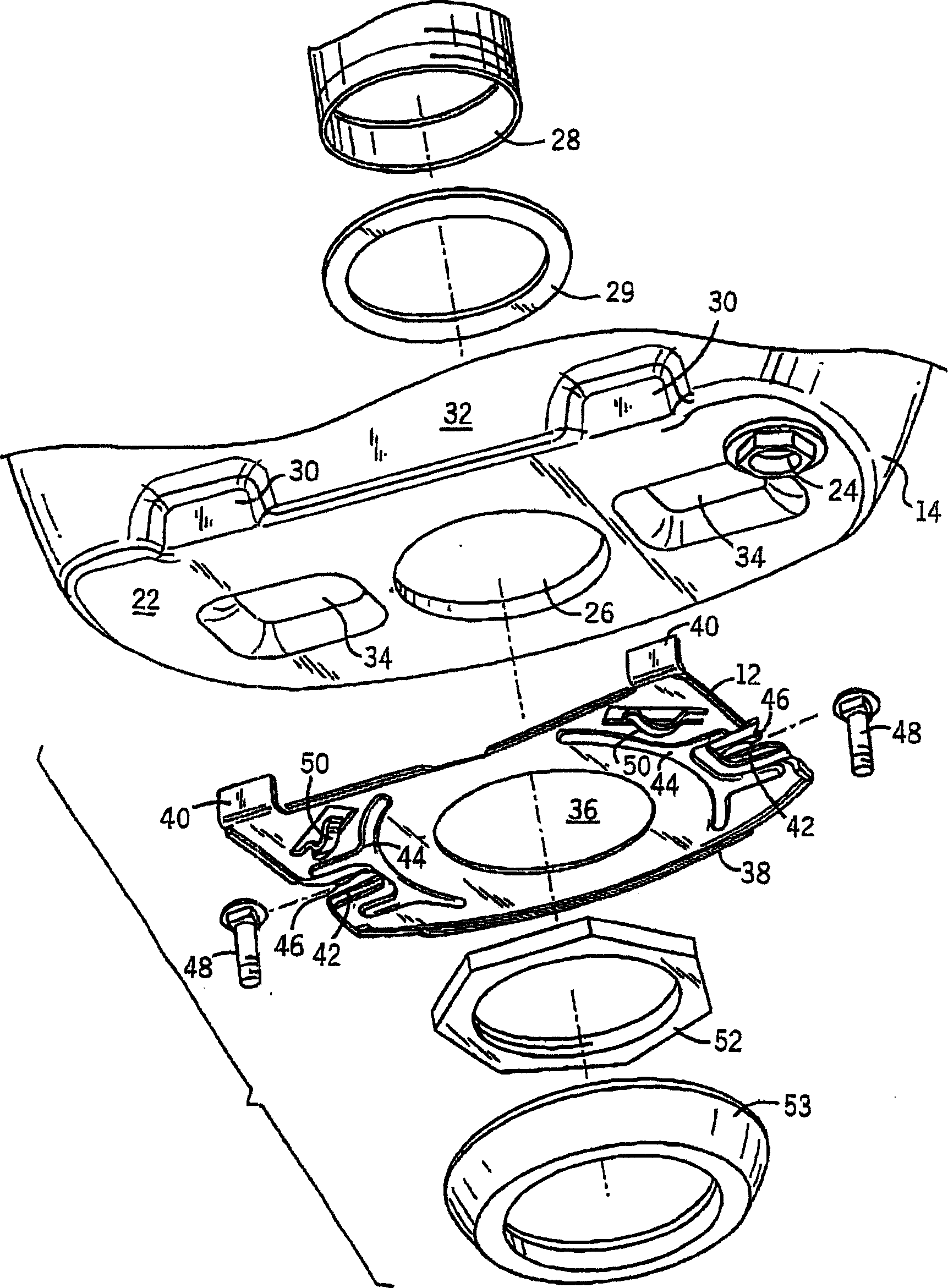

[0030] To attach the tank 14 to the toilet extension 16 of the toilet base 18 for a two-piece toilet (generally indicated at 10) having a bracket 12 according to the present invention, reference should first be made to FIGS. The toilet base 18 and its extension 16 are conventional components, molded from vitreous china or ceramic. As standard, the toilet extension 16 is formed with an opening 20 which leads to the toilet 16 (not shown). The cistern 14 is essentially a standard piece having a bottom wall 22 with a supply inlet 24 and a main flush opening 26 through which an extension 28 of a flush valve (not shown) passes and around which Partially equipped with gasket 29 (see Figure 7 ) to seal the flush port 26. However, the tank 14 also has two sets of recesses, one set of recesses 30 in the rear wall 32 of the tank and another set of recesses 34 in the bottom wall 22 of the tank, for receiving the components described below - the bracket 12 .

[0031] The bracket 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com