Automobile instrument panel transmission cam

A technology of automobile instrument panel and transmission cam, applied in the direction of cam, belt/chain/gear, mechanical equipment, etc., can solve the problem of unreasonable camshaft design, and achieve the effect of flexible rotation, large detection breadth and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

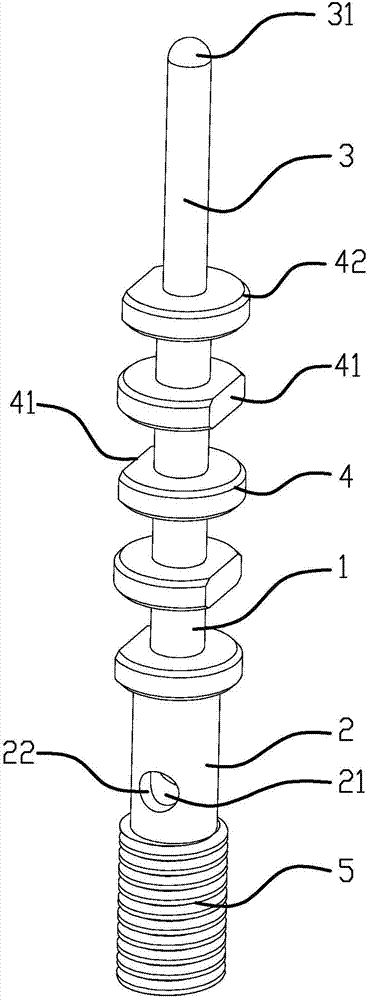

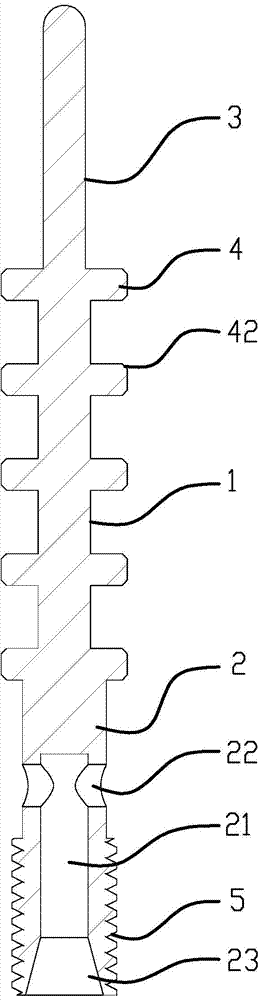

Image

Examples

Embodiment 1

[0029] The main material composition of the steel connection part 3 in this embodiment is (wt.%) carbon C: 0.05%; silicon carbide: 23%; manganese Mn: 0.30%; chromium Cr: 1.35%; aluminum Al: 1.00%; Molybdenum Mo: 0.15%; short carbon fiber (10-20 microns in length) 1.5%; the balance is Fe and unavoidable impurities, of which silicon carbide is whisker material and microcrystalline material (grain size is 0.1-2 Micron) mixture, the amount of whisker material added accounts for 5% of the total mass of silicon carbide. In the first mixing, the amount of ethanol added is 20% of the total volume of silicon carbide and carbon fiber short fibers; in the second mixing, add adjuvants to account for the total volume of whisker materials, microcrystalline materials, carbon fiber short fibers and alloy particles 20% of.

[0030]In this embodiment, the surface hardness of the connecting part 3 is HRC34, the tensile strength is 1300MPa, the yield strength is 1020MPa, and the elongation at br...

Embodiment 2

[0032] The main material composition of the steel connection part 3 in this embodiment is (wt.%) carbon C: 0.06%; silicon carbide: 25%; manganese Mn: 0.45%; chromium Cr: 1.40%; aluminum Al: 0.9%; Molybdenum Mo: 0.20%; short carbon fiber (10-20 microns in length) 1.3%; the balance is Fe and unavoidable impurities, of which silicon carbide is whisker material and microcrystalline material (grain size is 0.1-2 Micron) mixture, the amount of whisker material added accounts for 10% of the total mass of silicon carbide. In the first mixing, the amount of ethanol added is 25% of the total volume of silicon carbide and carbon fiber short fibers; in the second mixing, add admixtures to account for the total volume of whisker materials, microcrystalline materials, carbon fiber short fibers and alloy particles 17%.

[0033] In this embodiment, the surface hardness of the connecting part 3 is HRC34, the tensile strength is 1250MPa, the yield strength is 980MPa, and the elongation at brea...

Embodiment 3

[0035] The main material composition of the steel connection part 3 in this embodiment is (wt.%) carbon C: 0.07%; silicon carbide: 20%; manganese Mn: 0.35%; chromium Cr: 1.65%; aluminum Al: 0.8%; Molybdenum Mo: 0.25%; short carbon fiber (10-20 microns in length) 0.8%; the balance is Fe and unavoidable impurities, of which silicon carbide is whisker material and microcrystalline material (grain size is 0.1-2 Micron) mixture, the amount of whisker material added accounts for 15% of the total mass of silicon carbide. In the first mixing, the amount of ethanol added is 30% of the total volume of silicon carbide and carbon fiber short fibers; in the second mixing, add admixtures to account for the total volume of whisker materials, microcrystalline materials, carbon fiber short fibers and alloy particles 15%.

[0036] In this embodiment, the surface hardness of the connecting part 3 is HRC34, the tensile strength is 1330MPa, the yield strength is 1000MPa, and the elongation at bre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com