Method of utilizing swelling technology to prepare nanoscale electric jet-flow 3D printing injection needle

A nanoscale, 3D printing technology, applied in the direction of cleaning methods using liquids, nanotechnology, cleaning methods and appliances, etc., can solve the problems that are difficult to ensure the size, quality and cost of nano-spray needles, and achieve good protection, easy operation, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

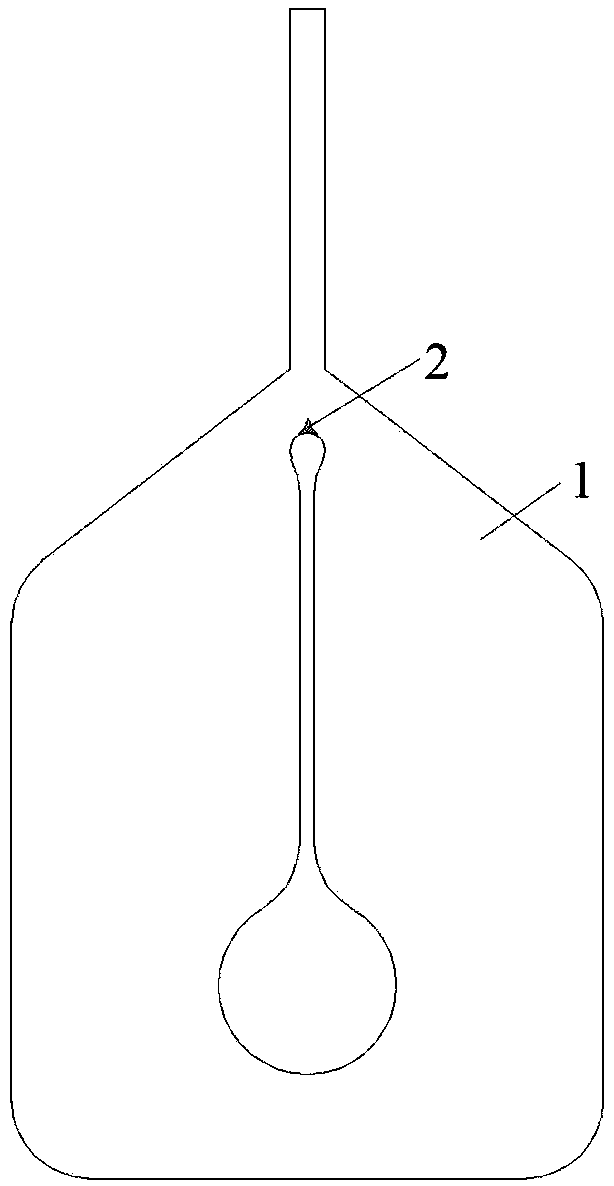

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

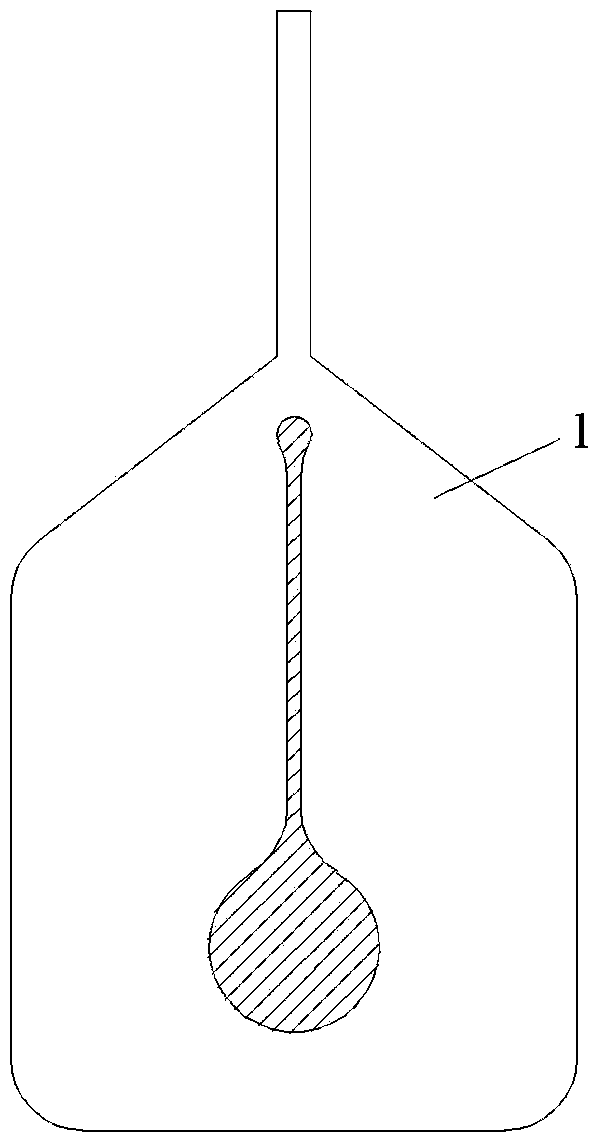

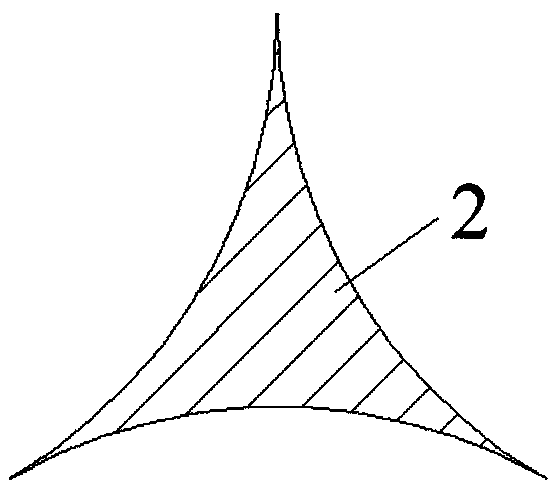

[0034] see Figure 1~6 As shown, the method for preparing nanoscale electrojet 3D printing needles using swelling technology of the present invention comprises the following steps:

[0035] (1) Nano-scale electro-jet 3D printing needle substrate laser cutting

[0036] The specific operation steps are:

[0037] (1a) Take a 5×5cm PMMA plastic substrate, and attach a layer of plastic wrap on the substrate, the purpose of which is to ensure that the surface material of the nanoscale electrojet 3D printing needle does not deteriorate during the laser cutting process;

[0038] (1b) Put the film-attached PMMA plastic substrate on the laser cutting machine, and cut it under the conditions of laser cutting current of 2.5-3mA and cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com