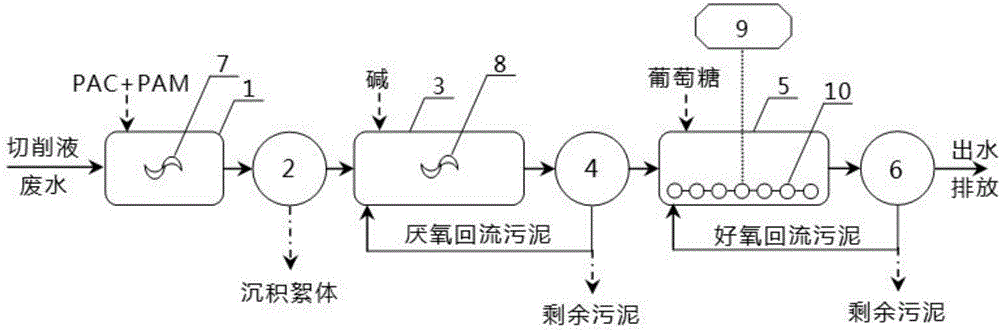

Coagulation-anaerobic hydrolysis-aerobic synergistic treatment cutting fluid wastewater device and method

An anaerobic hydrolysis and synergistic treatment technology, applied in aerobic process treatment, anaerobic digestion treatment, biological treatment equipment, etc., can solve the problems of slow growth and reproduction of anaerobic bacteria, collapse of anaerobic system, sensitivity to toxic substances, etc. Achieve the effect of improving biodegradability, reducing pollutant concentration, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

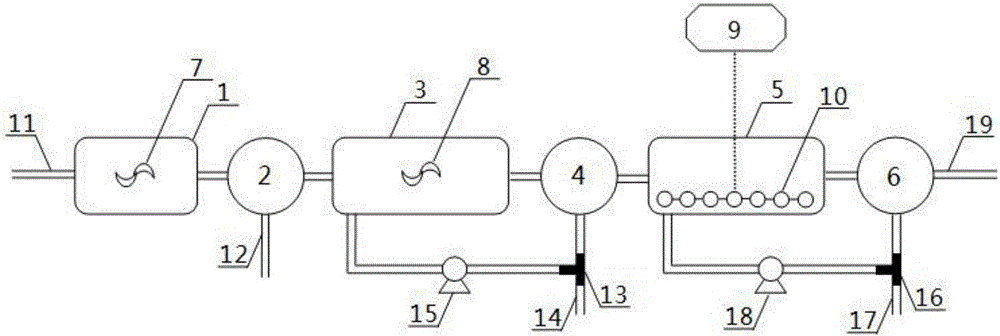

Method used

Image

Examples

Embodiment 1

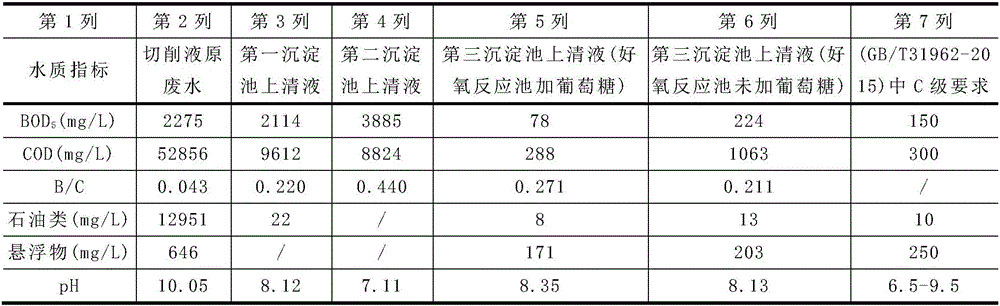

[0041] The cutting fluid wastewater discharged from a mechanical processing plant is operated through the method and parameters of the present invention, and after wastewater treatment, COD and BOD 5 , petroleum, suspended solids and pH all meet the requirements of the C-level discharge standard in the "Water Quality Standards for Discharge of Sewage into Urban Sewers (GB / T31962-2015)". See columns 1-5 and column 7 in Table 1 for details.

[0042] In order to verify the synergistic degradation effect of glucose on refractory organic matter in cutting fluid wastewater, the method of the present invention is also adopted to this cutting fluid wastewater, only glucose is not added in the aerobic reaction tank, and the operating parameters of other units are the same as listed in the present invention If they are the same, the effluent water quality of the third sedimentation tank is shown in column 6 in Table 1.

[0043] Comparing the data in columns 5 and 6 in Table 1, it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com