Steam turbine oil composite antioxidant as well as preparation method and addition method of steam turbine oil composite antioxidant

A composite antioxidant and turbine oil technology, which is applied in the field of turbine oil, can solve problems such as side reactions and adverse effects of oil quality, and achieve the effects of small changes in anti-emulsification performance, shallow oxidation stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Add 5.3g of mixed liquid shielding phenol, 4.2g of zinc dibutyldithiocarbamate and 1g of thiadiazole derivatives in 42g of formaldehyde aqueous solution (mass concentration 20%), and stir for 2h at 60°C and 500rm / min , and then moved into a stainless steel reactor, and reacted at 0.4MPa pressure and 150°C for 6h. The reaction product was taken out, moved to a distillation bottle for distillation and purification, and followed by crystallization and drying to obtain the composite antioxidant A for steam turbine oil.

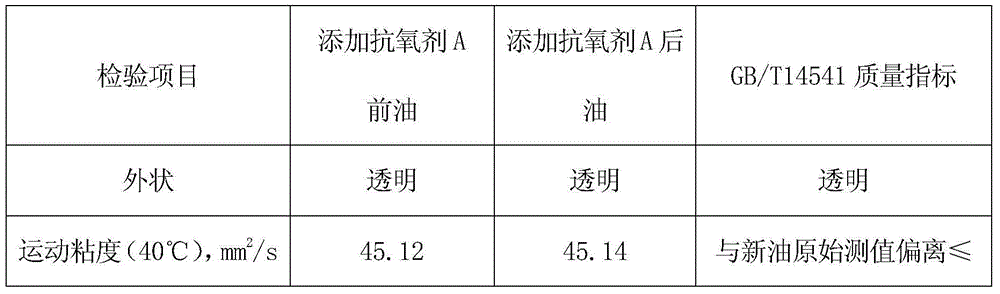

[0042] At 60°C, the prepared turbine oil composite antioxidant A was added to a No. 46 turbine oil (additive amount 0.6wt%) for effect test, and the test results are shown in Table 1.

[0043] Table 1 Comparison of oil quality indexes before and after adding antioxidant A

[0044]

[0045]

Embodiment 2

[0047] In 54g of acetaldehyde aqueous solution (mass concentration 30%), add 4.8g of 2,6-di-tert-butyl-p-cresol, 4.6g of alkyl diphenylamine, 5.5g of zinc dibutyldithiocarbamate and 3.1g of hetero Cyclic derivatives were stirred at 60°C for 3h at a speed of 800rm / min. After mixing evenly, move it into a high-pressure reactor with distillation function for reaction and distillation. The distillation product is filtered to remove waste residue (liquid), and after purification, crystallization and drying, composite antioxidant B for steam turbine oil is obtained.

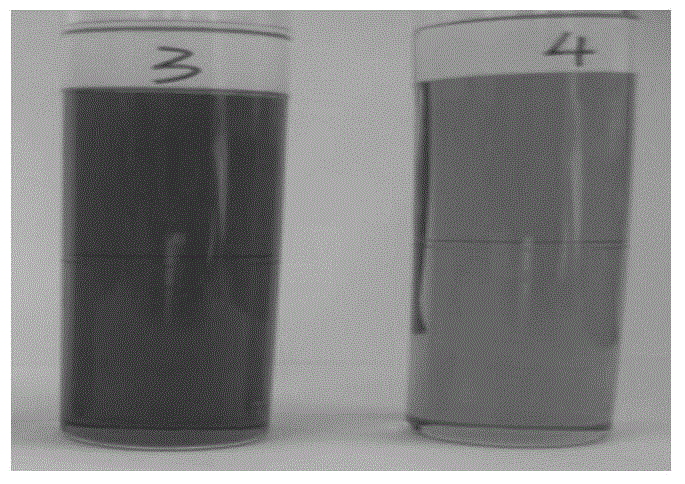

[0048] The prepared turbine oil composite antioxidant B was added to a certain No. 32 turbine oil at 55°C, the additive amount was 0.2wt%, and the anti-oxidation stability (rotational oxygen elasticity value) of the turbine oil before and after adding the antioxidant was tested. The results are shown in Table 2.

[0049] Table 2 Comparison of oil quality indexes before and after adding antioxidant B

[0050]

Embodiment 3

[0052] 9g alkyl diphenylamine, 4.8g N-phenyl-α-naphthylamine, 6.9g dialkyl dithiophosphoric acid mixture zinc and 2.3g heterocyclic derivatives are mixed, and with mass concentration be 35% formaldehyde aqueous solution (69g ) as a reaction reagent, stirred at 65°C and 650rm / min for 2h in a glass reactor with a stirring paddle, and then moved into a stainless steel autoclave. After replacing 2-3 times with nitrogen as a protective gas, the reaction was carried out at 0.5 MPa and 170° C. for 10 h. After the reaction is finished, it is often distilled under reduced pressure, purified, crystallized, and dried to obtain the composite antioxidant C for steam turbine oil.

[0053] At 65°C, the prepared turbine oil composite antioxidant C was added to a No. 32 turbine oil, the additive amount was 0.8wt%, and the antioxidant stability (rotational oxygen bomb value) of the turbine oil was tested before and after adding the antioxidant ) and other indicators. At the same time, the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com