Efficient emulsion breaker containing polymer for processing crude oil and preparation method thereof

A demulsifier and polymer technology, which is applied in the field of high-efficiency demulsifier for the treatment of crude oil containing polymers and its preparation, can solve the problems of reduced dehydration rate and slow dehydration speed, and achieve the effects of high dehydration rate and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis of phenolic resin:

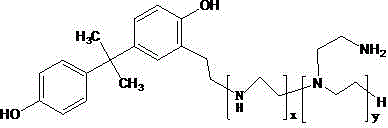

[0027] Add bisphenol A, tetraethylenepentamine and xylene into the reactor with stirring device, raise the temperature to 60°C, then add formaldehyde solution dropwise, keep the temperature at 70°C for polymerization reaction, then raise the temperature to 170°C at reduced temperature The xylene solvent and moisture are sloughed under the pressure condition, further condensation obtains phenolamine resin; In the phenolamine resin, bisphenol A, tetraethylenepentamine, weight percentage concentration are the formaldehyde solution three of 33% weight proportions as: 1: 6: 3; the molecular formula of phenolic amine resin is:

[0028]

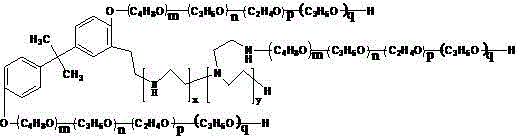

[0029] (2) Synthesis of phenolic resin initiator:

[0030] Add the phenolamine resin and potassium hydroxide catalyst obtained in step (1) into a closed nitrogen-protected reactor, stir, stop heating when the temperature rises to 130°C, open the feed valve, and slowly add butylene oxide to carry out poly...

Embodiment 2

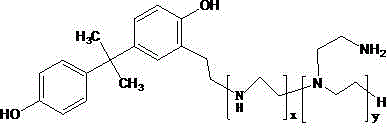

[0037] (1) Synthesis of phenolic resin:

[0038] Add bisphenol A, tetraethylenepentamine and xylene into the reactor with stirring device, raise the temperature to 50°C, then add formaldehyde solution dropwise, keep the temperature at 85°C for polymerization reaction, then rise to 160°C at reduced temperature The xylene solvent and moisture are sloughed under the pressure condition, further condensation obtains phenolamine resin; In the phenolamine resin, bisphenol A, tetraethylenepentamine, weight percentage concentration are the formaldehyde solution three of 33% weight proportions as: 1: 2: 5;

[0039] (2) Synthesis of phenolic resin initiator:

[0040] Add the phenolamine resin and potassium hydroxide catalyst obtained in step (1) into a closed nitrogen-protected reactor, stir, stop heating when the temperature rises to 130°C, open the feed valve, and slowly add butylene oxide to carry out polymerization reaction , ensure that the temperature is at 140°C, adjust the pres...

Embodiment 3

[0045] (1) Synthesis of phenolic resin:

[0046]Add bisphenol A, tetraethylenepentamine and xylene into the reactor with stirring device, raise the temperature to 70°C, then add formaldehyde solution dropwise, keep the temperature at 60°C for polymerization reaction, then raise the temperature to 180°C at reduced temperature The xylene solvent and moisture are sloughed under the pressure condition, further condensation obtains phenolamine resin; In the phenolamine resin, bisphenol A, tetraethylenepentamine, weight percentage concentration are the formaldehyde solution three of 33% weight proportions as: 1: 10: 0.5;

[0047] (2) Synthesis of phenolic resin initiator:

[0048] Add the phenolamine resin and potassium hydroxide catalyst obtained in step (1) into a closed nitrogen-protected reactor, stir, stop heating when the temperature rises to 130°C, open the feed valve, and slowly add butylene oxide to carry out polymerization reaction , make sure that the temperature is bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com