Crack pouring adhesive for concrete cracks and application of crack pouring adhesive

A technology for concrete and joint-filling glue, used in adhesives, epoxy resin glue, other chemical processes, etc., can solve the problems of poor bonding performance, poor permeability, poor permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

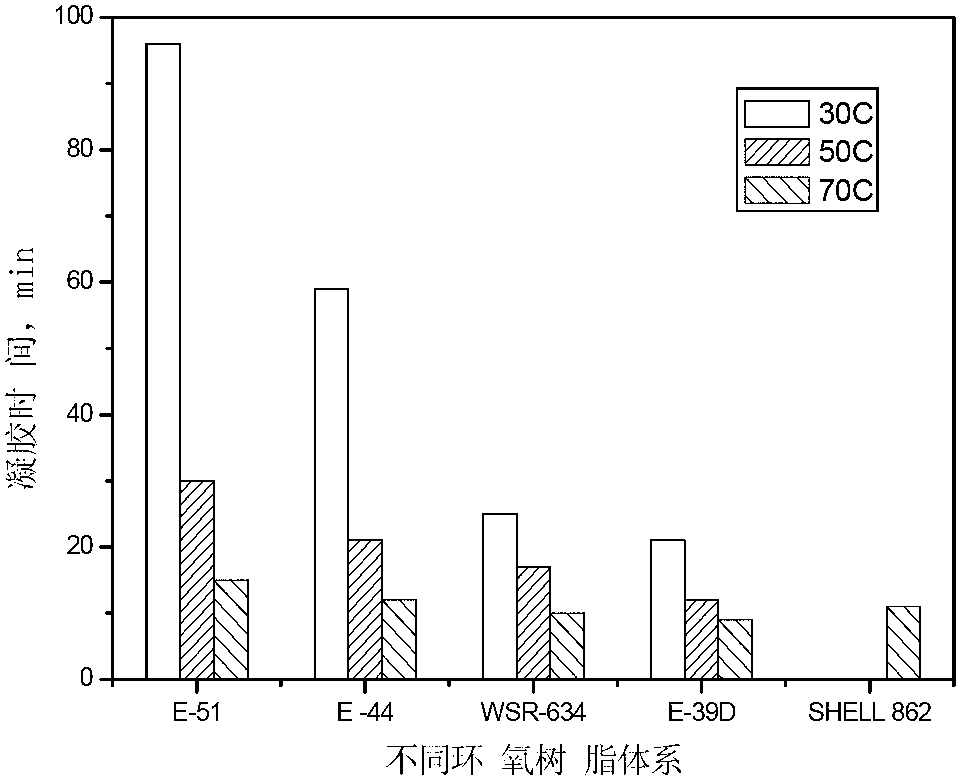

[0080] Embodiment 1, the preparation and performance of concrete cracks with potting glue

[0081] 1. Preparation of joint glue for concrete cracks

[0082] 1. Preparation of Component A and Component B

[0083] As shown in Table 5, the component A of this embodiment consists of 70 parts by mass of E-51 bisphenol A liquid epoxy resin (abbreviated as E-51), 30 parts by mass of 6002 bisphenol A liquid epoxy resin (abbreviated as 6002 ), 15-30 parts by mass of QS-BE toughening agent (abbreviated as BE), 5-15 parts by mass of benzyl glycidyl ether (abbreviated as 692) and 5-15 parts by mass of benzyl alcohol (abbreviated as BA).

[0084] Table 5. Composition of Fraction A

[0085] Material name parts by mass illustrate E-51 70 General purpose epoxy resin

[0086] 6002 30 Low Viscosity Epoxy Resin BE 15-30 Toughener 692 5-15 Thinner BA 5-15 Thinner

[0087] As shown in Table 6, component B of this embodiment consis...

Embodiment 2

[0118] Embodiment 2, engineering application of concrete cracks with potting glue

[0119] In October 2012, concrete cracks in Example 1 were used for concrete cracks with 1-3# / 2-2# for actual trial application in a concrete bridge in Beijing. The specific experimental method is as follows: measure cracks by crack width gauge Width, for cracks ≥ 1.5mm, use an electric angle grinder to polish and clean the surface first, clean with acetone or alcohol, paste the glue nozzle every 20-40cm, and then use the concrete cracks in Example 1 to seal the cracks with glue, After curing, the glue is poured through the glue pouring equipment. After the pouring is completed 24 hours, the core is taken on site with a rhinestone. The results show that the concrete cracks are full of cracks with 1-3# / 2-2# cracks ( figure 1 with figure 2 ), indicating that the cement for concrete cracks of the present invention has good constructability and pourability.

[0120] Wherein, the concrete cracks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com