Composite for treating myelodysplastic syndrome and preparation method thereof

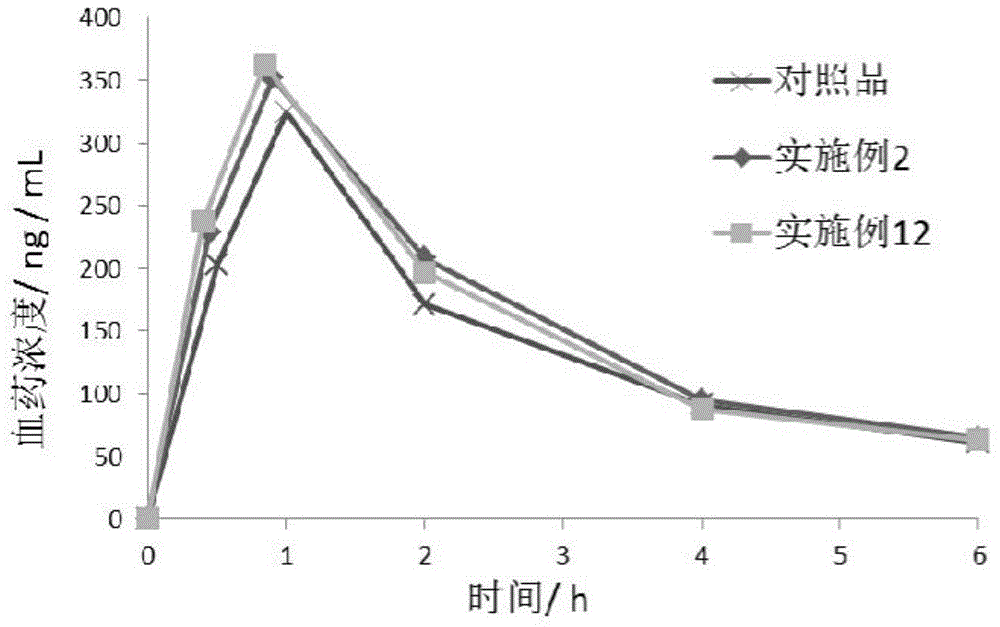

A technology for myelodysplasia and composition, which is applied in the direction of drug combination, medical preparations with non-active ingredients, non-active ingredients of polymer compounds, etc., can solve the factors that affect the porosity of granulation and the reproducibility of specific surface area. , The drug dissolution stability is greatly affected, and the granulation and drying take a long time to achieve the effect of improving the bioavailability of the drug, solving the adhesion of the excipients, and improving the bioavailability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

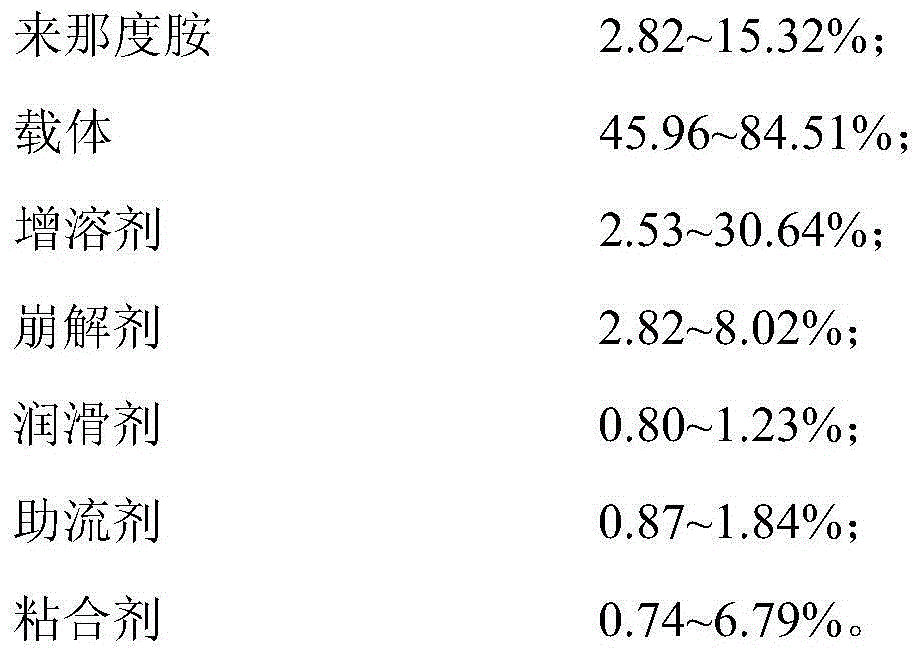

[0051] A composition for treating myelodysplastic syndrome, which is a lenalidomide tablet, comprising the following components (in 1000 tablets):

[0052]

[0053]

[0054] Its preparation method comprises the following steps:

[0055] (1) Grinding: Lenalidomide, polyvinyl alcohol and hydroxypropyl-β-cyclodextrin are placed in a grinding machine and ground to obtain a solid dispersion of 40-100 meshes;

[0056] (2) Mixing: After the solid dispersion obtained in (1) is evenly mixed with povidone, 1 / 2 formula amount of low-substituted hydroxypropyl cellulose and about 2 / 3 formula amount of micropowder silica gel, mix with 1 / 2 formula amount of micropowder silica gel. Polyoxyethylene monostearate is mixed to obtain a premix;

[0057] (3) granulation: the premix obtained in (2) is compressed into large pieces or plates, and the granules are pulverized and granulated through an 8-30 mesh sieve to obtain drug-containing granules;

[0058] (4) Mixing: mixing the drug-contain...

Embodiment 2

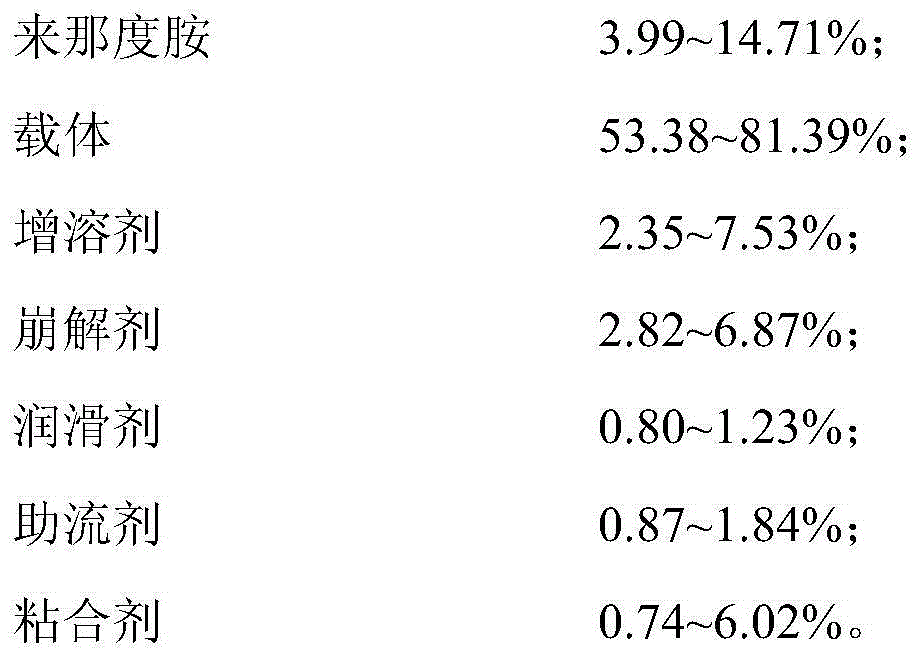

[0062] A composition for treating myelodysplastic syndrome, which is a lenalidomide tablet, comprising the following components (in 1000 tablets):

[0063]

[0064] Its preparation method is as follows:

[0065] (1) Grinding: Lenalidomide, polyethylene glycol 6000, microcrystalline cellulose and sodium lauryl sulfate are placed in a grinder and ground to obtain a solid dispersion of 40-100 meshes;

[0066] (2) Mixing: After the solid dispersion obtained in (1) is evenly mixed with povidone, 1 / 2 formula amount of low-substituted hydroxypropyl cellulose and about 2 / 3 formula amount of micropowder silica gel, mix with 1 / 2 formula amount of micropowder silica gel. Talc powder is mixed to obtain a premix;

[0067] (3) granulation: the premix obtained in (2) is compressed into large pieces or plates, and the granules are pulverized and granulated through an 8-30 mesh sieve to obtain drug-containing granules;

[0068] (4) total mixing: mixing the drug-containing granules of (3) ...

Embodiment 3

[0072] A composition for treating myelodysplastic syndrome, which is a lenalidomide tablet, comprising the following components (in 1000 tablets):

[0073]

[0074] Its preparation method is as follows:

[0075] (1) Grinding: Lenalidomide, microcrystalline cellulose and poloxamer are placed in a grinding machine and ground to obtain a solid dispersion of 40-100 meshes;

[0076] (2) Mixing: Mix the solid dispersion obtained in (1) with povidone, calcium carboxymethyl cellulose of 1 / 2 formula and powdered cellulose of about 2 / 3 formula, and mix with 1 / 2 formula. Amount of talc is mixed to obtain a premix;

[0077] (3) granulation: the premix obtained in (2) is compressed into large pieces or plates, and the granules are pulverized and granulated through an 8-30 mesh sieve to obtain drug-containing granules;

[0078] (4) total mixing: the medicated granules of (3) gained, the calcium carboxymethyl cellulose of surplus and powdery cellulose are mixed for 10min, and then the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com