Method for rapidly manufacturing nano-palladium/iron with scattered dispersing agent and scattered surface active agent

A surfactant and dispersant technology, applied in the field of nano-environmental functional materials and environmental remediation, can solve the problems of difficult removal of chlorinated organic pollutants, incomplete degradation of chlorinated organic pollutants, etc., and achieves short reaction time and good stability. The effect of sex, simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

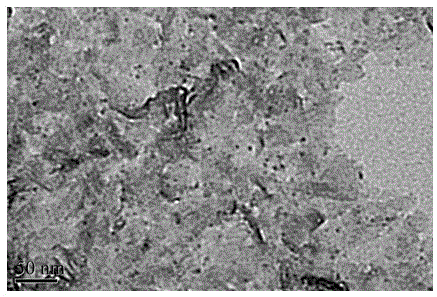

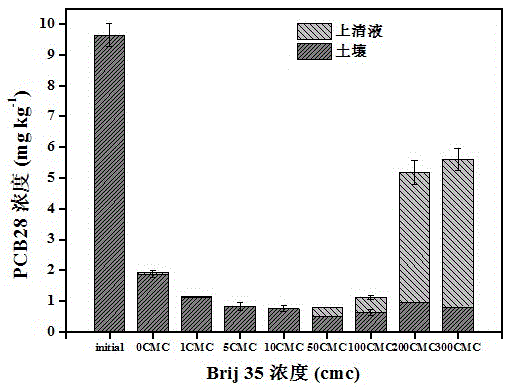

[0013] Example 1: A rapid preparation method for dispersing nano-palladium / iron with a dispersant and a surfactant and its effect on the removal of polychlorinated biphenyls (PCB28) in soil. The specific content is as follows: (1) Pass ultrapure water into Nitrogen deoxygenated for 15 minutes for later use; (2) Dissolve 1.92g of CMC in 200mL of deoxygenated water to make a CMC aqueous solution (0.8%w / w). (3) In a 500mL three-legged flask, 200mL of CMC aqueous solution was passed through nitrogen for 15min, and then 20mL of freshly prepared FeSO 4 ·7H 2 O (0.42mol / L) aqueous solution was added to the CMC aqueous solution, and nitrogen gas was continued for 15 minutes at a stirring speed of 150r / min to ensure that the CMC-Fe 2+ The formation of complexes, and drive away the oxygen in the solution and the air. (4) Add 0.91gKBH 4 Add to 20mL deoxygenated ice water to make 0.84mol / L KBH 4 Aqueous solution, drop this aqueous solution into Fe at a constant speed 2+ - In the CMC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com