Reactive polyurethane hot melt adhesive with low wall removal rate, and preparation method thereof

A polyurethane hot-melt adhesive, reactive technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low wall peeling rate and high wall peeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

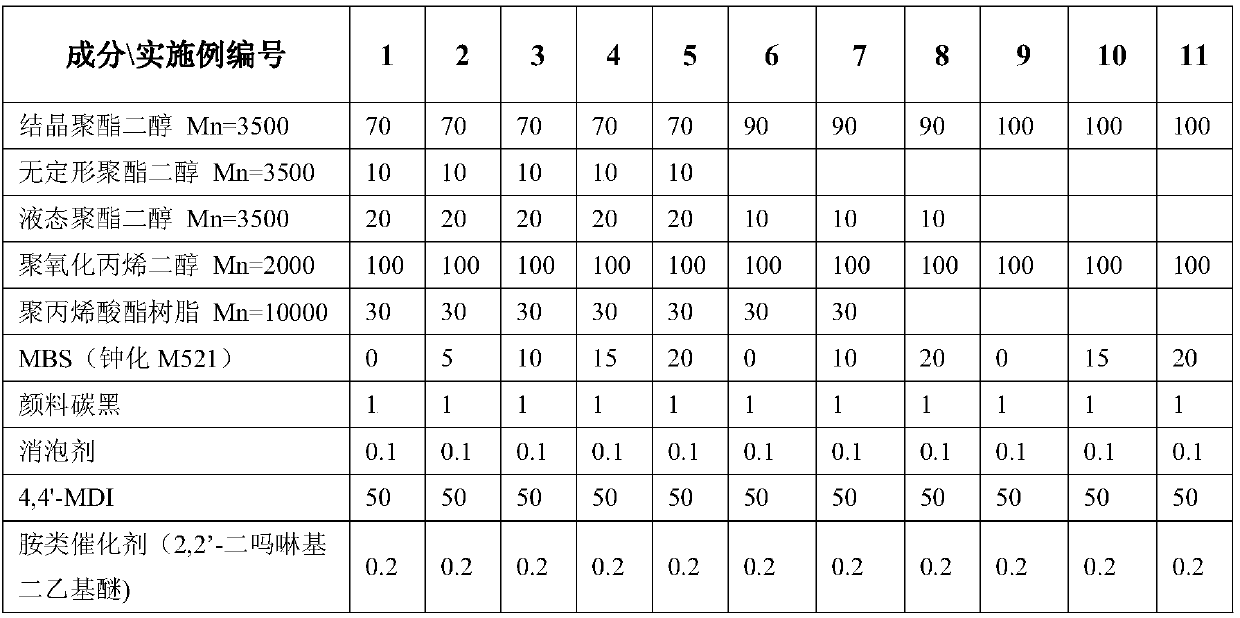

[0041] The components of the reactive polyurethane hot-melt adhesive with low wall removal rate are shown in Table 1.

[0042] The composition formula (unit: parts by weight) of hot melt adhesive provided by Table 1 embodiment 1~11

[0043]

Embodiment 12

[0045] This example is used to investigate the performance of the reactive polyurethane hot-melt adhesive with low wall-off rate provided in the above examples 1-11.

[0046] 1. The test method of the wall-off rate is: after the HM PUR glue packed in an aluminum foil bag is stored at room temperature for 30 days, the aluminum foil bag is torn off, the amount of glue with wall-off phenomenon is observed and counted, and the wall-off rate is calculated. The calculation method is: the number of HMPUR with detachment / total number*100%

[0047] 2. The test method for the initial bonding strength and final bonding strength of a reactive polyurethane hot melt adhesive with a low wall-off rate is: melt the glue, squeeze it onto a PC sheet of 100mm*25mm*3mm under pressure, and use another A PC sheet of the same size is overlapped, the overlapping area is 25mm*10mm, and the thickness is 100μm. Cured in an environment of 25±2℃, 50±5%RH for 30 minutes, and immediately tested the tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com