Disperse dye ink with good storage stability and good redispersibility and preparation method

A storage stability, disperse dye technology, applied in dyeing, ink, textile and papermaking, etc., can solve the problems of wide particle size distribution, easy clogging of nozzles, restricting wide application, etc., to reduce VOC emissions and improve redispersion. performance, the effect of improving dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

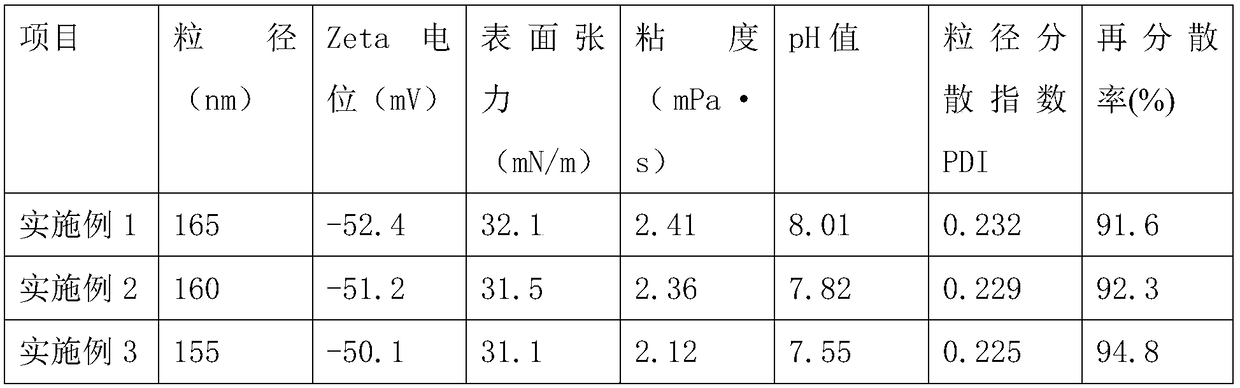

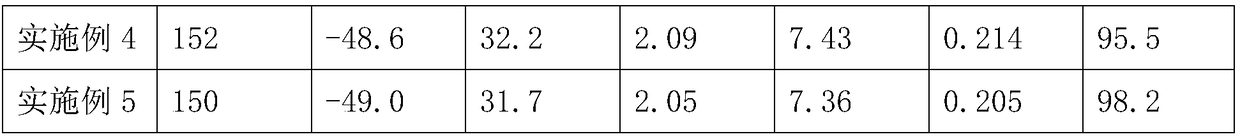

Examples

Embodiment 1

[0031] A disperse dye ink with good storage stability and redispersibility, comprising the following components by mass parts: 30 parts of high-purity water, 10 parts of C.I.Disperse Blue359, 8 parts of composite dispersant, 5 parts of lubricant, 6 parts of ethylene glycol Part, 1 part of sodium lauryl sulfate;

[0032] The composite dispersant is composed of a main dispersant and an auxiliary dispersant, and the mass ratio of the main dispersant to the auxiliary dispersant is 2:1; the main dispersant is composed of a polymer dispersant, and the polymer dispersant Be selected from the JoncrylHPD 196 of BASF company; Described auxiliary dispersant is made up of naphthalenesulfonic acid formaldehyde condensate and lignosulfonate sodium, and the mass ratio of described naphthalenesulfonic acid formaldehyde condensate and lignosulfonate is 1:1, The sodium lignosulfonate is selected from Reax907 of MedeVistec, and the naphthalenesulfonic acid formaldehyde condensate is selected fro...

Embodiment 2

[0039]A disperse dye ink with good storage stability and redispersibility, comprising the following components by mass parts: 35 parts of high-purity water, 15 parts of C.I.Disperse Red 60, 12 parts of composite dispersant, 9 parts of lubricant, ethylene glycol 8 parts, 5 parts of sodium dibutyloctyl maleate sulfonate;

[0040] The composite dispersant is composed of a main dispersant and an auxiliary dispersant, and the mass ratio of the main dispersant to the auxiliary dispersant is 5:1; the main dispersant is composed of a polymer dispersant, and the polymer dispersant Be selected from the Jouncy HPD671 of BASF company; Described auxiliary dispersant is made up of naphthalenesulfonic acid formaldehyde condensate and sodium lignosulfonate, and the mass ratio of described naphthalenesulfonic acid formaldehyde condensation product and sodium lignosulfonate is 3:1, The sodium lignosulfonate is selected from Reax 85A of MetWistevek Company, and the naphthalenesulfonic acid forma...

Embodiment 3

[0047] A disperse dye ink with good storage stability and redispersibility, comprising the following components by mass parts: 34 parts of high-purity water, 12 parts of C.I.Disperse Yellow 54, 10 parts of composite dispersant, 7 parts of lubricant, ethylene glycol 7 parts, 3 parts of sodium lauryl sulfate;

[0048] The composite dispersant is composed of a main dispersant and an auxiliary dispersant, and the mass ratio of the main dispersant to the auxiliary dispersant is 4:1; the main dispersant is composed of a polymer dispersant, and the polymer dispersant Be selected from the JoncrylHPD 696 of BASF company; Described auxiliary dispersant is made up of naphthalenesulfonic acid formaldehyde condensate and lignosulfonate sodium, and the mass ratio of described naphthalenesulfonic acid formaldehyde condensate and lignosulfonate is 2:1, The sodium lignosulfonate is selected from Reax LS of MetWistevek, and the naphthalenesulfonic acid formaldehyde condensate is selected from D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com