Online abrasion detection method and system for pantograph of electric locomotive

A technology for electric locomotives and detection methods, applied in the direction of optical testing flaws/defects, etc., can solve the problems of low reliability, inability to fully reflect the wear of the pantograph, complex system structure, etc., and achieve the effect of improving accuracy and real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

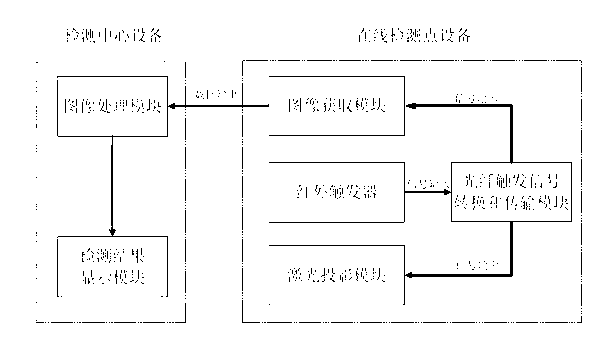

[0024] like figure 1 As shown, an electric locomotive pantograph on-line wear detection system includes on-line monitoring point equipment and testing center equipment.

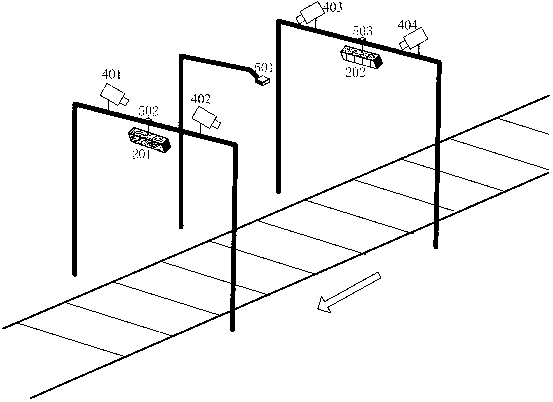

[0025] figure 2 It is a schematic diagram of the online detection point equipment. Column 1, column 2 and column 3 have the same height, infrared trigger 101 is installed on column 2, digital cameras 401, 402 and line laser array 201 are installed on column 1, digital cameras 403, 404 and line laser array 202 are installed on on column 3.

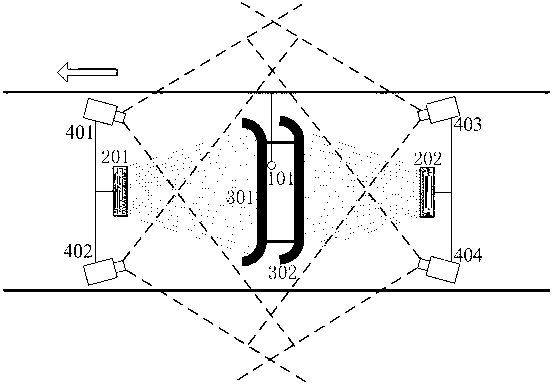

[0026] image 3 It is a top view of the online detection point equipment. A pantograph includes two pantograph graphite strips 301 and 302 . The digital cameras 401 and 402 take pictures in a backward and downward manner, and the overlapping field of view of the two includes the pantograph graphite strip 301 . The digital cameras 403 and 404 take pictures in a forward and downward manner, and the overlapping range of their fields of view includes the pantograph gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com