Sand-preventing sealing device of submersible electric pump

A technology for sealing devices and submersible electric pumps, which is applied to pump devices, parts of pumping devices for elastic fluids, pumps, etc., and can solve problems such as seal failure of submersible electric pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

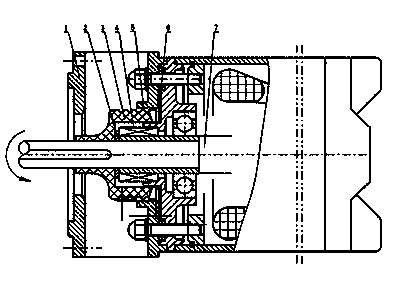

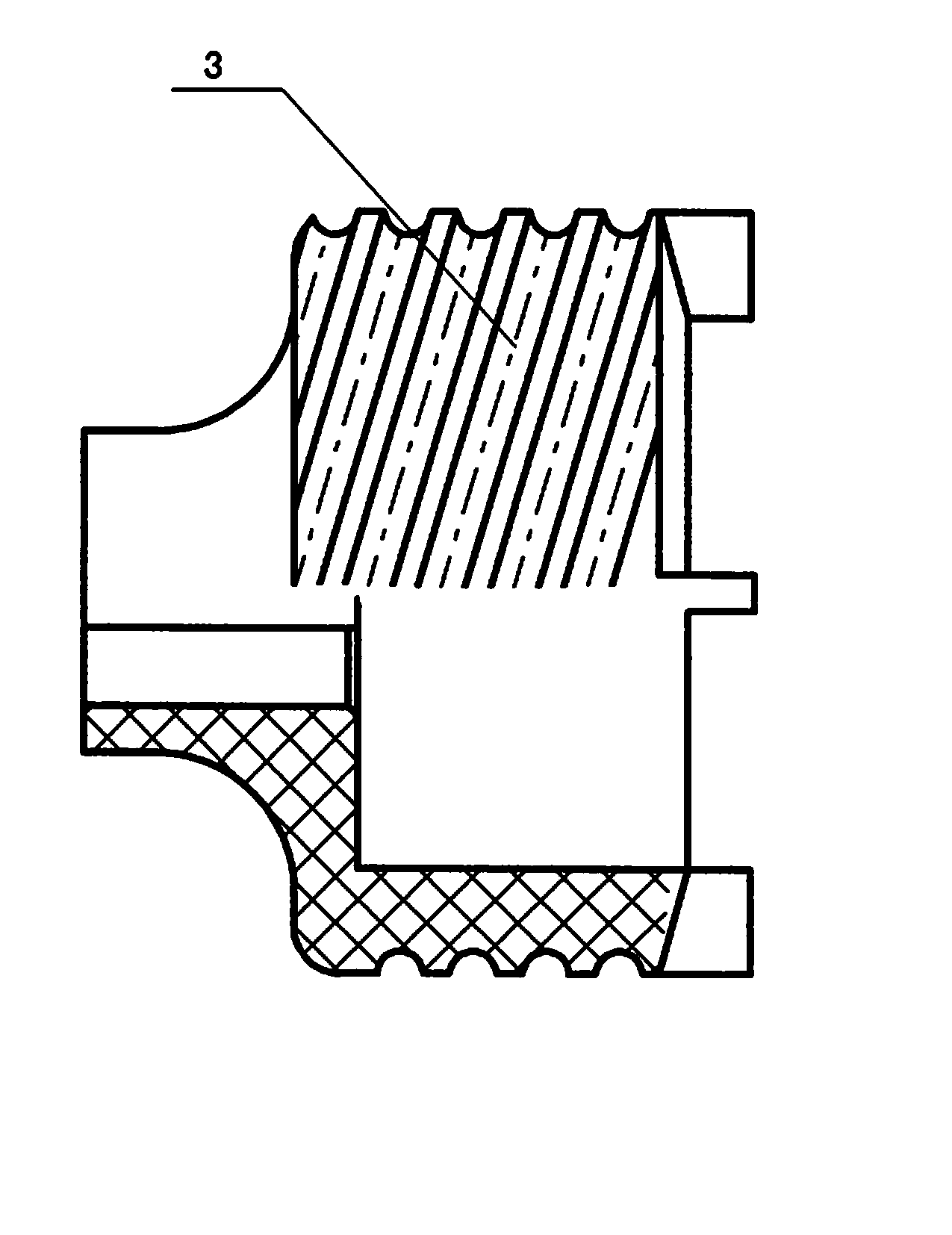

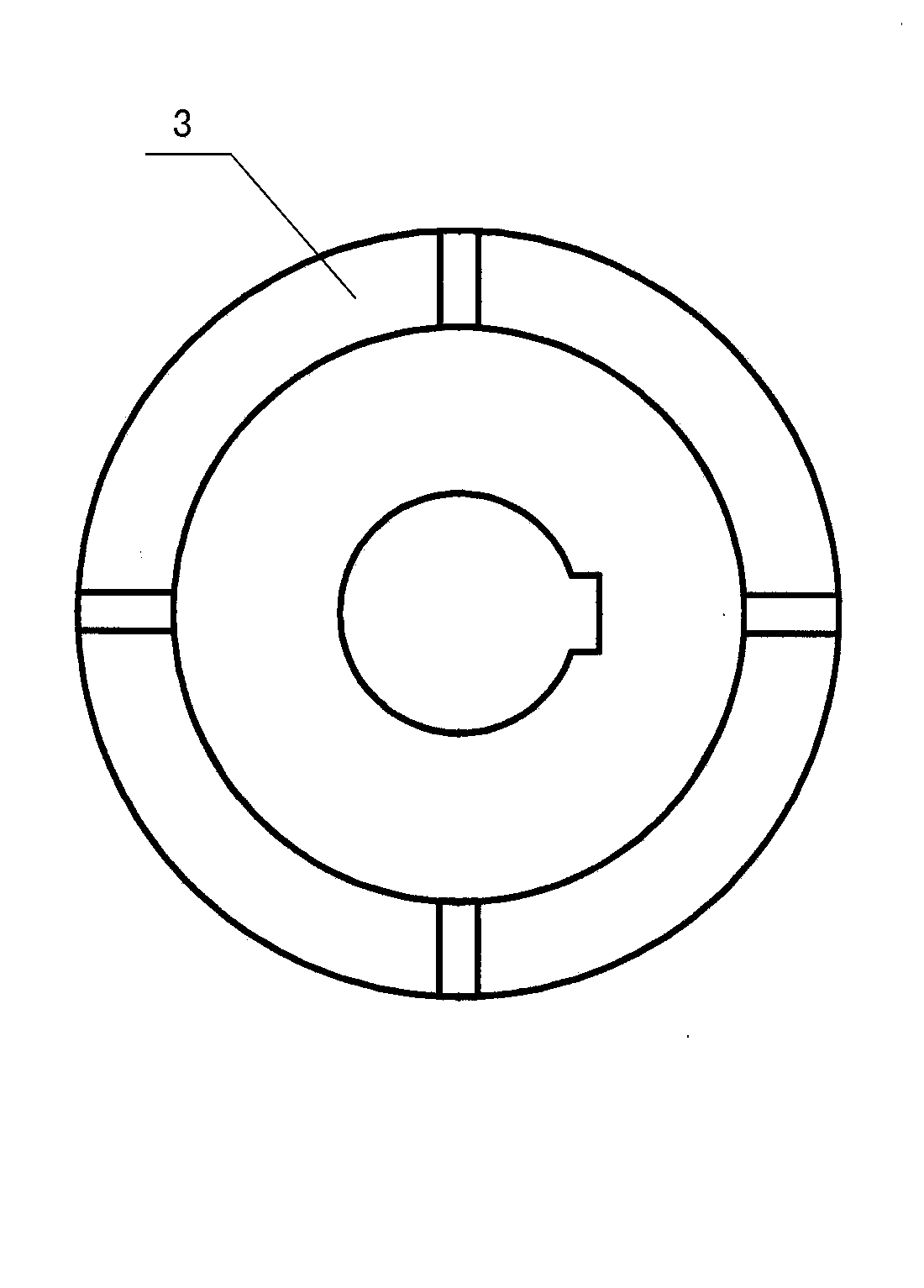

[0012] according to figure 1 , figure 2 , image 3 As shown, a sand control sealing device for a submersible electric pump, the device is located between the motor and the water pump, the device is provided with a double helix sand throwing ring 3, and the double helix sand throwing ring 3 is sleeved on the rotor shaft 7 of the motor , A sand discharge ring 5 is fixed on the motor bearing seat, and there is a gap between the inner hole of the sand discharge ring 5 and the outer circle of the spiral sand throwing ring 3 .

[0013] The motor rotor shaft 7 of the present invention and the double-helix sand throwing ring 3 are covered with a metal gasket 2, and the double-helix sand throwing ring 3 is fixed by the metal gasket 2 at one end and the connecting flange 1 at the other end, and then fixed by the metal gasket The internal mechanical seal or skeleton oil seal 4 is fixed and sealed. The outer periphery of one end of the double-helix sand rejection ring 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com