Bearing for mahjong machine

A mahjong machine and bearing technology, applied in the field of bearings, can solve the problems of high cost of bearings, complex manufacturing processes, low bearing manufacturing efficiency, etc., and achieve the effects of simple and fast assembly, not easy to wear, and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

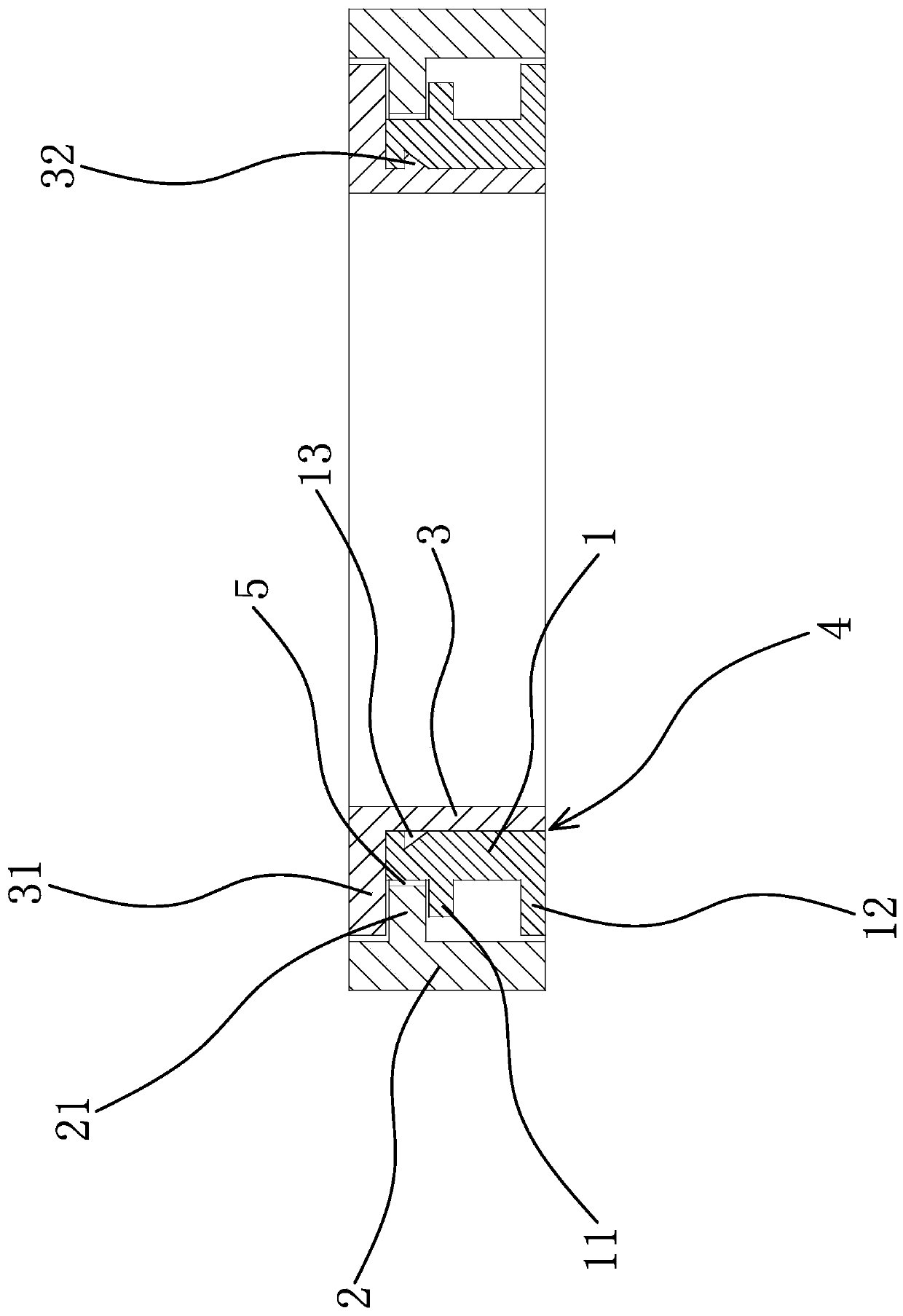

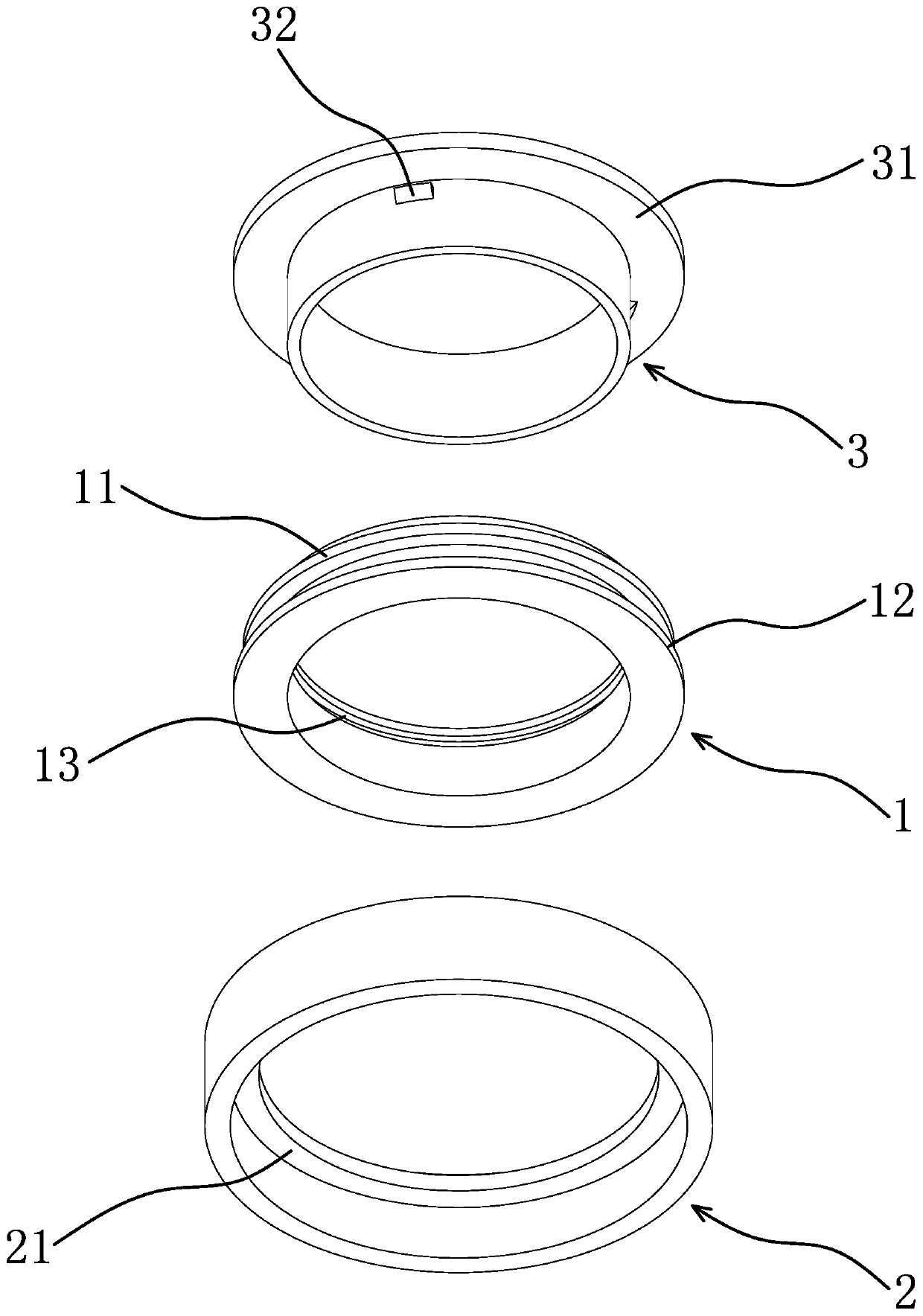

[0025] Such as figure 1 and figure 2 As shown, the bearing for this mahjong machine includes a rotating sleeve 1, a rotating sleeve 2 and a positioning sleeve 3, the rotating sleeve 1 is set on the outer peripheral surface of the positioning sleeve 3, and the positioning sleeve 3 and the rotating sleeve 1 are clamped and fixed to form The rotating body 4, the outer peripheral surface of the positioning sleeve 3 has an annular convex edge 1 31, the outer peripheral surface of the rotating sleeve 1 has an annular convex edge 2 11, an annular groove 5 is formed between the annular convex edge 1 31 and the annular convex edge 11, and the annular Convex edge one 31 or / and annular convex edge two 11 are sleeved on the inner peripheral surface of rotating sleeve two 2, and the inner peripheral surface of rotating sleeve two 2 has annular convex edge three 21 extending into the annular groove 5, and annular convex edge one 31 and annular convex edge 2 11 play the role of upper and l...

Embodiment 2

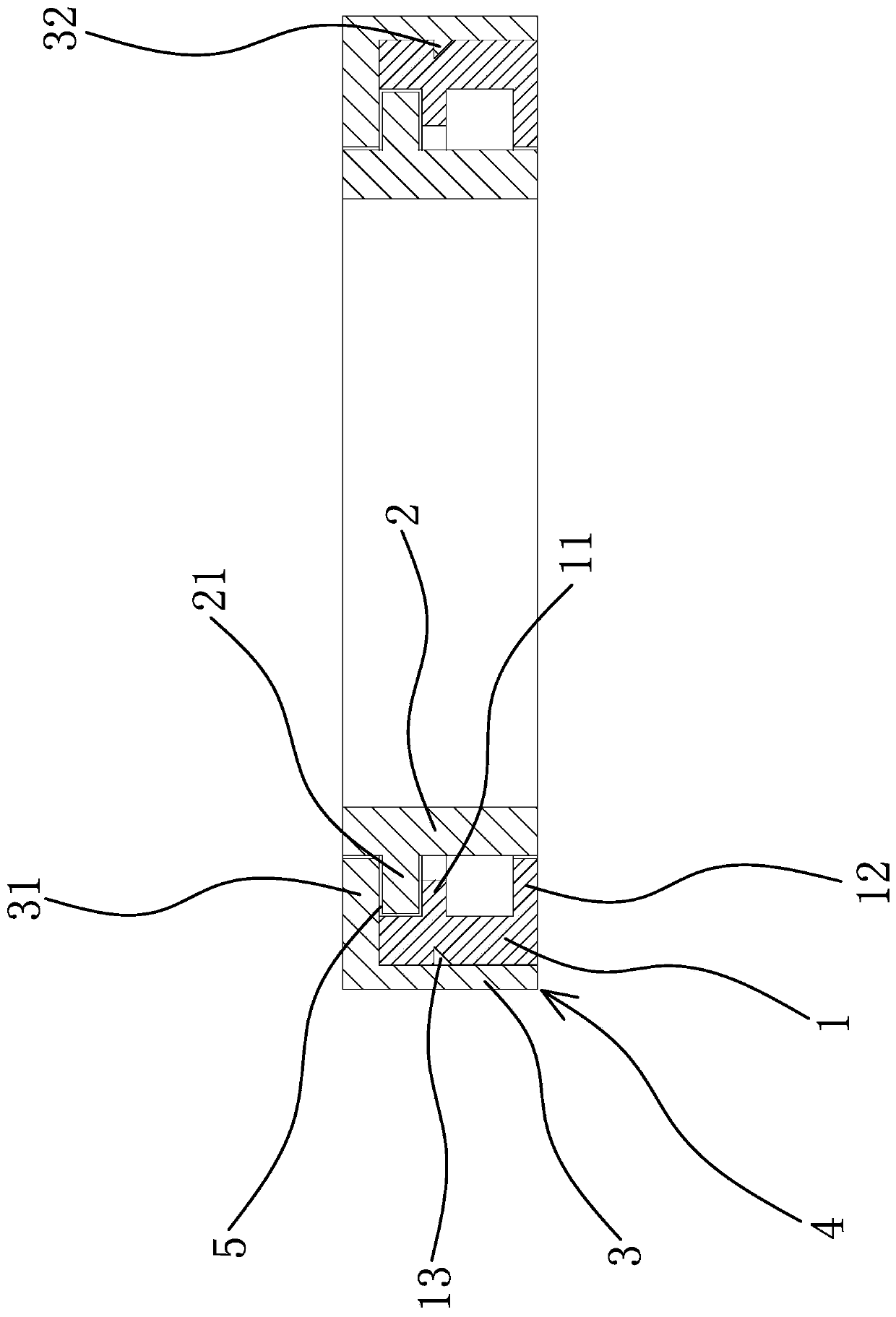

[0029] Such as image 3 and Figure 4 As shown, the bearing for this mahjong machine comprises a rotating sleeve 1, a rotating sleeve 2 and a positioning sleeve 3, and the rotating sleeve 1, rotating sleeve 2 and positioning sleeve 3 are all made of plastic materials, and the rotating sleeve 1 is set On the inner peripheral surface of the positioning sleeve 3, the positioning sleeve 3 is clamped and fixed with the rotating sleeve-1 to form a rotating body 4. The inner peripheral surface of the positioning sleeve 3 has an annular convex edge-31, and the inner peripheral surface of the rotating sleeve-1 has an annular convex surface. Along the second 11, an annular groove 5 is formed between the annular convex edge one 31 and the annular convex edge two 11, the annular convex edge one 31 or / and the annular convex edge two 11 are sleeved on the outer peripheral surface of the rotating sleeve two 2, and the rotating sleeve two 2 There is an annular convex edge 3 21 stretching int...

Embodiment 3

[0032] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that: the locking groove 13 is arranged on the inner peripheral surface of the rotating sleeve 1 , and the buckle 32 is arranged on the outer peripheral surface of the positioning sleeve 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com