Anti-eccentric steel ball centering device

A technology of anti-eccentric wear and centralizer, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of low production efficiency and large energy consumption, and achieve the goal of prolonging service life, reducing production cost and reducing frictional resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

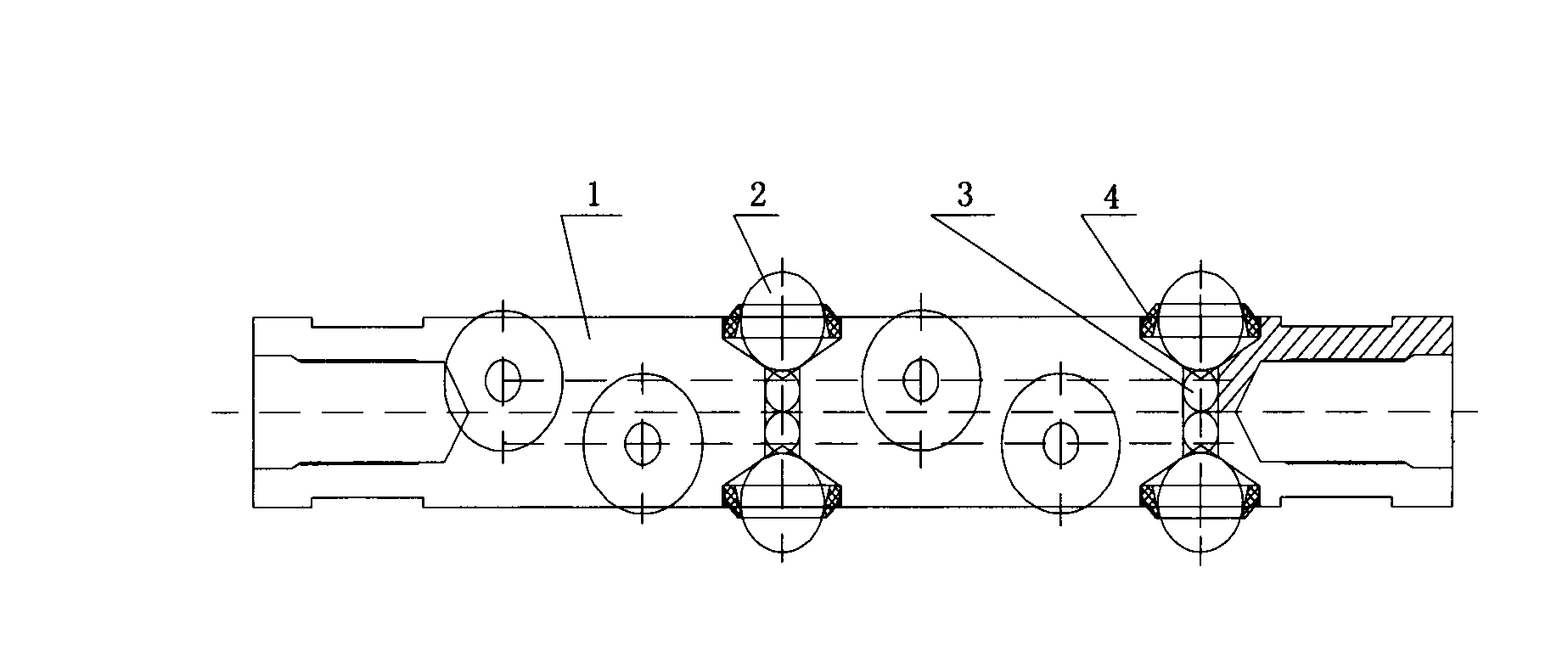

[0010] This invention is made up of parts such as rod body 1, steel ball 2, ball cover joint 4. The steel ball 2 can rotate freely in the spherical joint 4. When the invention is connected to the downhole tubing by the sucker rod (each sucker rod is connected with an anti-eccentric wear steel ball centralizer) to realize the oil pumping operation, the outside of the rod body The gap between the steel ball 2 and the inner wall of the oil pipe will be balanced to achieve the purpose of anti-eccentric wear, and the friction between the steel ball 2 and the inner wall of the oil pipe will be reduced due to the rotation of the steel ball 2. At the same time, the two large steel balls facing each other Relative rolling friction also occurs between the ball 2 and the two small steel balls 3, greatly reducing the frictional resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com