Improved sealing device of circular cooler,

A sealing device and ring cooler technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of high raw material cost and manufacturing cost, increased production cost, and increased wear of rubber seals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

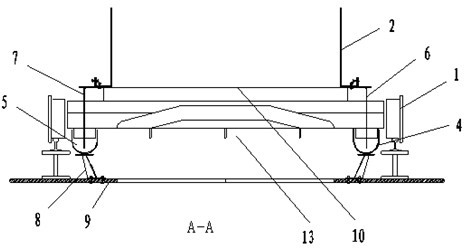

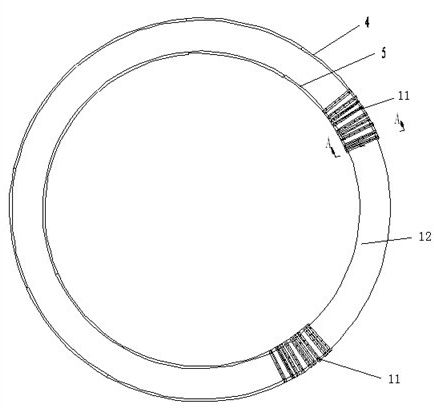

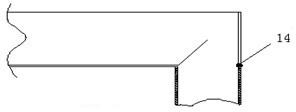

[0023] The present invention is composed of an annular sealing water tank and an annular sealing sliding plate. The annular sealing water groove and the annular sealing sliding plate can have various geometric shapes. The structure is that the annular sealing sliding plate is inserted into the annular sealing water groove, and the annular sealing water groove and the annular sealing sliding plate are installed separately At the lower end of the rotating frame 2 of the trolley 1 and below the trolley shaft, the water level difference between the left and right sides of the sealing slide plate in the sealing water tank is used to overcome (or offset) the wind pressure of the internal cooling fan of the ring cooler to achieve the ring cooler The purpose of sealing and cooling, therefore, any water sealing device designed based on this structural concept should belong to the protection scope of the present invention.

[0024] The figure shows that the basic structure of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com