Acrylate screw glue and preparation method thereof

A technology of acrylate and screw glue, applied in the field of screw glue, can solve the problems of poor wear resistance, impact on service life, poor impact resistance, etc., achieve good wear resistance, improve wear resistance, improve wettability and dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

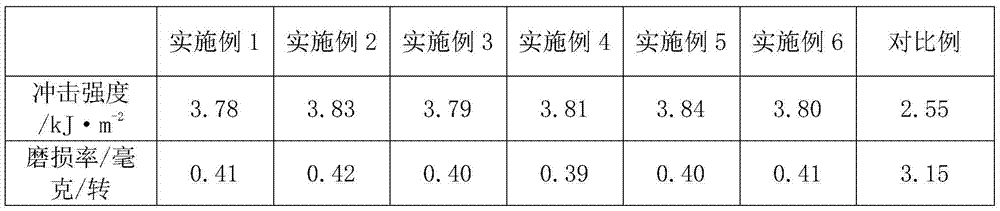

Examples

Embodiment 1

[0025] Acrylic screw glue, in parts by weight, is made of the following components: 100 parts of ethylene glycol dimethacrylate, 4 parts of dicumyl peroxide, 1 part of triethylamine, 0.4 parts of o-benzenesulfonimide 2 parts, 2 parts of alkaline thickener, 0.5 parts of organic bentonite, 2.5 parts of DBP, 0.1 part of naphthoquinone, 15 parts of IIR, 8.5 parts of titanium carbide.

[0026] The steps of its preparation method are as follows:

[0027] (1) Dissolve the rare earth coupling agent in absolute ethanol, and ultrasonically stir for 45 minutes to obtain a coupling agent emulsion with a volume fraction of 15%, add titanium carbide powder to the coupling agent emulsion and magnetically stir for 40 minutes, and move to 80 After stirring in a constant temperature oil bath at ℃ for 20 minutes, the mixed solution was obtained. After taking it out, the mixed solution was centrifuged to remove the solvent to obtain a precipitate. The precipitate was washed with deionized water f...

Embodiment 2

[0030] Acrylic screw glue, in parts by weight, is made of the following components: 100 parts of ethylene glycol dimethacrylate, 8 parts of dicumyl peroxide, 2 parts of triethylamine, 0.2 parts of o-benzenesulfonimide 1 part, 1 part of alkaline thickener, 0.4 part of organic bentonite, 2.4 parts of DBP, 0.3 part of naphthoquinone, 12.5 parts of IIR, 9.5 parts of titanium carbide.

[0031] The steps of its preparation method are as follows:

[0032] (1) Dissolve the rare earth coupling agent in absolute ethanol, and ultrasonically stir for 45 minutes to obtain a coupling agent emulsion with a volume fraction of 15%, add titanium carbide powder to the coupling agent emulsion and magnetically stir for 40 minutes, and move to 80 After stirring in a constant temperature oil bath at ℃ for 20 minutes, the mixed solution was obtained. After taking it out, the mixed solution was centrifuged to remove the solvent to obtain a precipitate. The precipitate was washed with deionized water f...

Embodiment 3

[0035] Acrylic screw glue, in parts by weight, is made of the following components: 100 parts of ethylene glycol dimethacrylate, 3 parts of dicumyl peroxide, 2.5 parts of triethylamine, 0.7 parts of o-benzenesulfonimide 1.5 parts of alkaline thickener, 0.6 parts of organic bentonite, 1.4 parts of DBP, 0.5 parts of benzoquinone, 13 parts of IIR, and 9 parts of titanium carbide.

[0036] The steps of its preparation method are as follows:

[0037] (1) Dissolve the rare earth coupling agent in absolute ethanol, and ultrasonically stir for 45 minutes to obtain a coupling agent emulsion with a volume fraction of 15%, add titanium carbide powder to the coupling agent emulsion and magnetically stir for 40 minutes, and move to 80 After stirring in a constant temperature oil bath at ℃ for 20 minutes, the mixed solution was obtained. After taking it out, the mixed solution was centrifuged to remove the solvent to obtain a precipitate. The precipitate was washed with deionized water for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com