Preparation method of etherification pretreatment type quaternary ammonium cation grafted starch sizing agent

A technology of quaternary ammonium cation grafted starch, which is applied in the field of preparation of etherified pretreated quaternary ammonium cation grafted starch slurry, can solve the problems of increasing the consumption of monomer raw materials, affecting the performance of use, increasing production costs, etc., and achieving Improve the hard and brittle defects of the size film, reduce the wear and improve the toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

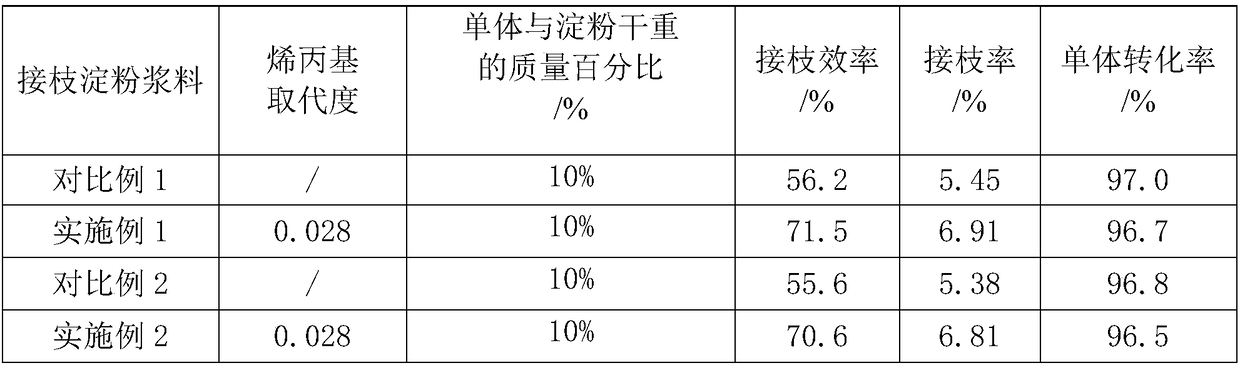

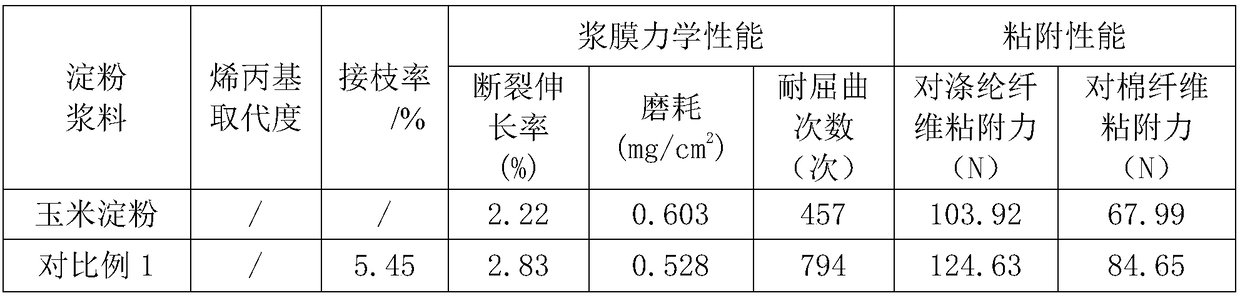

Embodiment 1

[0039] A preparation method for etherified pretreatment type quaternary ammonium cationic grafted starch slurry, comprising the following steps:

[0040] (1) Preparation of allyl etherified pretreated starch:

[0041] Take by weighing 200 grams of cornstarch (dry weight), be dispersed in the isopropanol-water solution of 80% isopropanol mass concentration, make the starch milk that mass concentration is 30%, the four-necked flask that starch milk is moved into 1000 milliliters , install a stirring device, then place it in a water bath and heat up to 30°C, and evenly add dropwise a sodium hydroxide solution with a mass concentration of 2% while stirring (the molar ratio of sodium hydroxide to allyl chloride is 1.5:1 ), after the dropwise addition, continue to stir and basify for 30 minutes; then at 30°C, add the isopropanol solution of allyl chloride evenly while stirring (the molar ratio of allyl chloride to starch is 0.04:1, Allyl chloride is dissolved in the isopropanol sol...

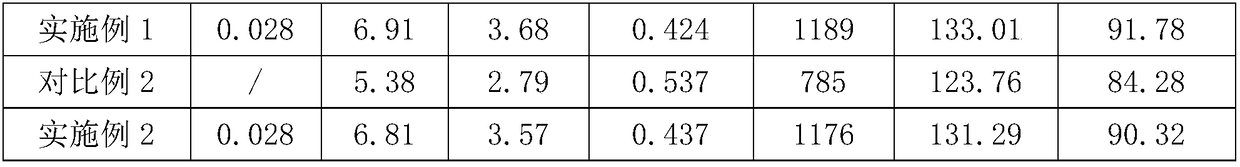

Embodiment 2

[0047] A preparation method for etherified pretreatment type quaternary ammonium cationic grafted starch slurry, comprising the following steps:

[0048] (1) Preparation of allyl etherified pretreated starch:

[0049] Take by weighing 200 grams of cornstarch (dry weight), be dispersed in the isopropanol-water solution of 80% isopropanol mass concentration, make the starch milk that mass concentration is 30%, the four-necked flask that starch milk is moved into 1000 milliliters , install a stirring device, then place it in a water bath and heat up to 30°C, and evenly add dropwise a sodium hydroxide solution with a mass concentration of 2% while stirring (the molar ratio of sodium hydroxide to allyl chloride is 1.5:1 ), after the dropwise addition, continue to stir and basify for 30 minutes; then at 30°C, add the isopropanol solution of allyl chloride evenly while stirring (the molar ratio of allyl chloride to starch is 0.04:1) , control the rate of addition so that it is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com