Automobile glass tool for mounting metal clip

An automotive glass and metal technology, which is applied in the field of automotive glass tooling devices, can solve the problems of difficulty in taking metal clips, low work efficiency, and inadequate installation, and achieves the effects of reducing labor intensity of workers, improving tooling efficiency, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

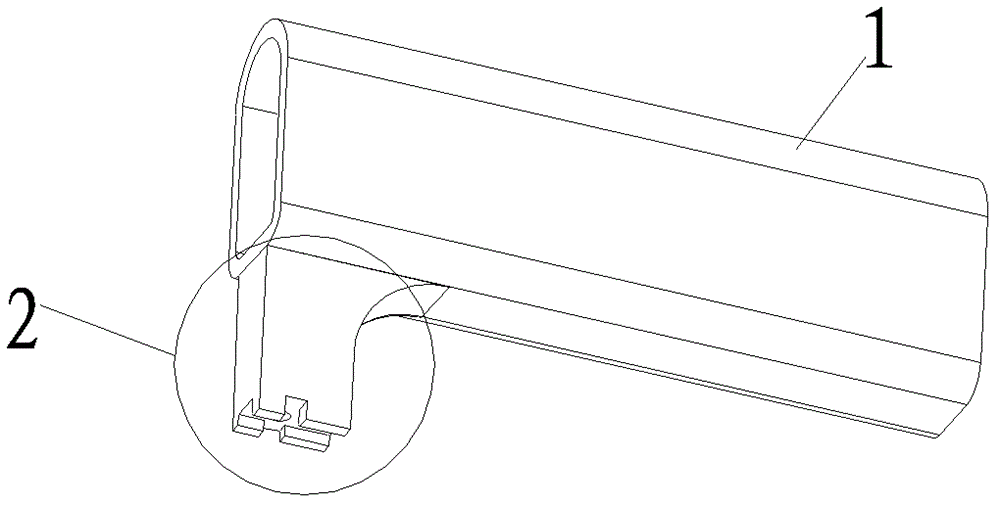

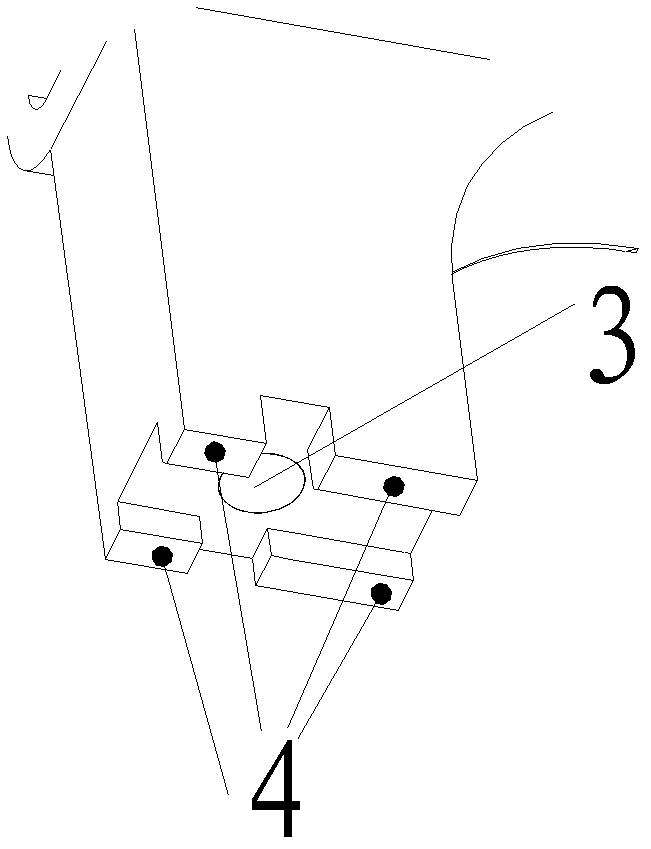

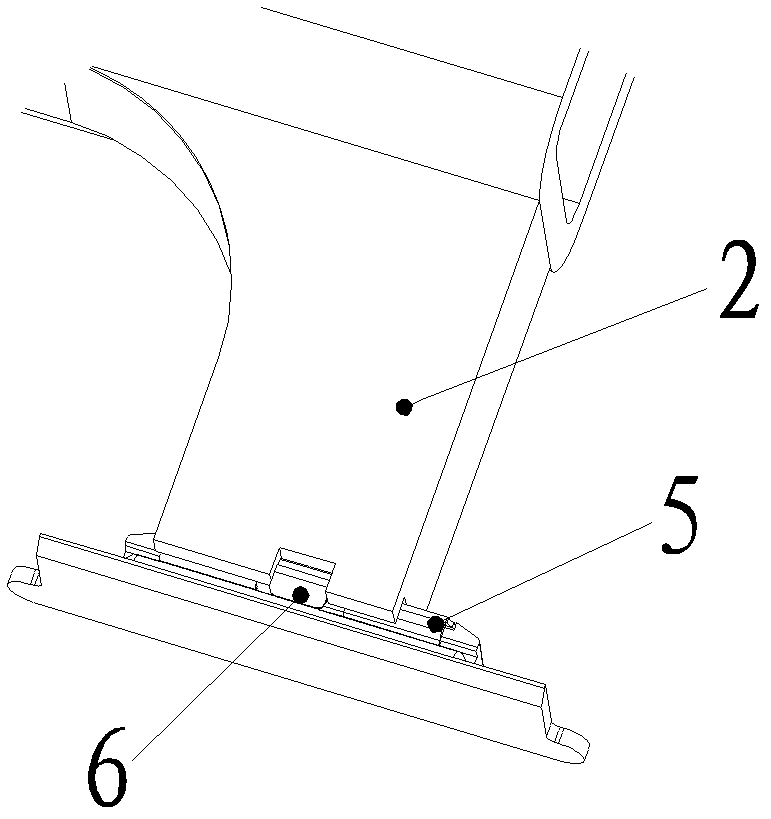

[0014] Such as Figure 1~4 As shown, a tooling device for installing metal clips on automobile glass, the device is composed of a handle 1 and a mounting head 2 at the front end of the handle, and the mounting head 2 is composed of a central cylindrical magnet 3 and a peripheral notch-shaped chuck 4, The notch-shaped clip 4 is provided with a card slot matching the two wings 6 of the metal clip 5. The metal clip 5 is directly adsorbed on the installation head 2 through the cylindrical magnet 3, and the metal clip is held by the notch-shaped clip 4. 5 positioning.

[0015] After the metal clip 5 is fixed on the installation head, rely on the notch-shaped clip 4 to act on the two wings 6 of the metal clip 5 and push forward to complete the installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com