Telescopic arm

A telescopic arm and inner arm technology, which is applied to the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of difficult control of gap adjustment accuracy, easy wear of sliders, and large errors, so as to improve the difficulty of gap adjustment and improve tooling The effect of efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

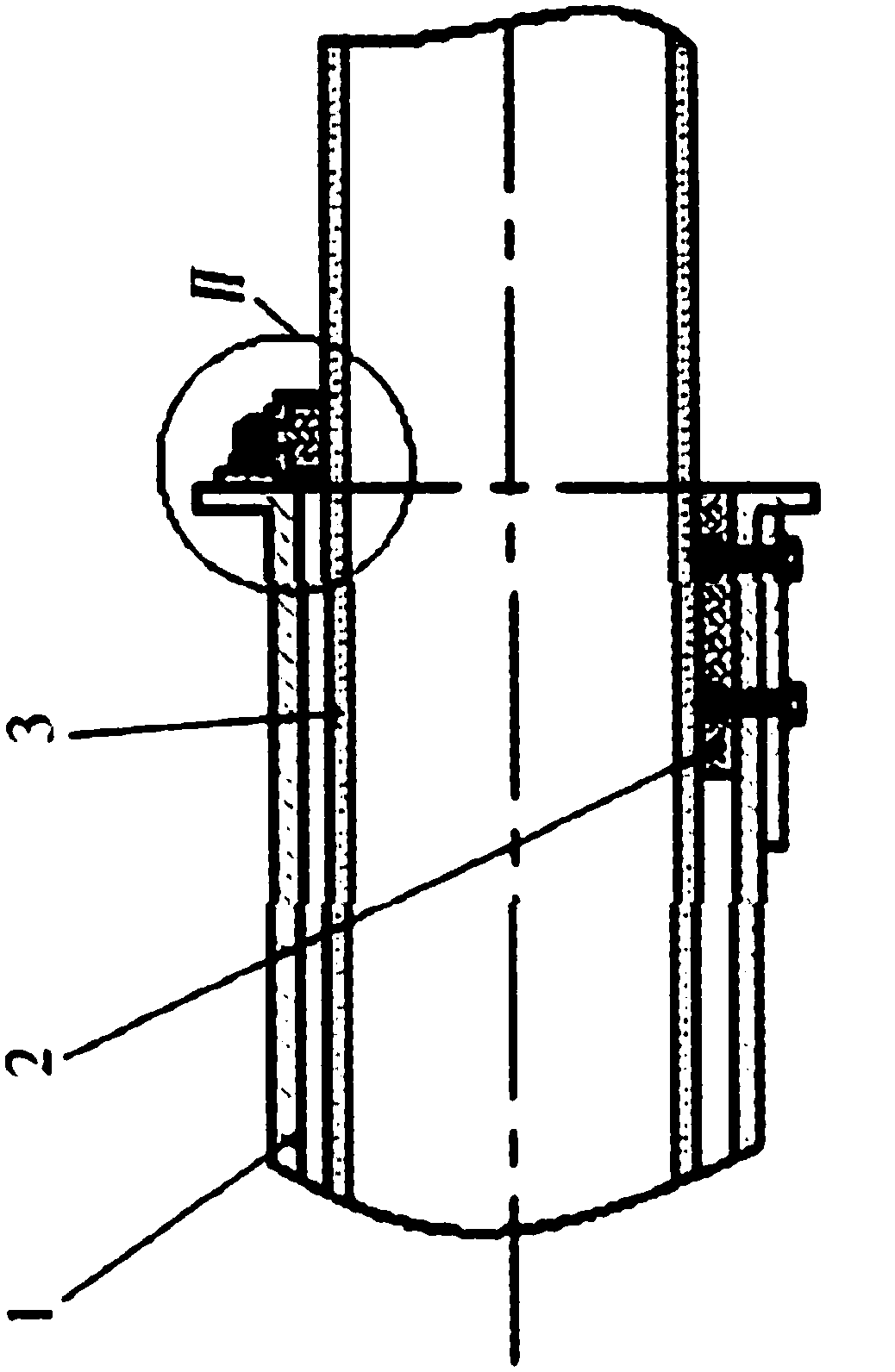

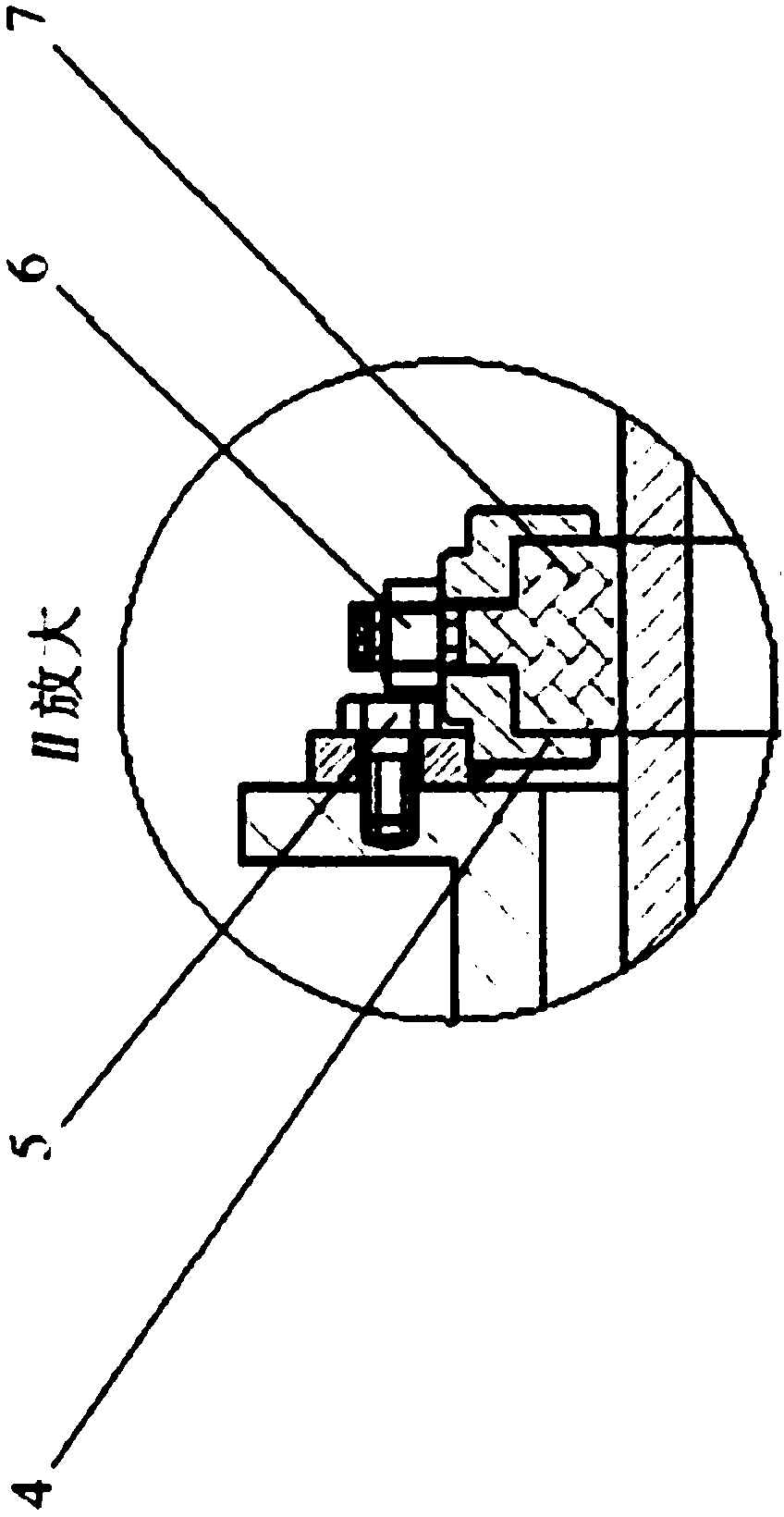

[0011] As shown in the figure, the telescopic arm of the present invention includes an outer arm 1 and an inner arm 3, and upper and lower sliders are installed between them, wherein the upper slider is composed of a mounting base 4, a columnar slider 7, and a screw 5 Composed of lock nut 6, the bottom surface of the installation base 4 is set on the outer surface of the inner arm 3, the installation base 4 is sleeved outside the columnar slider 7 and connected with the lock nut 6, and the screw 5 fixes the installation base 4 in the outer arm 1 On the surface. The bottom of the columnar slide block 7 is a cylindrical end face, and the top is a hexagonal head stud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com