Large curtain wall large panel material and unit plate overturning device

A flipping device and large panel technology, which is applied in the processing of building materials, walls, building components, etc., can solve the problems of unfavorable safety of unit panels and personnel, difficulty in turning unit panels horizontally, and difficulty in turning unit panels outside the building. It is beneficial to the protection of finished products, reducing the time of suspension and hanging, and reducing the effect of high-risk operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. For the convenience of description, it is defined that the direction of the turning device close to the outdoor in the embodiment is the front, and the opposite direction is the rear.

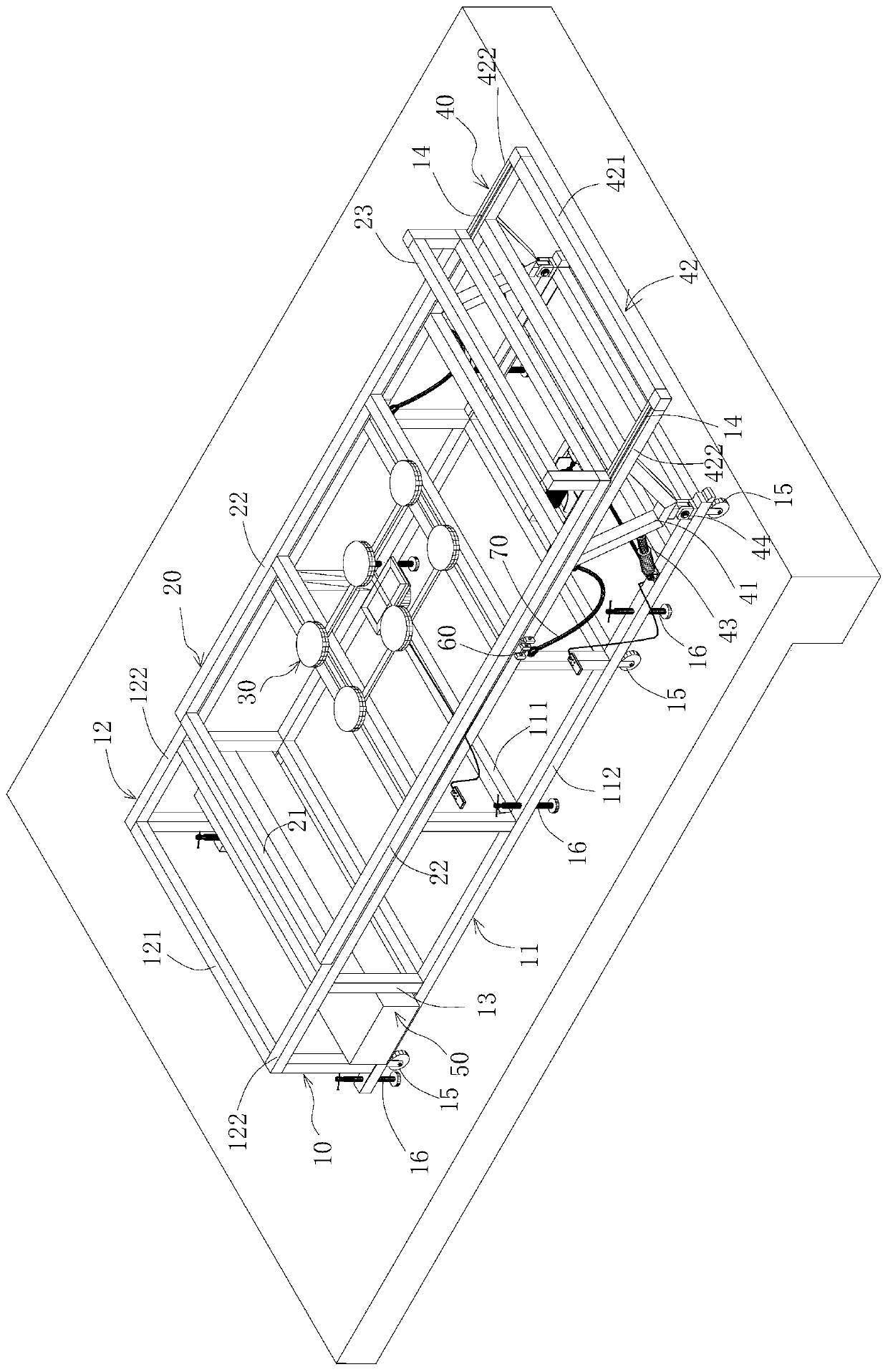

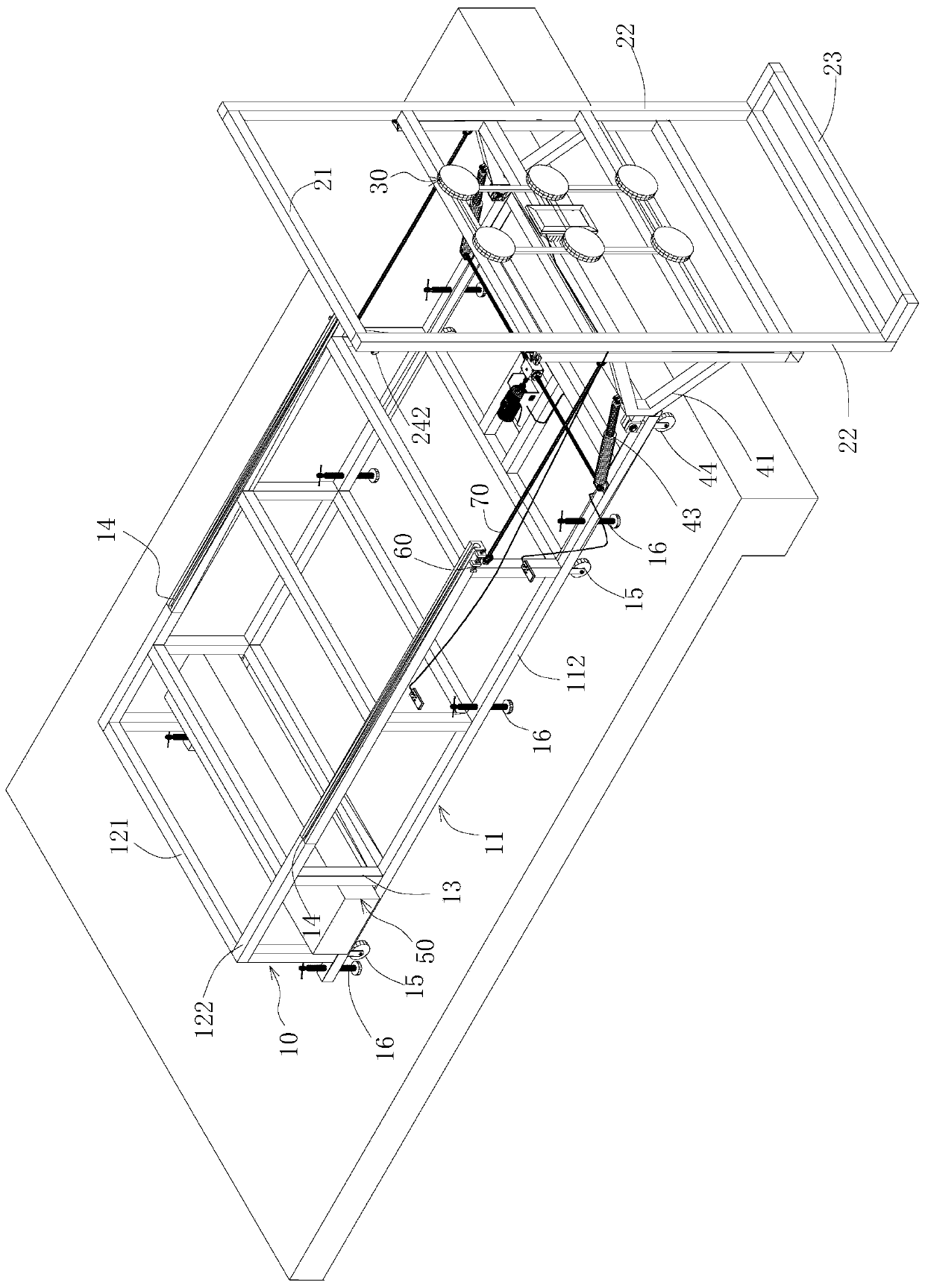

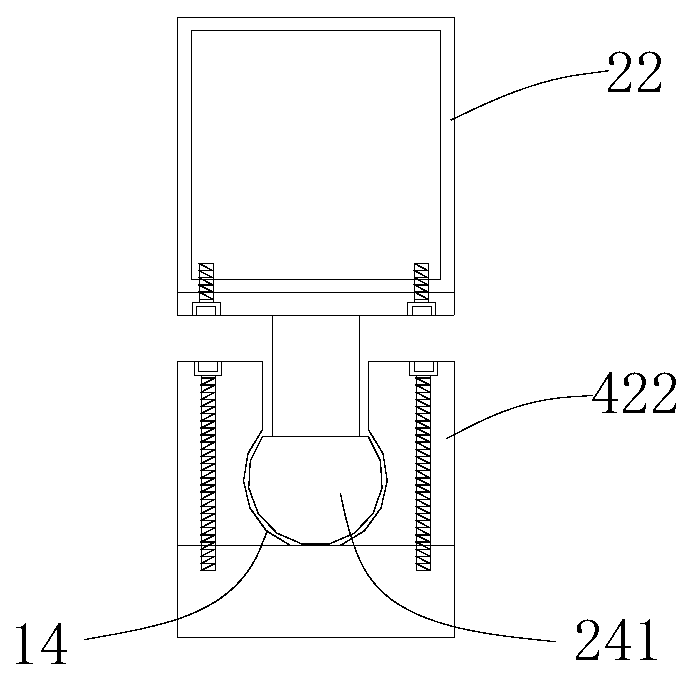

[0026] Such as Figure 1-2 As shown, the large-scale curtain wall large panel material and the unit plate turning device include a lower fixed steel frame 10, an upper sliding steel frame 20, an electric suction cup mechanism 30, a turning mechanism 40, and a counterweight 50. The upper sliding steel frame 20 is connected to the top surface of the lower fixed steel frame 10, and the turning mechanism 40 is hinged to the front end of the lower fixed steel frame 10 along the horizontal axis, and the upper sliding steel frame 20 can slide back and forth on the lower fixed steel frame 10 and the turning mechanism 40 , and under the drive of the turning mechanism 40, the front end of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com