Counterweight type roller transfer device capable of being opened and closed

The technology of conveying device and drum is applied in the field of counterweight openable and closable drum conveying device, which can solve the problems of high cost, time-consuming and laborious, low efficiency, etc., and achieve the effects of improving tooling efficiency, wide application range and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

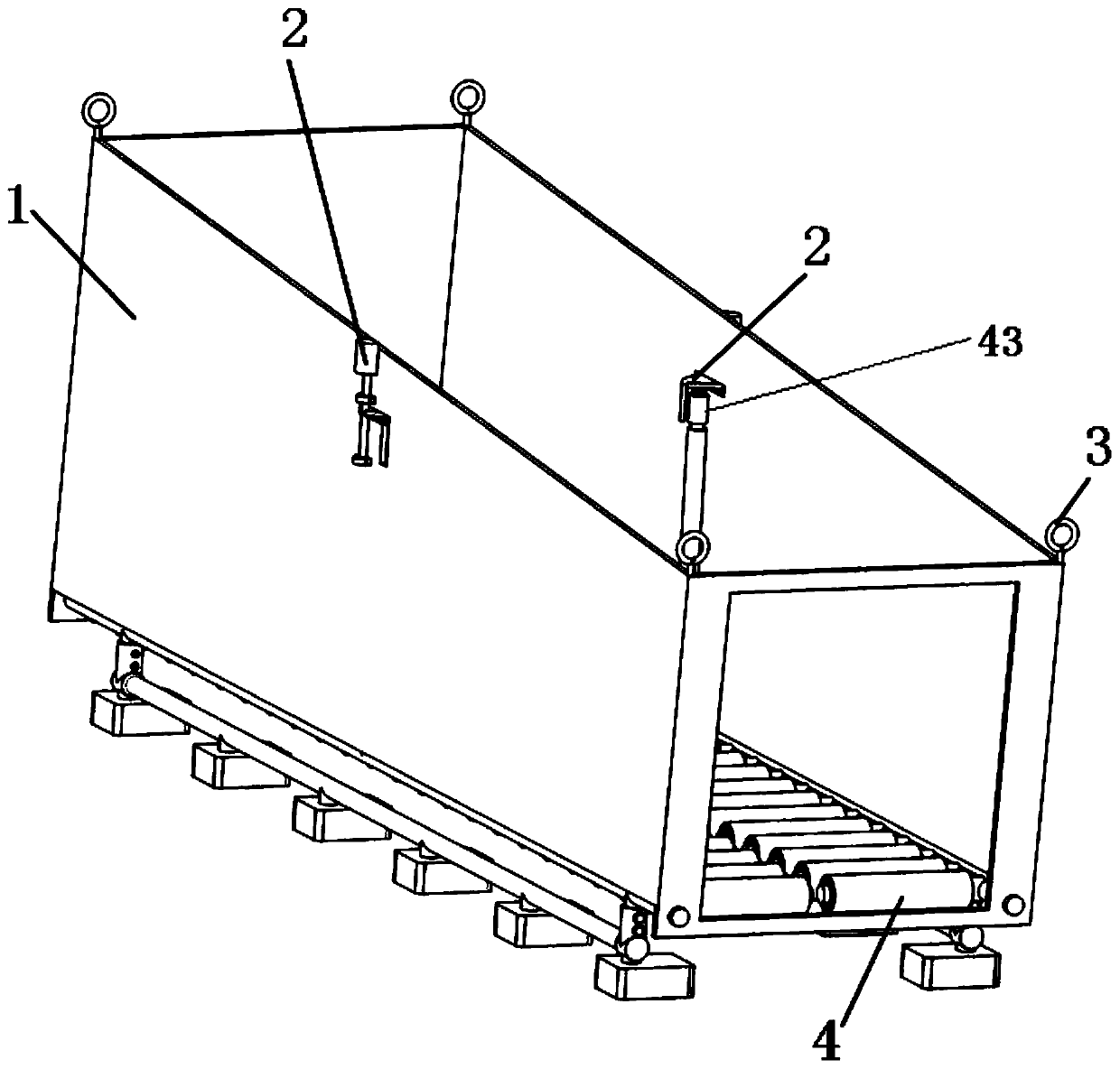

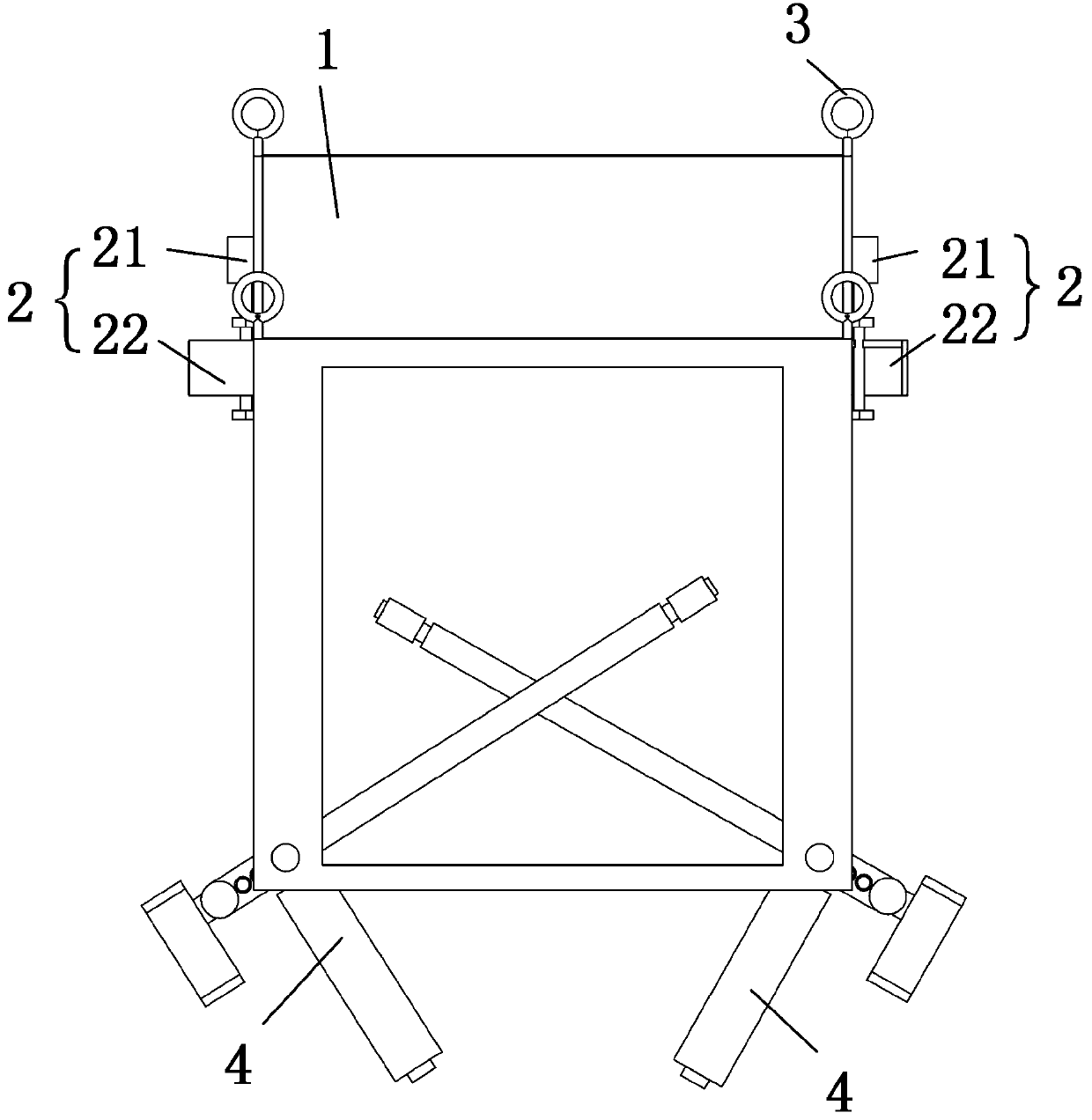

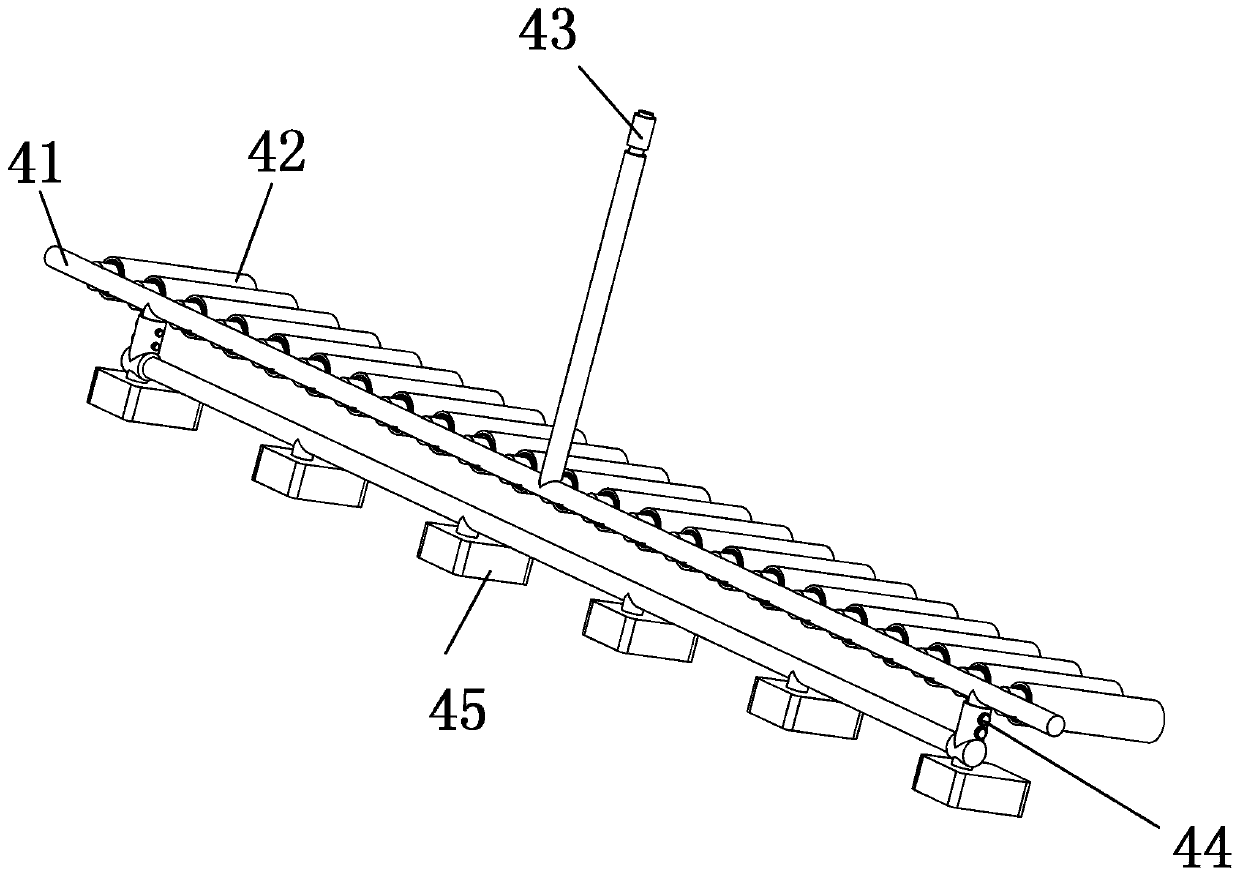

[0039] Such as figure 1 As shown, the present invention provides a counterweight type openable roller conveyor, which includes a tooling bucket 1 , a pair of rotating locking devices 2 , four suspension rings 3 and a pair of counterweight roller conveyor belts 4 . Two rotation locking devices 2 are respectively arranged on opposite side walls of the tooling bucket 1 . Four suspension rings 3 are respectively fixed on the top of the four corners of the tooling bucket 1 .

[0040] The rotation locking device 2 includes a steering gear 21 and a locking chuck 22, the steering gear 21 and the locking chuck 22 are connected by a rotating shaft, and the steering gear 21 can drive the locking chuck 22 to rotate.

[0041]The entire tooling device is connected to the crane through the lifting ring 3. Under normal working conditions, the bottom surface of the tooling bucket 1 forms an included angle of 15 degrees with the horizontal surface to ensure that the goods slide down without dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com