Decorative panel production line applying intelligent RGVs (Rail Guided Vehicle)

A production line and veneer technology, which is applied in the direction of layered products, object stacking, conveyor control devices, etc., can solve the problems of increasing enterprise input costs, troublesome transportation process, and polluting the atmosphere, so as to reduce operating costs and achieve good results. Plant environment, the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention provides a veneer production line using intelligent RGV. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

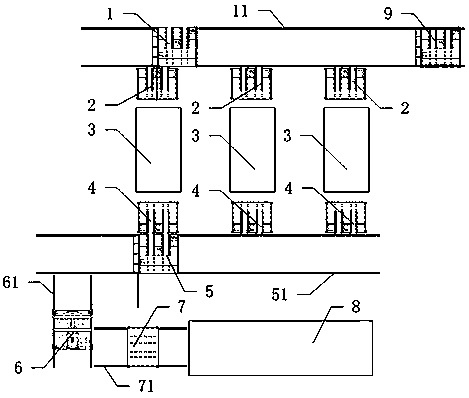

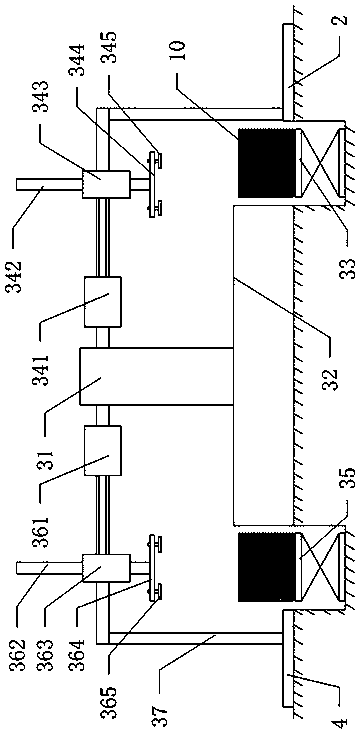

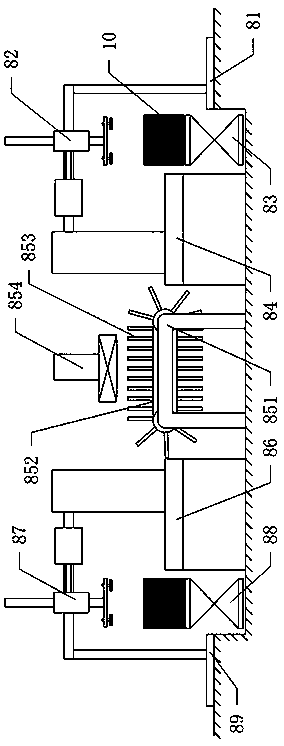

[0030] see figure 1 with Figure 5 , the present invention provides a veneer production line using intelligent RGV, which includes multiple platen equipment 3 arranged side by side, a first rail 11 provided at the feed end of multiple platen equipment 3 , a The second track 51 at the discharge end, the drying board production line 8; the first track 11 is provided with the feed RGV trolley 1 for feeding multiple platen equipment 3; Discharge RGV trolley 5; One end of the second track 51 is provided with a third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com