Clamping device for base plate

A technology of clamping mechanism and substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

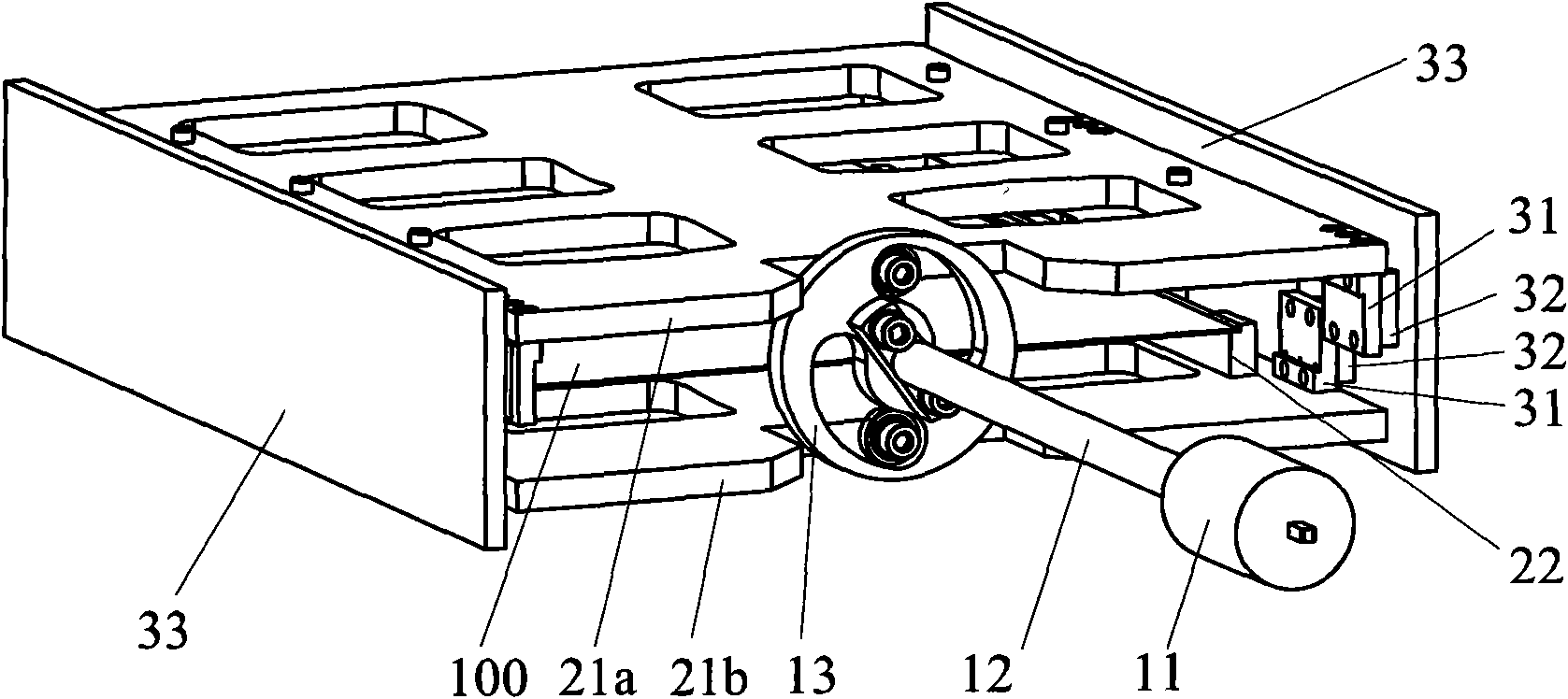

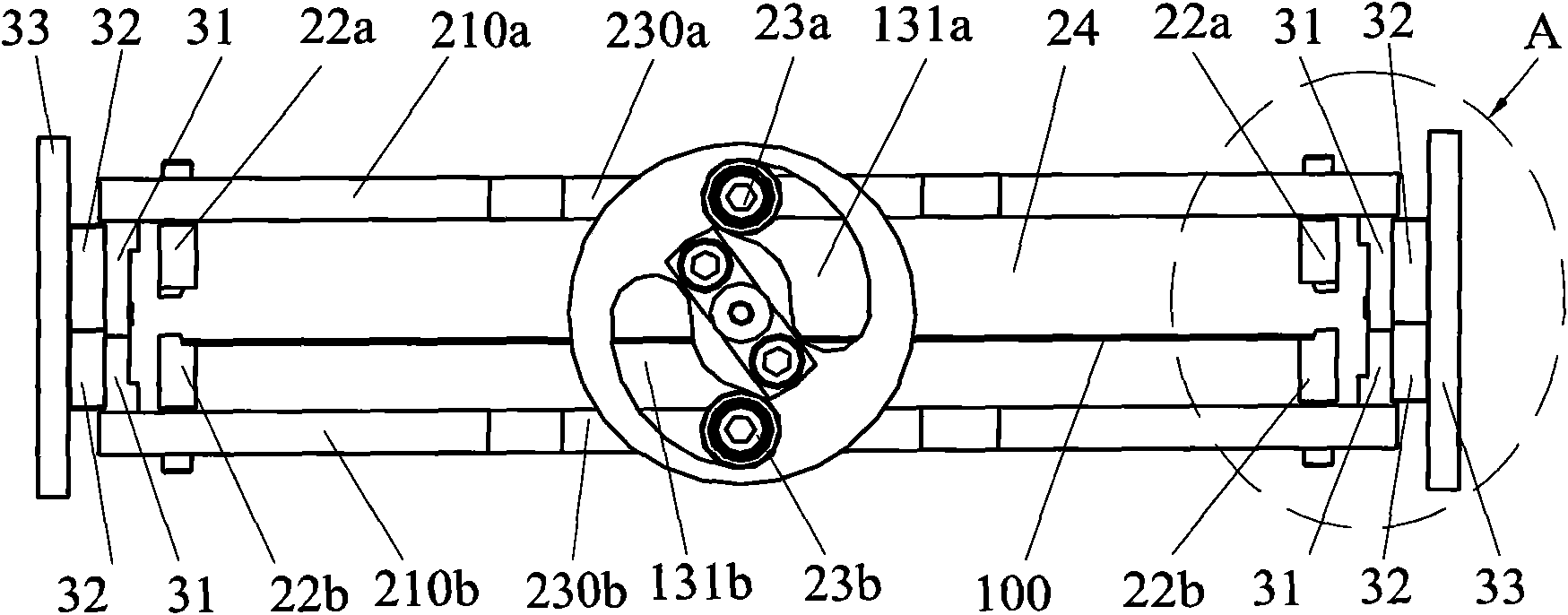

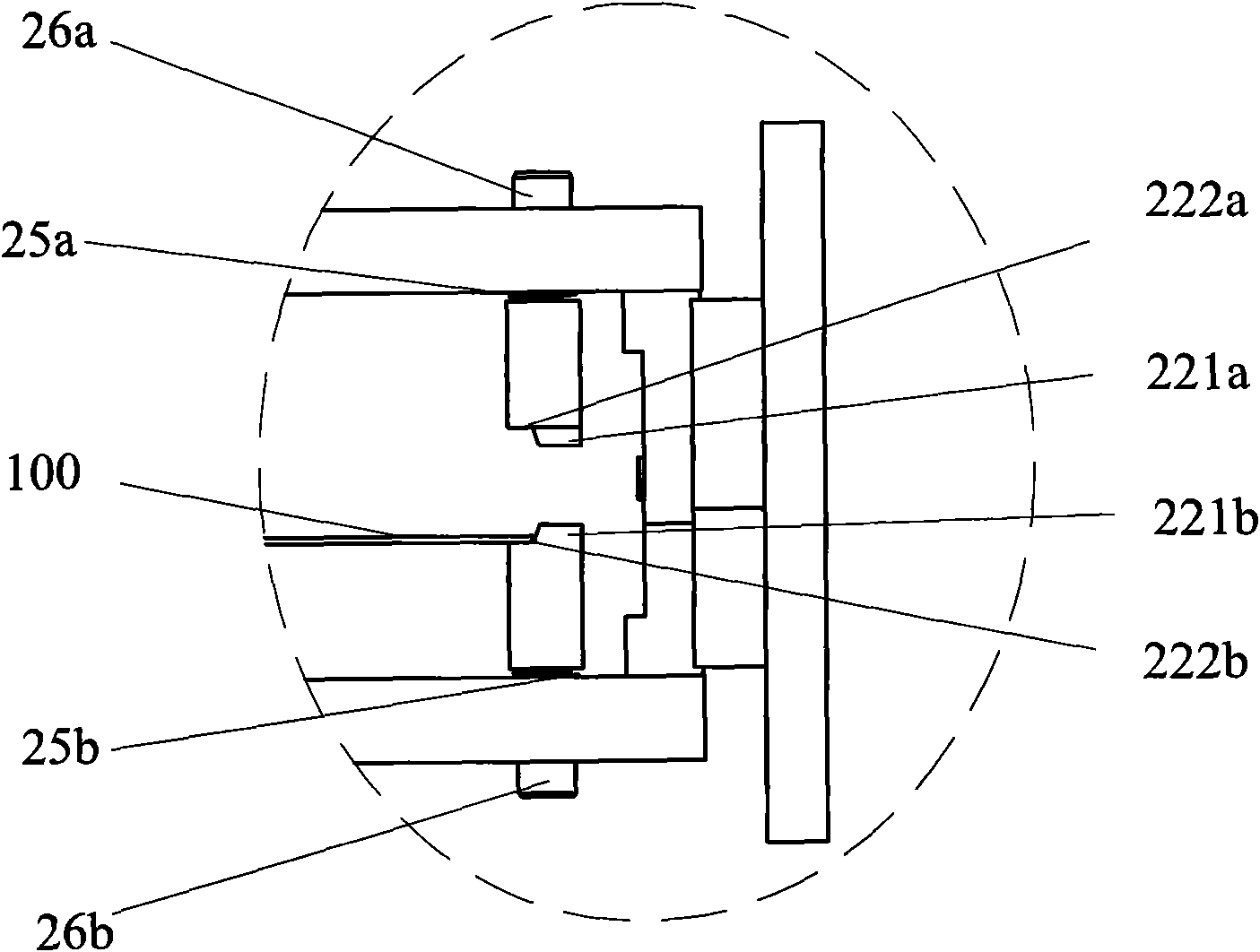

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0023] refer to Figure 1-2 , the substrate clamping mechanism of the present invention includes a driving device, the driving device includes a transmission shaft 12, a cam 13 and a driving mechanism 11 providing a power source, and the cam 13 is symmetrically provided with two arc-shaped guide grooves 131a, 131b, so One end of the transmission shaft 12 is fixedly connected to the driving mechanism 11, and the other end is fixedly connected to the cam 13, and the driving device provides power for clamping or loosening the substrate 100; the clamping device includes an upper , lower pressing plate 21a, 21b and at least one pair of pressing bar group 22, described pressing bar group 22 comprises upper and lower pressing bar 22a, 22b, each is installed on the corresponding side 210a, 210b of described upper and lower pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com