Modular variable-stroke multi-head wafer collecting mechanism

A modular and piece-collecting technology, which is applied to conveyors, conveyor objects, thin material handling, etc., can solve the problems of manual collection efficiency and low degree of mechanization, and achieve the effect of improving tool efficiency and superior control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be described in further detail below in conjunction with the specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted.

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

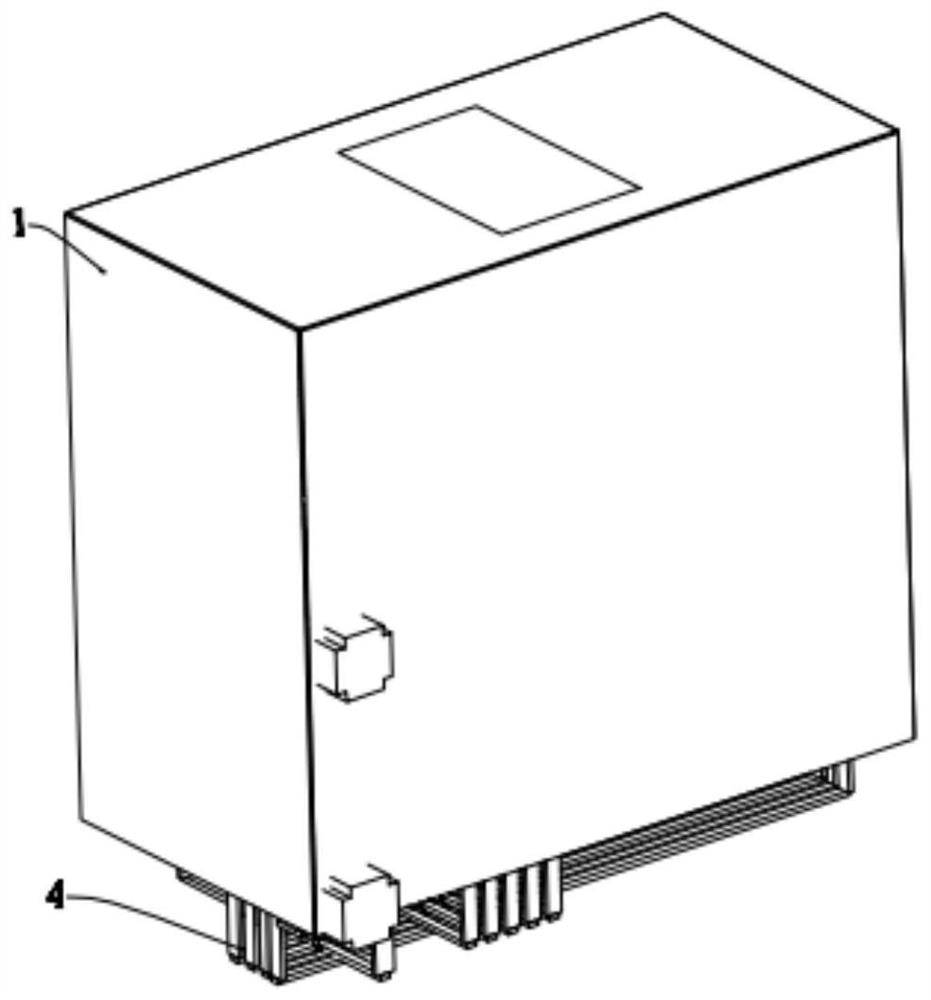

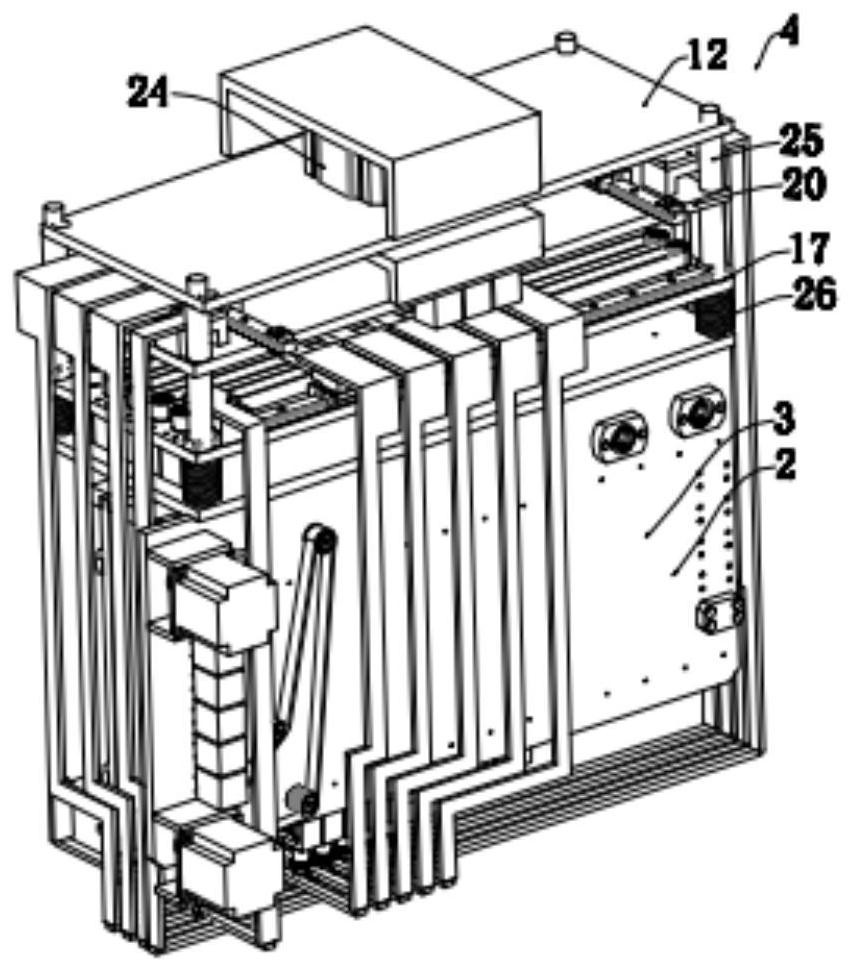

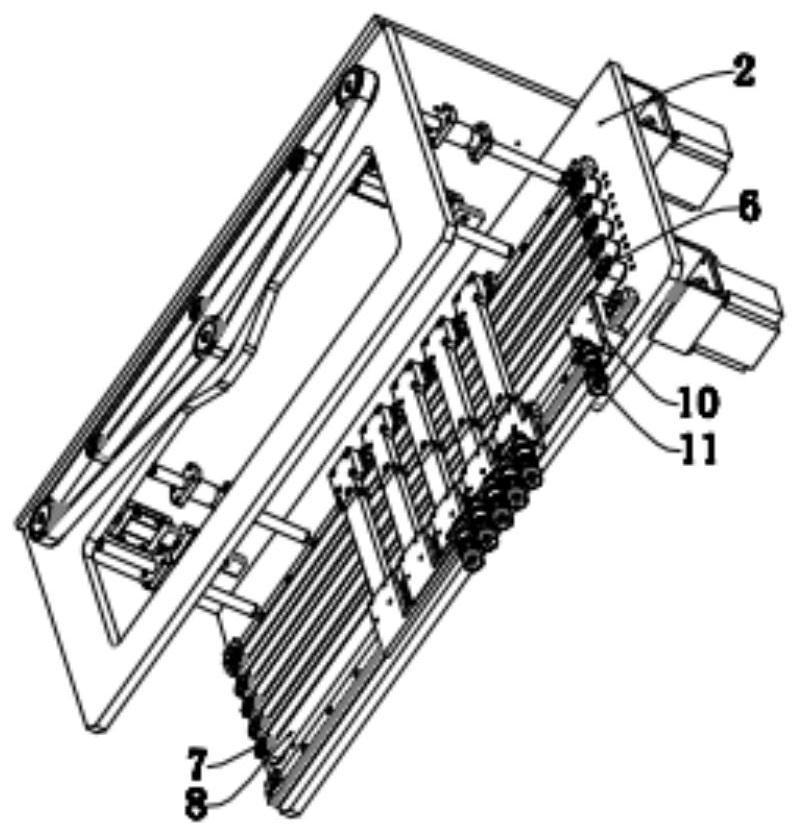

[0019] Such as Figure 1-5 As shown, the present invention is a modular variable-stroke multi-head chip collection mechanism, including a protective shell 1, a chip rack 2, a chip assembly 3 and a pick assembly 4, and the protective shell 1 is set in a hollow cavity with an open lower end. , the chip collection frame 2 is arranged in the protective shell 1, the chip collection assembly 3 is arranged on the chip collection frame 2, and the chip collection assembly 3 includes a chip collection motor 5, a chip collection runner 6, and a chip collection synchronous wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com