Blending butterfly valve

A butterfly valve and valve housing technology, applied in the field of blending butterfly valves, can solve the problems of poor control performance and blending ability, and achieve superior control performance and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

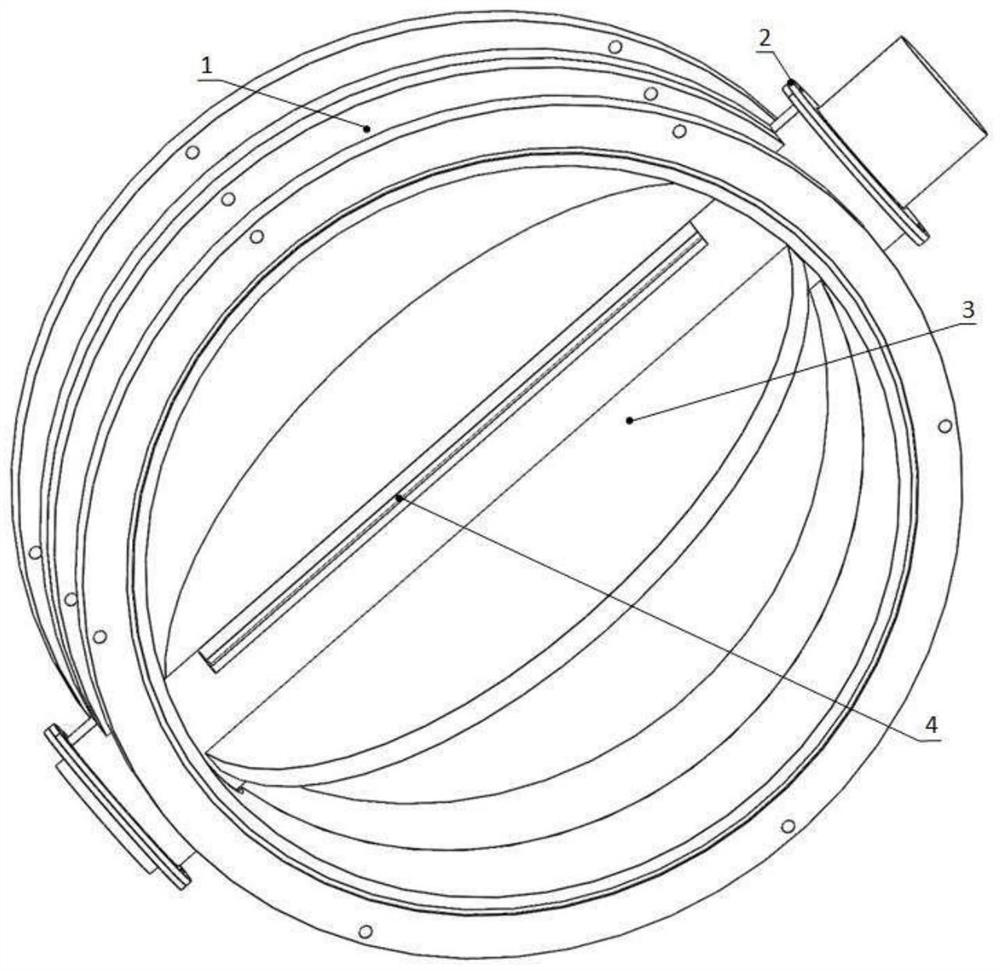

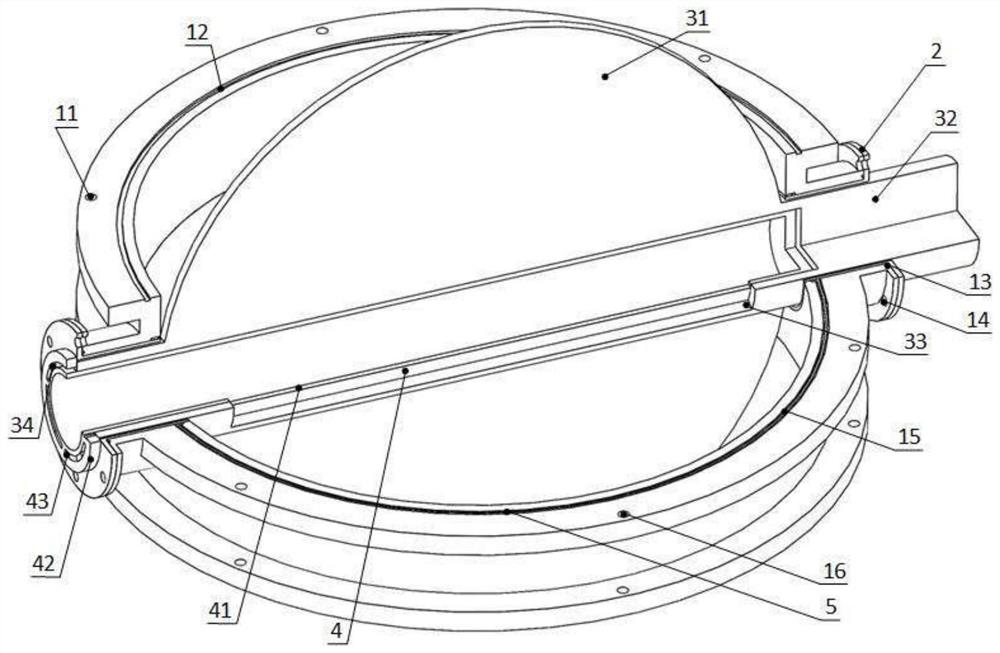

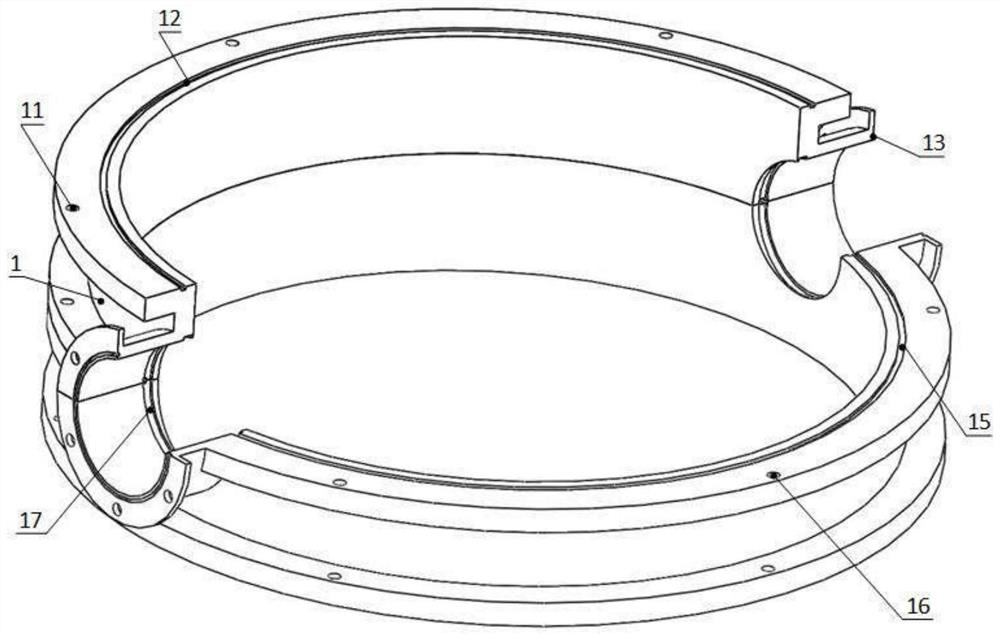

[0028] Example 1: See Figure 1-7 , the present invention provides a technical solution: a blended butterfly valve, including a valve housing main body 1, a flange cover 2, a valve plate main body 3, and a casing main body 4. The valve casing unit with a circular cavity is combined, the upper and lower ends of the valve casing unit are flange surfaces, and the flange surfaces separated by the two valve casing units are provided with a plurality of first bolt holes 11 near the outer edge The first O-shaped groove 12 is provided along the inner edge, and the two valve housing units are surrounded by two flanges 13 perpendicular to the central axis of the valve housing main body 1, and the two flanges 13 are provided with multiple a second bolt hole 14, a second O-shaped groove 15 is provided along the inner edge on the contacting flange surface of the two valve housing units and a plurality of third bolt holes 16 are arranged near the outer edge;

[0029] The two flanges 13 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com