Overturning method of large face plate material and large unit plate of large-sized curtain

A technology of large panels and plates, applied in the processing of building materials, walls, building components, etc., can solve the problems of unfavorable unit plate and personnel safety, difficulty in horizontal flipping of unit plates, bumping and scratching of unit plates, etc., which is beneficial to the protection of finished products. , Reduce the time of suspension and avoid the effect of bumping and scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

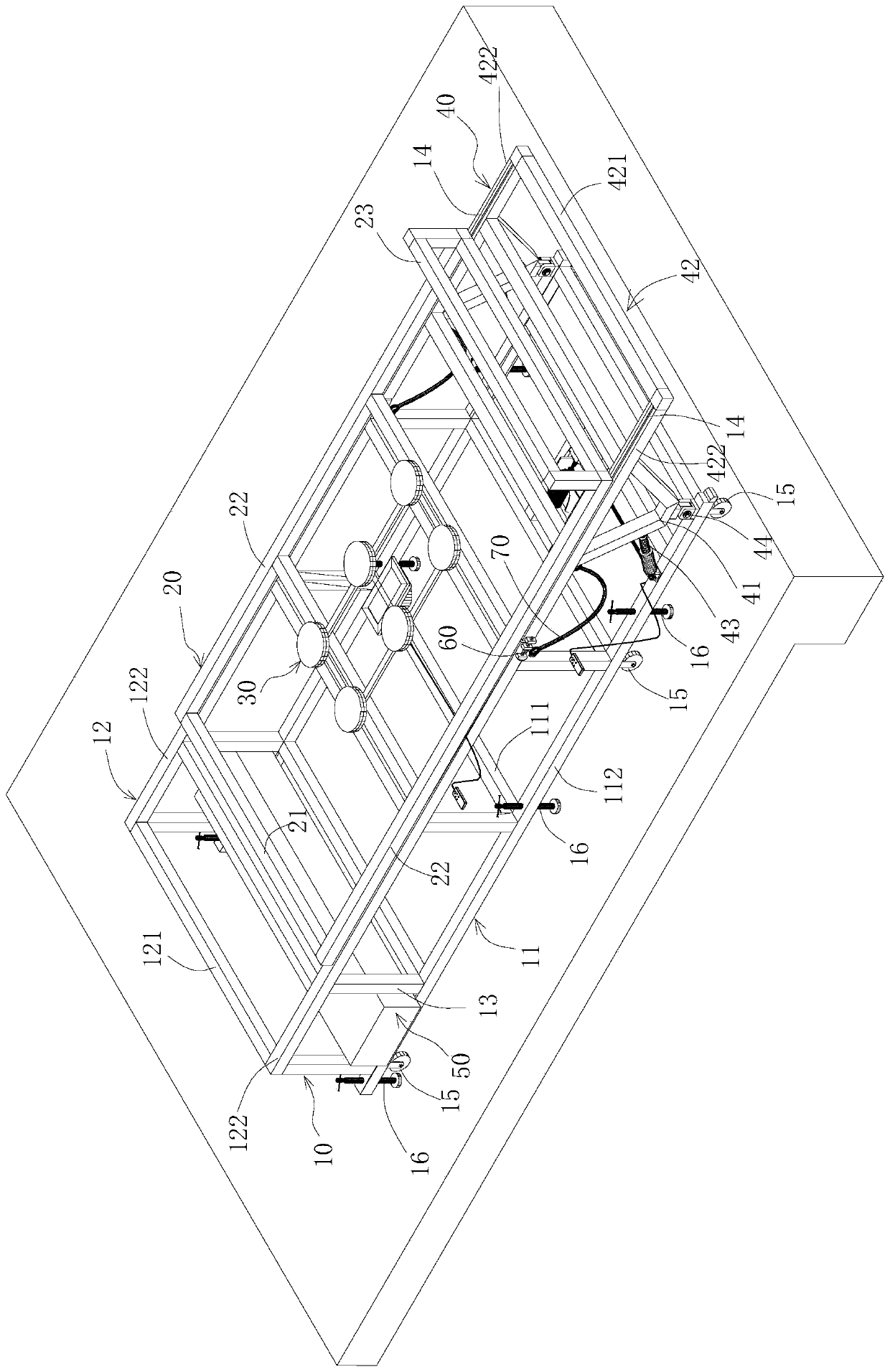

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] For the convenience of description, it is defined that the direction of the turning device close to the outdoor in the embodiment is the front, and the opposite direction is the rear.

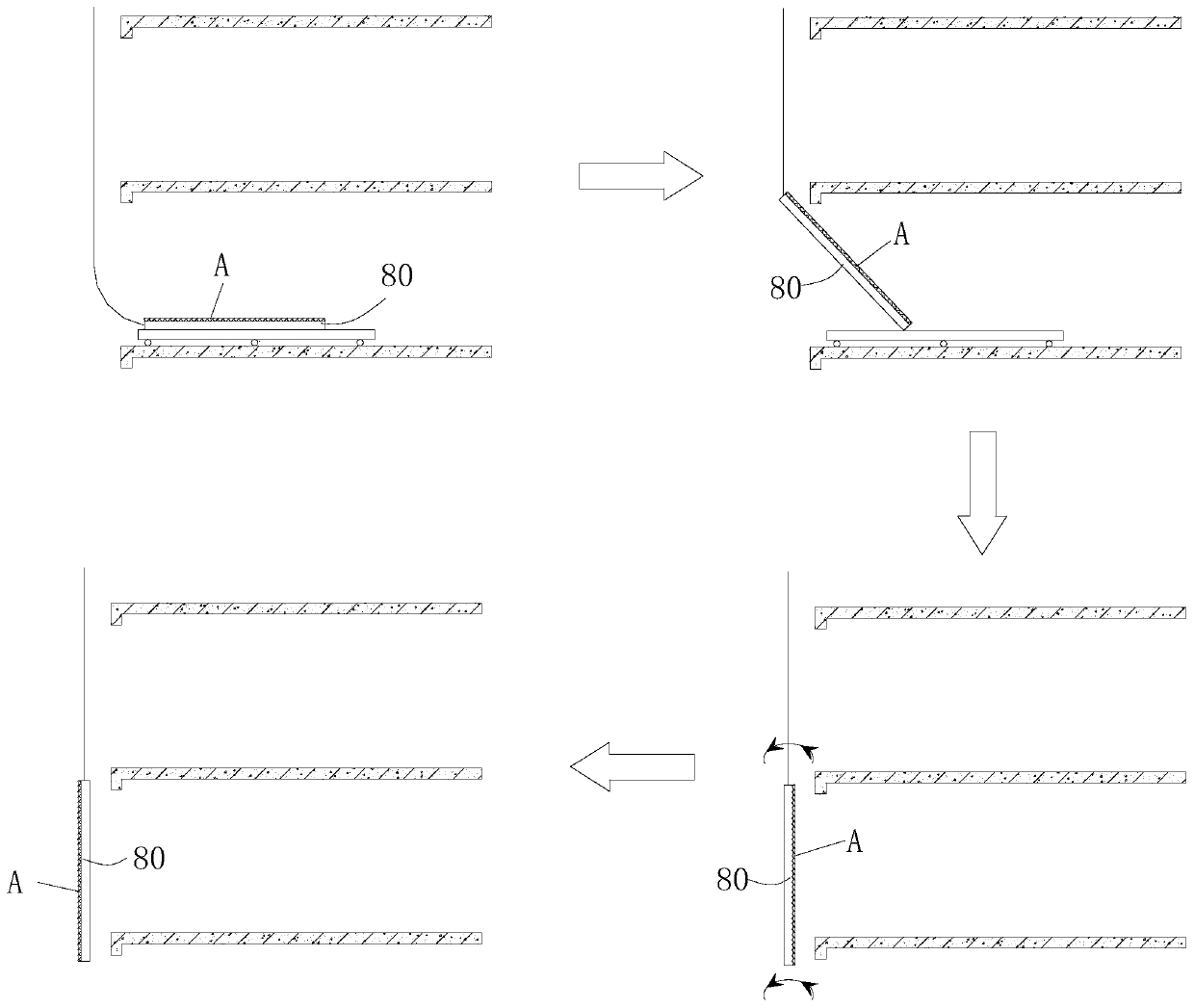

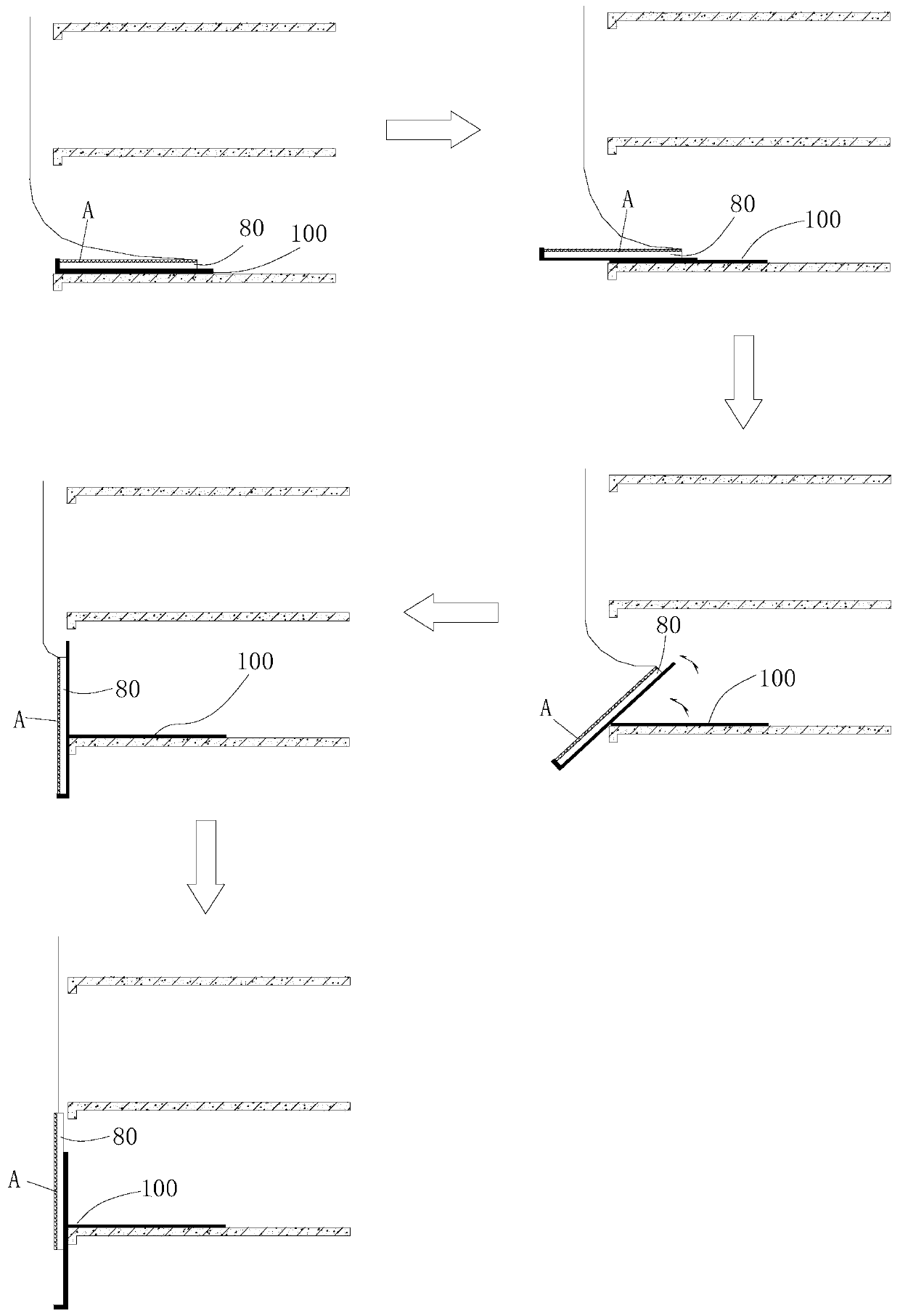

[0030] The large-scale curtain wall large-panel material and the overturning method of the unit plate of the present invention use the overturning equipment to realize the overturning of the large-scale unit plate, complete the unit plate out of the floor, the unit plate is upright, and do not need to be turned horizontally in the outdoor air, so as to achieve the purpose of safe, fast and efficient construction, such as figure 2 As shown, the specific steps are as follows:

[0031] Step 1: Move the overturning device to the edge of the floor and fix it; tie the rope for suspension to the detachable shoulder pole at the rear end of the unit plate.

[0032] Step 2, place the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com