Processing device

A processing device and positioning device technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of small tool clamping force, axial deviation of the tool, and inability of the nut to completely lock the collet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

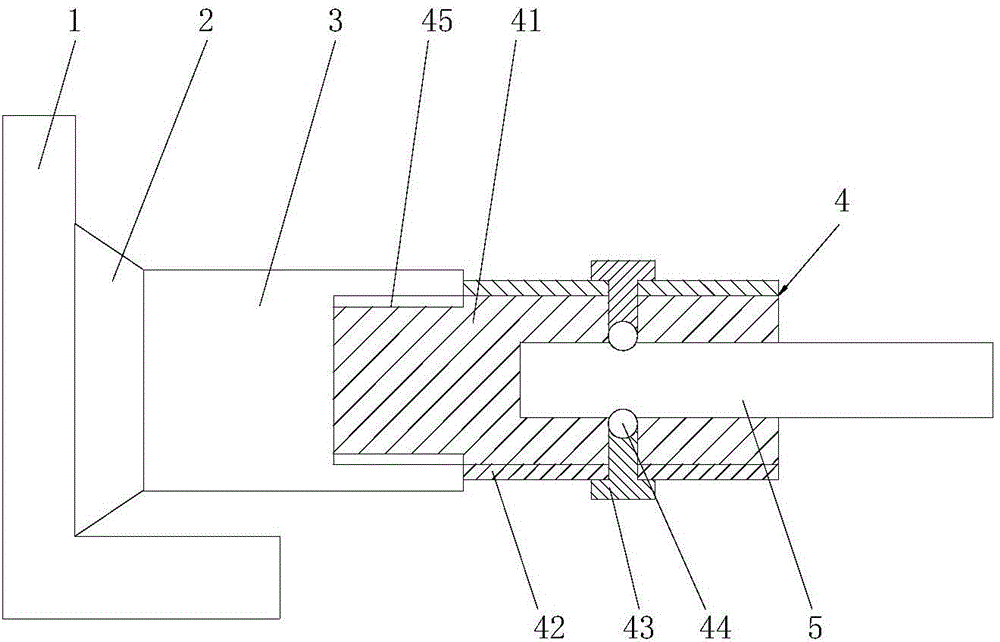

[0011] refer to figure 1 , a processing device of the present invention, comprising a spindle positioning device 1, the spindle positioning device is connected with an outer support body 2, the outer support body 2 is connected with a power transmission device 3, the power transmission device 3 is connected with a tool clamping device 4, and the tool holder Tightening device 4 is connected with cutter 5. The tool clamping device includes a tool mounting seat 41 , a jacket 42 and a locking screw 43 . A spline groove 45 is provided on the circumference of the tool mounting seat 41 , which facilitates connection with the power transmission device 3 through the spline groove. The tool mounting seat 41 is provided with a radial hole and an axial tool mounting hole. The radial hole on the tool mounting seat is composed of a straight hole section and a spherical hole section, and the spherical hole section is directly connected with the tool mounting hole. A steel ball 44 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com